Whether you want to invest in a new hydraulic cartridge valves, choose an efficient design, learn about parts or know the working principle, you should read this guide.

It has all information you are looking for about cartridge valve systems.

What Are Hydraulic Cartridge Valves

Hydraulic cartridge valves are mechanical devices that you can apply in your hydraulic system to regulate fluid flow. Some of the regulatory uses include shutting down a line, redirecting the hydraulic fluid and controlling the flow rate.

Their compact nature allows them to be easily integrated on the applications manifold block. You will find them in very basic designs with few movable parts that make them more efficient.

Benefits of Hydraulic Cartridge Valves

These valves can offer you so many benefits when you apply them to your hydraulic systems. Consider the following as some of these advantages that you are bound to enjoy:

· Easy To Maintain

When you find a faulty valve, you can easily replace it without tearing down your whole hydraulic system. This will greatly improve your downtime and reduce your maintenance costs.

· Versatile

You can find these valves in various sizes, designs, and configurations such as flow, directional, and pressure control valves. This means that you cannot lack a cartridge valve that can fit into any of your hydraulic applications.

· Compact

The fact that they are compact makes them easy for you to install directly onto your applications manifold block. This will save you some space especially if your hydraulic system is space-constrained.

· Increased Flow Rates

If you’re handling high-pressure hydraulic applications, then these valves are up to the challenge. They can handle very high flow rates that have high fluid pressure.

· Customizable

You can easily contact your valve manufacturer if your application has specific valve requirements for customization. You can be accorded a variety of valves ranging in size and pressure ratings suitable for your application.

· Reduced Leakages

You will realize that Hydraulic Cartridge Valve connections are very minimal. This greatly reduces the chances of any leakages happening.

Furthermore, the seals and O-rings they contain serve to arrest leakages even more. This assures you of a very efficient and reliable hydraulic system.

Types of Hydraulic Cartridge Valves

Despite having a common operating form, you will still find Hydraulic Cartridge Valves in many types, shapes, and designs.

These valves fall under two broad categories, slip-in cartridge valves and screw-in cartridge valves. You will later notice from our broad analysis that they have very few differences.

Let’s take an example of Screw-in cartridge valves, we mostly use them in hydraulic systems requiring minimal maintenance. You will find them as single bodies in the system or inserted into the applications manifold block.

On the other hand, slip-in cartridge valves are another name for 2/2-way valves and cartridge logic valves. You will need to have an additional pilot control valve for them to work.

That said, let us now go through the different types of Hydraulic Cartridge Valves:

· Cartridge Shuttle Valves

This valve can permit fluid flow coming from two different sources. They have a seat/ball in the design in addition to a g1 8 mounting thread.

The fluid enters one end of the valve and uses pressure to push the ball to the other end to prevent backflow. You can use this valve in instrumentation and control systems, braking systems that use hydraulics among others.

· Cartridge Solenoid Valve

This is so for the most common Hydraulic Cartridge Valves you will find in use. You can automate your fluid flow control or operate this valve remotely.

It works by either being energized or de-energized using electrical field current that is converted to mechanical energy. When energized, the armature or plunger is pulled by the magnetic field against the spring force.

When de-energized, the armature or plunger assumes its initial position. You can use this valve for industrial applications, home appliances like washing machines, and in automation.

· Cartridge Needle Flow Control Valve

This needle valve has a basic structure consisting of a valve stem and a needle. If you want to adjust the flow rate, you just adjust the needle until your desired flow rate is achieved.

You can adjust the needle till the end to restrict the flow rate. Alternatively, you can counter-adjust it to achieve free fluid flow.

· Cartridge Ball-Type Flow Control Valve

This valve has a ball having a hole at the center and is attached to a handle. Turning the handle aligns it with the valve cavity allowing fluid flow while the opposite prevents fluid flow by obstructing the hole.

· Cartridge Load-Holding Valves

They are counterbalance valves that you can use to reduce any irregular motion within an actuator. Despite their small size, they prevent actuator failure when there is hose failure that can lead to sudden free-fall.

· Cartridge Check Valve

This one-way valve is unidirectional and prevents fluid backflow. Since they don’t contain any handle or stem in their design, you can automatically run them independently.

