What Is Mild Steel?

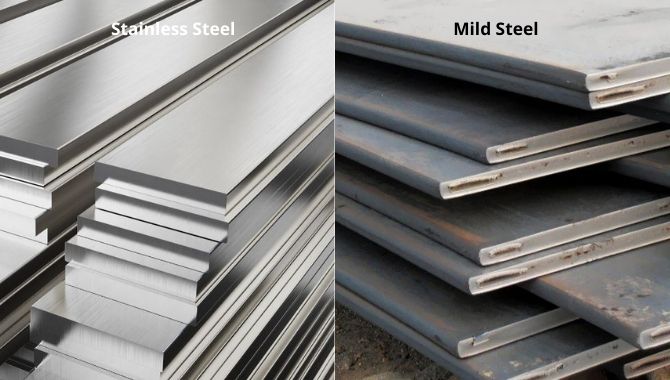

Mild steel is the most common of the types of steel. It is a ferrous metal that contains iron and carbon. Mild steel is an affordable metal with properties that come in handy in most applications.

What Is Stainless Steel

Stainless steel is a family of alloys that contain iron and chromium. It must be made up of at least 10% chromium or at most 30%. Stainless steel boasts superior qualities such as its ability to resist rusting and high strength.

Alloying Element In Mild Steel Vs. Stainless Steel

Mild steel and stainless steel have different alloying elements in them. The alloying elements are the main distinguishing factor. Mild steel is alloyed with carbon, while stainless steel is alloyed with chromium. The alloying element in both determines affordable cost the mild steel vs stainless steel price, corrosion resistance, and flexibility. The chromium in stainless steel offers excellent corrosion resistance, while the carbon in steel does not. Stainless steel is a bit more expensive than mild steel because of its alloying element (chromium).

Fabricating Mild Steel Vs. Stainless Steel

Fabricating mild steel involves mixing the required components with iron and heating them in a furnace. This is also done for stainless steel. The raw materials are placed in a furnace and heated to their melting point.

Fabricating mild steel is relatively easy compared to fabricating stainless steel. Compared to mild steel, stainless steel is much more resistant to impact because chrome is a hard alloy. Mild steel is a very malleable metal. Hence you can use it in many fabrications compared to stainless steel.

LifeSpan Of Mild Steel Vs. Stainless Steel

Stainless steel has a longer life span compared to mild steel. This is because of its ability to resist corrosion and high tensile strength. Mild steel vs stainless steel weight, mild steel is a lightweight material compared to stainless steel, which can affect its life span since it is pretty easy to destroy. Mild steel cannot resist corrosion unless a protective surface coating is added. This means that it can be damaged by rust easily.

Corrosion Resistance: Mild Steel Vs. Stainless Steel

Regarding corrosion resistance, stainless steel is highly resistant to corrosion compared to mild steel. Stainless steel is alloyed with chromium, forming chromium oxide when it reacts with oxygen. The chromium oxide protects the surface of the stainless steel from corrosion. Mild steel does not have chromium oxide. This means that it will rust whenever the surface comes into contact with moisture. Therefore, mild steel needs a protective surface coating to help prevent rust.

Welding Mild Steel Vs. Welding Stainless Steel

Mild welding steel is relatively easy regarding the weldability of mild steel and stainless steel. Mild steel is easily weldable because it is a light metal and does not have a very high tensile strength compared to stainless steel. Stainless steel, on the other hand, is a bit more challenging to weld since, during welding, you may change its shape or affect its color. Mild steel vs stainless steel has properties such as high tensile strength, which make it harder to weld.

Aesthetics: Stainless Steel Vs. Mild Steel.

If you like to paint on the surface of the metal to make it more beautiful, then you can use either mild steel or stainless steel. Stainless steel is far more attractive when it comes to aesthetics. It has a shiny, clean silver-whitish look which makes it more beautiful. Mild steel has a darkish look which is dull, making it not suitable for applications that require its aesthetics. Stainless steel has excellent corrosion resistance making it the best choice for kitchenware or fencing.

