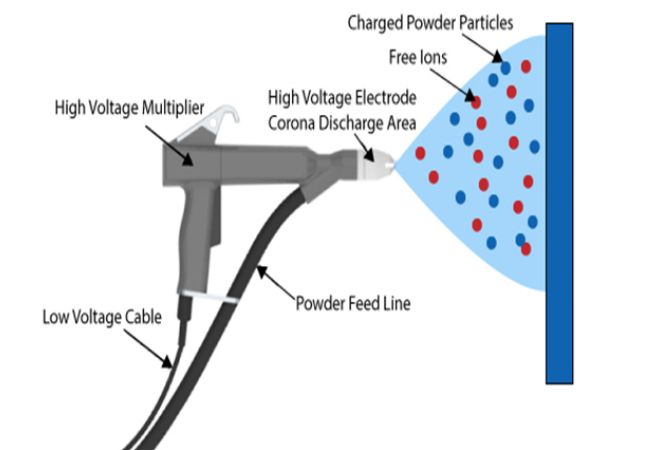

Powder coating entails electrostatically spraying dry powder on an electrically charged brass component. This charge on brass causes the powder to stick on the metal giving it a distinct look.

In this guide, you are going to learn the several benefits and usages of brass parts that have undergone powder coating.

Advantages of Powdered Coated Brass Parts

When you coat brass components with powder, their resistance to weather, color, and durability are enhanced. Let us have a look at these benefits in detail:

Brass Coated Parts are Durable

The powder coat will not fade, chip, scratch, or wear out. This means the brass parts exhibit high levels of resistance to wear and tear, making them withstand adverse elements.

In fact, an anodized brass powder coat will serve you for many years.

Color Variation

Powder coating allows you to come up with a variety of colors for your brass elements. For instance, you can have colors such as gray, beige, copper, black, etc.

An example is antique brass. The spray powder will portray an antique finish that has decorative elements. One can use black as the base color and a silver metallic color to give out the vein pattern.

Unmatched Longevity

Because the powder coat enhances the durability of these parts, they will last for long periods. All you need to do is clean them to remove dirt and debris that may accumulate over time.

High Quality Finish with Unlimited Possibilities

This process produces an even coat on the brass components compared to painting. The final product is ready for the market since you need no additional processes such as polishing or sanding.

When you apply anodized powder coat on brass, it gives off an attractive metallic finish.

You can achieve many surface finishing options including:

- Brushed powder coat finish

- Satin powder coat finish, etc.

Time Saver

Compared to liquids such as paint, powder coating cures rapidly. This means you can coat your brass parts in a short period of time. Once the coating process is done and cured, you are good to go.

Protection is Always Guaranteed

The powder coat inhibits environmental elements from reaching the raw brass metal. This protects it from environmental damage and corrosive materials.

Brass Powder Coating is Safe

As an operator, powder coating is less likely to prove hazardous to you. For instance, you will not be breathing in harmful chemicals like the ones you find when painting. Just make sure you wear the necessary protective clothing during the application process.

Powder Coated Brass Parts are Versatile

It is possible to apply a powder coat on different brass parts which find their application indifferent industries. Examples include architectural industry, automotive industry, among others.

Environmentally Friendly

The powder you are using lacks volatile organic compounds that might pollute the environment. This is due to the fact that the electrically charged brass component forces the powder to stick without using other solvents.

Minimal Waste Production

This process efficiently uses the powder that you are using thus producing less waste. It allows you to use the precise quantity for coating.

Aesthetic Appeal

Since you can incorporate different colors and finishes, the brass part can be made more attractive as well as stylish.

More resources:

- Brass Powder Coating Process – Source: KDMFAB

- Brass Finishing – Source: KDMFAB

- Powder Coating – Source: Wikipedia

Applications Of Powder Coated Brass Parts

Having seem the benefits of powder coating brass parts, it is evident that you may find it in several applications. Some of them entail the following:

1. Brass Powder Coating Hardware

Powder coat will protect the brass part from rapid wear and tear as you continually use the hardware for everyday use i.e. hinges

2. Anodized Brass Powder Coat on Tubular Hanger Rods

Besides the enhanced durability, these rods add a stylish look to the closets. Anodizing prevents the rods from tarnishing over time.

3. Powder Coated Brass Jewelry

These include necklaces and bracelets among others. They enhance the appeal of the jewelry.

4. Brass Powder Coat Wheels

Car owners can customize the look of their wheels to match their personality and style besides increasing its durability.

5. Powder Coated Brass Plumbing

These are elements you will use buildings such as water taps.

6. Powder Coat Brass Door Handles

These parts will make the interior or even the exterior of a door stylish.

7. Powder Coated Antique Brass Arm Chair Upholstered

The coat provides an aesthetic look to the chair while still blending with the cushion material.

8. Powder Coating Brass Bed

The coat enhances the appearance as you can customize the bed to match the décor of the room.

9. Powder Coating Brass Instruments

Examples of these instruments include trumpets, flutes, trombones, and saxophones, among others.

10. Powder Coating Brass Rifle Loading Tube

The powder coat in this instance will minimize wear and tear when loading cartridges in the weapon.

11. Powder Coated Automotive Parts

These include rims and trim elements that will make the car look stylish.

12. Brass Powder Coated Bathroom Fixtures

These entail faucets, towel racks etc.

13. Powder Coated Picture Frames

The frames are both durable and stylish, offering an elegant display for your photos.

14. Powder Coated Brass Sculptures

Here, you may make objects such as garden sculptures to beautify the outdoor environment.

15. Powdered Coating Lighting Fixtures

These parts are popular in both commercial and residential settings.

16. Brass Powder Electronic Parts

This element can make electronic parts like audio equipment and computer cases.

17. Powdered Brass Railing

In homes, you can make i.e. the staircase railing out of this material.

18. Powder Coated Brass Kitchenware

Since it is easy to clean and durable, you can make pats and pots out of this material.

19. Brass Powder Coated Candle Holders

The candle holders are both attractive and durable, and add to style of your place.

Conclusion

Powder coated brass parts play an integral in many industries. This is due to the many benefits they offer.

At KDM, we will help you get high quality and reliable powder coated brass parts.

More resources:

How to Remove Powder Coat on Electrical Enclosure – Source: KDM