You can find various types of check valves such as:

- In-Line Check Valves: has a spring that closes it when the pressure goes below the valve’s cracking pressure.

- Stop Check Valves: has an override control to cut off the liquid flow

- Lift Check Valve: has a liftable disc that rises with increased fluid flow

· Cartridge Pressure Relief Valves

Let’s not confuse these valves with safety valves. When your hydraulic system exceeds its normal pressure level, you can protect it using this valve.

They immediately open when your hydraulic system pressure exceeds normal and de-pressurizes it. It can release both the generated pressure and the excess pressure.

· Cartridge Pressure Reducing Valves

Though same as the pressure control valves, it serves a different function in your hydraulic system. However, its main function is reducing pressure flow strictly in your system’s exit port.

It will carry out this whether or not changes in the force may occur afterward in the hydraulic system upstream current.

· Cartridge Sequence Valves

As the name implies, this is your choice of valve in applications that run in sequence. When one operation ends and another one begins, the various actuators also have to run in sequence.

You can use this valve to alter the sequence of your hydraulic cylinders to achieve your desired sequence. Their design is of two-way valves but with their spring chambers positioned on the outlet port.

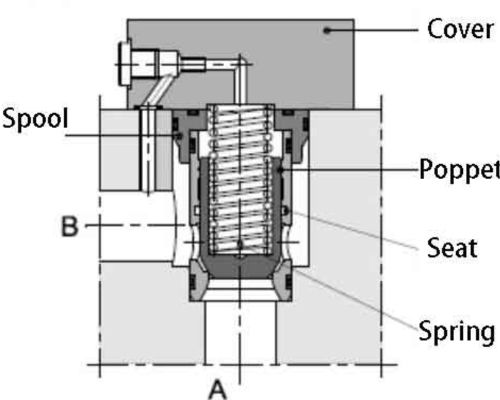

Parts Of A Hydraulic Cartridge Valve

You will find common but differently structured Hydraulic Cartridge Valve parts based on their different designs. Let us have a brief overview of some of these parts:

· Cartridge

This is what defines this valve. As for the screw-in type of Hydraulic Cartridge Valve, it lodges directly into the application units manifold block.

Now you can guess what controls the whole flow process of the hydraulic fluid. All that mechanism is contained in the cartridge.

· Housing

This is the cover that protects the cartridge. The part material is normally steel but any other durable material still gets the work done.

The design of the housing is in such a way that it can handle extreme temperatures and pressure. It can also withstand vibrations and slight knocks.

· Seal

Its component material is usually rubber but you can also get it in various elastomeric materials. It is a very vital component since it hinders any possible leakage of hydraulic fluid from the valve.

· Spring

You will find springs made of steel but other durable metal materials can serve the same purpose. It is the component that regulates any movement that the Valve mechanism carries out.

· O-ring

This thing is designed to produce a hermetic seal between where the cartridge valve is mounted and the valve itself. It is commonly made of rubber.

How Hydraulic Cartridge Valves Work

You will find several variations of Hydraulic Cartridge Valves with different designs. However, their operating principles are similar.

Let’s take an example of the hydraulic cartridge with ports at ports having equal areas. They are normally unidirectional but without a communication hole to allow hydraulic fluid to enter.

To understand this better, we have to first know its main components. These are a sleeve, a valve poppet, and a closing spring.

The hydraulic fluid will enter the valve from either port and open the holding poppet by applying pressure on it. This will allow the fluid to flow through and around your hydraulic system.

When the valve is closed, a spring maintains the poppet in it position. However, the spring is lightweight and can easily be moved by fluid pressure to allow the passage of the fluid.

You can find these springs with various strength levels depending on your application. However, the most common designs range between 50 to 75 psi.

Features Of Hydraulic Cartridge Valves

You can easily identify these valves using several features that are unique to them. Let us briefly analyze some of the common ones you can easily come across:

- They can perform several functions in a single mounting on your hydraulic system

- Their switching time is very fast and soft

- They contain a single contact point within them

- They can operate very well under high pressure with low-pressure drop

- They have a large flow range

- They are not easily prone to contamination

- They have minimal to no leakages if properly maintained

Hydraulic Cartridge Valve Materials

Various materials are used in the manufacture of Hydraulic Cartridge Valves. These materials must be durable and can sustain high temperatures and pressure.