Strength Of Mild Steel Vs. Stainless Steel

Mild steel vs stainless steel tensile strength, stainless steel has high tensile strength compared to mild steel. This is because stainless steel is alloyed using chromium, a hard alloy. Mild steel has a lower tensile strength but can be strengthened by adding carbon. If you need a metal between the two that can be used frequently or withstand hard impact, you better go with stainless steel.

Brittleness Of Mild Steel Vs. Stainless Steel

More vital metals are more likely to be more brittle. Mild steel vs stainless steel radiators, in this case, stainless steel is more brittle compared to mild steel. Stainless steel would break rather than bend when there is a higher impact force. Mild steel, on the other hand, may bend rather than break when exposed to a more significant impact force. This, therefore, means mild steel is less brittle.

Malleability Of Mild Steel Vs. Stainless Steel

Mild steel vs stainless steel headers, mild steel is far more malleable compared to stainless steel. You can easily make mild steel into a new shape without breaking it. This mild steel property makes it easier to fabricate than stainless steel. Mild steel is lighter and much more flexible than stainless steel, making it malleable.

Magnetic Properties Of Stainless Steel Vs. Mild Steel

Mild steel vs stainless steel exhaust, mild steel has a high concentration of iron in it making it magnetic. Stainless steel, on the other hand, is usually not magnetic, or some may be, but it is not a guarantee. If you have any electrical or mechanical appliances, use mild steel instead of stainless steel.

Resistance To Temperature: Stainless Steel Vs. Mild Steel

Stainless steel has high-temperature resistance compared to mild steel. This means it is quite capable of resisting fire well compared to mild steel while retaining its strength.

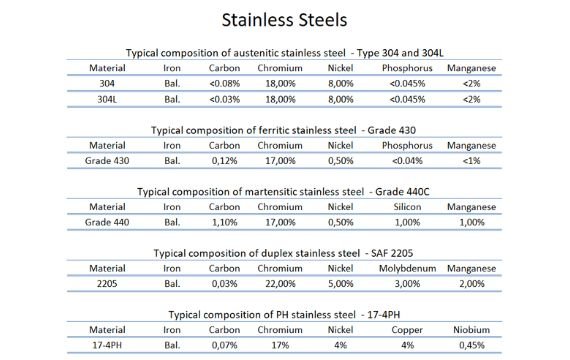

Types Or Grades Of Stainless Steel

Below are the grades of stainless steel available;

- Grade 304 is the most common among the grades of stainless steel. This is because it has high tensile strength, versatility, good corrosion resistance, and temperature resistance. These properties are why it is favored compared to the other grades.

- Grade 316 – Grade 316 is suitable for applications that include chlorides and salts. Grade 316 is resistant to chlorides making it great for such applications. Regarding tensile strength and temperature resistance, grade 304 is better than grade 316.

- Grade 430 – grade 430 has a lower tensile strength than grades 304 and 316. Its strength is enough for heavy-duty functions. One of the most remarkable properties of grade 430 is its resistance to nitric acid.

- Grade 434 – this grade is suitable for applications that require high temperatures. It has high tensile strength and excellent pitting resistance compared to grade 430.

- Grade 420 – one of the best qualities of grade 420 is its resistance to mild acids, food compounds, some alkalis, and water. It has a high tensile strength when stress is relieved and hardened compared to annealing.

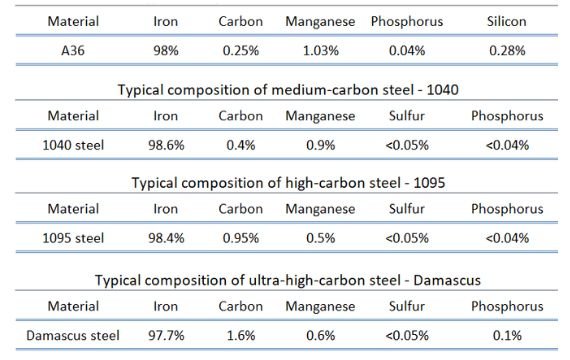

Types Of Grades Of Mild Steel

- EN 1. 1121 – you can use this grade to manufacture fasteners and cold-headed bolts. It comprises a percentage of manganese and carbon. Its main properties are good formability and ductility.

