A precise machining technique called metal skiving is used to thin or reduce the thickness of metal sheets or strips. To precisely obtain the appropriate thickness, entails removing thin layers of material from a metal object. Furthermore, when working with metal, skiving can be used to eliminate a thin section of material or to cut thin slices in an existing material when heat sinks and a large amount of floor space is required in comparison to the size of the metal piece.

Types of Metal Skiving

With this conventional technique, the material is manually removed from the metal surface using hand tools like shears, knives, or blades.

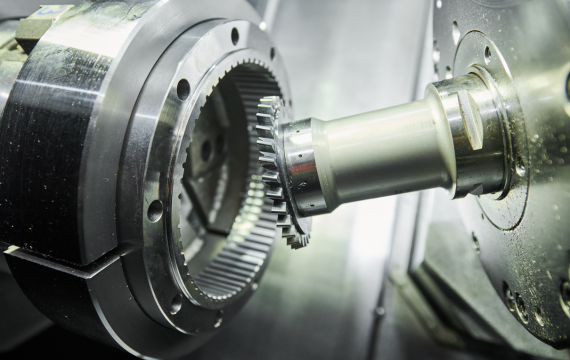

Utilizing Computer Numerical Control (CNC) technology, the metal skiving procedure is automated.

When removing material from metal sheets, mechanical skiving is done using power-driven machines that are fitted with cutting tools like slitting blades or rotary knives.

In rotary skiving, tiny layers of material are removed from the metal surface by spinning a cutting tool, frequently shaped like a disk or cylinder.

Using a cutting tool positioned vertically, vertical skiving is the process of removing material from a metal sheet or strip.

A cutting tool is used in horizontal skiving to cut a metal sheet or strip.

In a specific type of skiving known as “tapered skiving,” the metal sheet’s width or length is tapered using the skiving process.

Continuous skiving allows for the continual processing of lengthy lengths of material since the metal sheet or strip is fed constantly through the skiving machine.

Benefits of Metal Skiving

Sectors Of The Economy Typically Employ Metal Skiving

- Turbine blades

- Aircraft components

- and other critical parts

- Gears

- Transmission components

- Other critical engine parts

- Connectors

- Terminals

- Other electronic devices

- Firearms

- Missiles

- Armored vehicles

- Surgical instruments

- Components for medical equipment

- Gas

- Steam turbines

- Valves

- Pumps

- Drilling equipment

- High-end watches and clocks

Kind of Metal Materials that are Skiveable

Due to their reputation for being somewhat pliable and soft, aluminum and its alloys are a good fit for skiving procedures.

Certain titanium alloys can be skived to create thin sheets, particularly those with lower hardness values.

Skived materials frequently consist of copper and alloys based on copper, like bronze and brass.

Some mild or low-carbon steels can be skived to a desired thickness because they are more machinable.

Certain stainless steels can be skived, especially the ones with lower hardness and work-hardening tendencies.

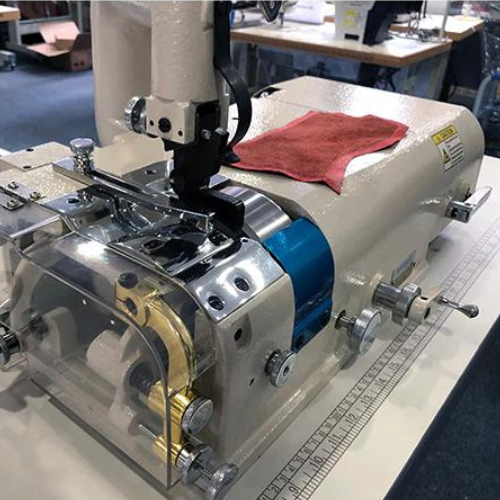

The usual method for metal skiving is to use a specific machine that has a cutting tool attached to it.

Thin shavings or chips are produced as the tool removes material when it is pressed up against the metal surface. Until the appropriate thickness is obtained, this process is repeated.

Superior surface polish, high precision, tight tolerances, and the ability to thin materials without appreciably changing their mechanical properties are some of the main benefits of metal skiving.

For the mass manufacture of thin metal components, it is also an affordable technology.

Metal carving can be done on a variety of materials and thicknesses, but it’s not always appropriate.

Processing times can increase if materials are extremely thick and need to be processed in many passes.

Moreover, during the skiving process, some materials might be more prone to warping or deformation.

Important factors like thickness, surface finish, and dimensional correctness are monitored as part of metal skiving quality control.

To guarantee exact and constant outcomes, sophisticated skiving machines may come equipped with automated controls and sensors.

The main application of metal skiving is material thinning; while it may create basic shapes, it might not be the best technique for more complicated or detailed shapes.

In the case of complex geometries, alternative machining techniques like milling or laser cutting might be better.

Both large- and small-scale manufacturing can benefit financially from metal skiving, particularly when exact thickness control is essential.

Smaller manufacturing runs, however, might take the setup expenses into account, but ensure an affordable price.