Since you will expose your cartridge valve to corrosive environments, the material should also be corrosion-resistant. Some of the materials that fit these criteria and are commonly used are:

Though rare, you can sometimes find Hydraulic Cartridge Valves made from plastic depending on the specifications of your application. As you already know, leak-free valves require precise machining of the material.

To improve the durability of your valve, your manufacturer may opt for surface finishing the material. Such finishes like powder coat, polish and chrome plating extend its service life and improve performance.

Installing A Hydraulic Cartridge Valve

Installing Hydraulic Cartridge Valves is quite an easy task. This is because you will simply be required to place them or screw them into the manifold block of your hydraulic system, simple.

However, you need to be careful while fastening them. Ensure their seals and O-rings are well positioned to prevent any form of leakages during operations.

Hydraulic Cartridge Valves Vs Normal Valves

We can take a one-on-one comparison approach of certain aspects for this comparison. Keep in mind that their applications are almost similar being that they are both valves.

· Installing And Maintaining

Hydraulic Cartridge Valves: you can simply install them by placing them on a manifold. You can also replace them easily with quicker maintenance procedures compared to traditional valves.

Traditional Valves: these valves are usually larger meaning you will take more time to install and maintain them. Due to their complex design, you are more like to disassemble significant parts of your hydraulic system while replacing them.

· Use Of Space

Hydraulic Cartridge Valve: they are usually compact and therefore save you on a lot of space. You can utilize them best in applications that have space constraints.

Traditional Valves: due to their size and complex design, you will be required to allocate them more space. Simply put, you cannot use them if your application has premium space requirements.

· Modularity

Hydraulic Cartridge Valves: the high modularity of these valves gives you a chance to replace them without altering your hydraulic system. This means that you can customize your hydraulic system without so much hustle.

Traditional Valves: we normally consider these valves as part of the complex hydraulic system during assembly. Yes, you can always replace them but they will take more of your time and labor as opposed to cartridge valves.

· Size And Design

Hydraulic Cartridge Valves: they are usually very compact and self-contained valves that you can easily insert into your hydraulic system manifold. Their modular and small design gives you an easy time during their installation and maintenance.

Traditional Valves: they are normally very big and come in complex designs compared to the hydraulic cartridge valves. Their complexity comes from the fact that they have very many parts that have been assembled.

· Cost

Hydraulic Cartridge Valves: you will spend more on this valve compared to the traditional valves. The upside of this though is that their maintenance and modularity greatly reduce the eventual cost due to reduced downtime.

Traditional Valves: their initial cost may be cheaper than the hydraulic cartridge valve. However, you will eventually spend more while maintaining and replacing them besides the high downtime they will have.

How Spool Hydraulic Cartridge Valves Compare To Poppet Hydraulic Cartridge Valves

The best way we can compare these two valves is through their sealing mechanism. Let’s look at them individually in detail:

· Spool Type Hydraulic Cartridge Valve

The sealing in this valve is carried out using the spool’s cylindrical surface. The surface creates a gap while sealing meaning you will have some leakages on this valve.

You will notice the leakages increasing with operation time. Reason? The gap will keep on expanding as the cylindrical surface wears over time reducing its service life.

However, the upside of it all is that you can make it work with zero coverage or even a zero-to-zero pre-opening. If the application requires different strokes, the valves many pre-grooves can easily achieve that.

· Poppet Type Hydraulic Cartridge Valve

The sealing in this valve is aided by the line contact seal. This means that your valve is leak-free and does wear out easily giving it an extended service life.

One of the benefits you can get from this valve is its very rapid and sensitive shift responses. The downside is that it has operational vibrations that produce a buzzing sound.

Applications Of Hydraulic Cartridge Valves

The various applications you will find for these valves include:

- Hydraulic pressure relief systems

- Industrial hydraulic systems

- Directional control assemblies

- Hydraulic testing equipment

At Target Hydraulics, we help get high-quality and reliable hydraulic valve systems for your unique applications. Whether you want standard or custom designs, Target Hydraulics is your perfect partner.

More Resources:

Hydraulic System Parts – Source: TARGET HYDRAULICS

Hydraulic Valve – Source: IQS Directory

Types of Hydraulic Systems – Source: TARGET HYDRAULICS