- EN 1. 0402 – this grade is suitable for welding since it has excellent weldability. It also contains a certain percentage of carbon and manganese.

- EN 1. 0301 – this grade consists of nickel, copper, aluminum, silicon, carbon, manganese, chromium, and molybdenum.

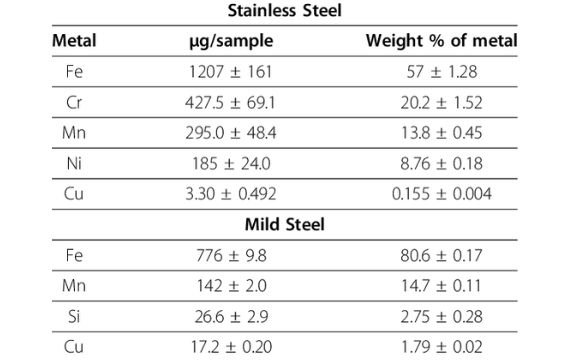

Chemical Composition On Mild Steel Vs. Stainless Steel

Difference between mild steel vs stainless steel.

Mild steel vs stainless steel density are both alloys of steel, but they are a bit different when it comes to chemical composition. Mild steel has carbon as its main component and has other components such as sulfur, aluminum, chromium, nickel, silicon, and so many more.

Stainless steel comprises chromium as its main component, and others such as copper, manganese, nickel, nitrogen, and molybdenum are in stainless steel but smaller quantities.

Each of the alloys has its function. For example, the chromium in stainless steel helps prevent rust from forming on the metal. The carbon in mild steel can help strengthen the tensile strength of mild steel if higher strength is needed.

Advantages and Disadvantages Of Stainless Steel Vs. Advantages Of Mild Steel

- Mild steel vs stainless steel strength, stainless steel has a high tensile strength and impact resistance

- It is very resistant to corrosion

- Stainless steel has an elegant and attractive appearance

- Stainless steel is a long-lasting material

- The stainless steel material is straightforward to clean and maintain

- Stainless steel is a fire retardant

- It is a highly sustainable material

- Mild steel is quite affordable compared to stainless steel

- Mild steel is lightweight, making it suitable for applications that do not require heavy-duty materials

- Mild steel is efficiently ductile, meaning you can bend it or stretch it for different shapes

- Mild steel is easily recyclable

- Mild steel is weldable

- Manufacturing stainless steel is quite difficult

- Stainless steel is relatively expensive

- It is easy to spot dirt or transfer the dirt to stainless steel material. Because of this, the material requires a lot of cleaning.

- Some stainless steel may not be magnetic. You should be careful when choosing, especially if you want a magnetic one.

- You can not heat treat mild steel. Heat treatment is mainly done on mild steel to improve properties, such as making it more robust. For mild steel, this is impossible.

- Mild steel vs stainless steel which is stronger, mild steel is not strong enough. Therefore, not suitable for applications that require strength.

- Mild steel is only suitable for low-stress applications

Applications Of Mild Steel Vs. Stainless Steel

- Medical industry

- Chemical industry

- Aircraft construction

- Food and catering

- Storage tanks

- Transportation and automotive

- Power plants

- Civil engineering

- Bridges

- Shipbuilding industry

- Offshore technology

- Automobiles

- Fencing

- Decorations

- Nails

- Signs

- Cookware

- Wire

- Furniture

- Pipelines

- Structural steel

- Machinery parts

People Also Ask:

Yes, stainless steel has many properties that make it more beneficial than mild steel.

Mild steel vs stainless steel yield strength, One of the most outstanding properties of stainless steel is its strength. It is more challenging compared to mild steel.

Yes, mild steel rusts quite quickly when exposed to moisture or water. Protective coatings cover them to prevent rust.

Yes, stainless steel is quite heavy compared to mild steel.

Additional Resources: