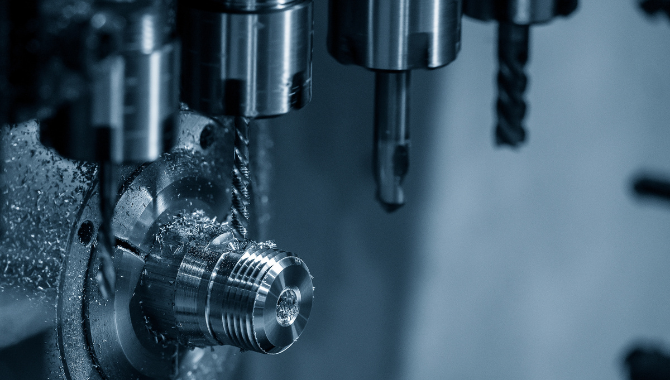

Screw machining is an accurate machining technique that effectively produces large quantities of intricate, small metal parts by using automatic screw machines. The devices cut bar stock using spinning cutters to create finely formed components for a variety of applications.

Screw Machining Additional Capabilities

Screw Machining Pro's Advantages

Automation: Automatic screw machines can operate with very little operator monitoring. Typically, all they require assistance with is setup and switchover.

Precision: The use of a guiding bushing and collet results in improved precision for manufactured items when compared to other types of lathes.

Efficiency: Utilizing several spindles also improves production efficiency.

Uniformity: Screw machining processes result in products that are identical from batch to batch and from piece to piece.

Size capacity: Turning is perfect for producing larger pieces that need careful attention to detail, as well as little parts that would be difficult to manufacture in any other way.

Screw Machining Process

Choice of Material

The first step in the process is to choose the right material for the item that you have in mind.

Turning

Using cutting screw machining tools, the outside diameter of the bar material is generally lowered to the desired size and shape as the initial operation.

Facing

The bar stock’s ends are faced to make sure they are parallel to the central axis and flat.

Drilling

Specific drills are used to drill holes into the workpiece.

Tapping

A tapping process is carried out if the part needs threads.

Milling

To add more characteristics to the part, like slots, flats, or other intricate geometries, milling processes are utilized.

Cross Drilling and Cross Tapping

In certain screw machining processes, holes and threads are made at an angle to the main axis.

Parting Off

After every machining operation is performed, a parting tool is used to remove the completed item from the leftover bar stock.

Quality Control

After completion, the parts are inspected to make sure they adhere to the required tolerances and quality standards.

Secondary Operations

Additional secondary operations like heat treatment, plating, or coating may be carried out based on the particular requirements of the part.

Utilizing Screw Machining in Industrial Settings

- Faucet components

- Pipe connectors

- Valves with precision and consistency

- Aircraft fittings

- Spacers

- Connectors

- Orthopedic implants

- Surgical tools

- Dental parts

- Connectors

- Terminals

- Other small parts used in electronic devices and systems

- Valves

- Fittings

- Connectors that require precision and reliability.

- Trigger mechanisms

- Firing pins

- Other small parts, often involve screw machining for efficiency and precision.

- Valves

- Couplings

- Fittings that are crucial for regulating the flow of liquids and gases.

- Bushings

- Connectors

- Fasteners

- Fittings

- Fasteners

- Bolts

- Screws

- And other hardware components

- Shafts

- Bushings

- Spacers

- Studs used in machinery and equipment.

Suitable Materials for Screw Machining

- 12L14

- This leaded steel has a nice surface polish and is simple to process.

- 303

- Because of its superior machinability, screw milling is a common use for this grade of stainless steel.

- 4140

- Screw machining makes extensive use of this alloy steel because of its strength and endurance, which make it highly versatile.

- 360-Grade Free-Cutting Brass

- It’s well known that brass is very machinable and corrosion-resistant.

- This particular aluminium alloy is commonly used in screw milling due to its superior machinability and lightweight nature.

- Copper C110 (ETP)

- Pure copper is utilized in screw machining when electrical conductivity is required.

- Delrin (acetal)

- a thermoplastic with excellent machinability, low friction, and wear resistance.

- Grade 2 Titanium

- Although it can be difficult to mill titanium in general, Grade 2 titanium can be machined more easily.

- C36000 (Free-Cutting) Bronze

- When corrosion and wear resistance are required, screw machining applications employ bronze alloys containing lead additions.

- Inconel 718

- The exceptional strength and resistance to corrosion of this nickel-chromium alloy are well recognized.

Screw Machining Finishes

- To provide a uniform and smooth surface, the machined object goes through a grinding operation in this process.

- Abrasive materials are used during polishing to produce a bright, smooth surface.

- Certain components may go through electroplating after machining to acquire a particular finish.

- Free iron is eliminated from stainless steel component surfaces using a chemical process called passivation.

- An even look can be achieved by tumble-testing parts using an abrasive medium to get rid of burrs and sharp edges.

- The process of burnishing is exerting pressure with a firm, smooth instrument to smooth and harden a part’s surface.

Automatic lathes and screw machines are commonly used in screw machining. To create the desired shape and characteristics, these machines spin the workpiece while cutting instruments remove material. The procedure may be mechanized for large-scale production and is very effective.

Although highly effective in large-scale production, screw machining may not be the most cost-effective option for prototyping due to setup and tooling costs.

Single-spindle screw machines are appropriate for short production runs because they only have one cutting tool and only process one part at a time.

Indeed, screw machining is a good option for applications requiring a high degree of precision since it can achieve tight tolerances.

The part’s complexity, material choice, production volume, tolerances, and setup expenses are some of the factors that affect the price. Unique features and improved precision could raise the total cost.

A finished product may require secondary operations like threading, knurling, or further machining, depending on the part specifications.

CNC machines are controlled by a computer and are used for screw machining.

For your screw machining needs, Just contact KDMFAB.

And request screw machining PDF for more information