In the steel extrusion manufacturing process, molten steel is forced through a die that has a predetermined shape to create long, continuous shapes with a consistent cross-sectional area. Complex profiles, tubes, and other specialized steel components are frequently made using this procedure.

Steel Extrusion: Process Types

In the process of direct extrusion, sometimes referred to as forward extrusion, a ram or screw is used to force the heated steel billet through a die and into the appropriate shape.

In indirect extrusion, the billet stays stationary while the die and container move. The billet is contained in the container, and the die is pushed through the stationary metal to form the required shape.

Using a pressurized fluid—typically water or oil—to push the billet through the die is known as hydrostatic extrusion. Extruding complex forms is a common application for this method, which can yield a more consistent material flow.

As the name implies, cold extrusion occurs at or close to room temperature. By using this method, extra heat treatments are not necessary to produce steel products with a high degree of precision and surface polish.

In friction extrusion, the billet rotates as it is compressed against the die. When the billet and die to rub against one another, the material flows through the die and takes on its shape.

Hollow shapes are frequently produced using piercing extrusion. The billet is first hollowed out by inserting a piercing mandrel, and it is then extruded through the die to take on its final shape.

Steel Extrusion Process Work

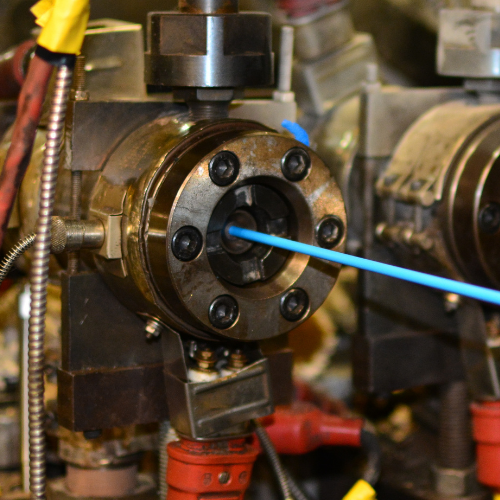

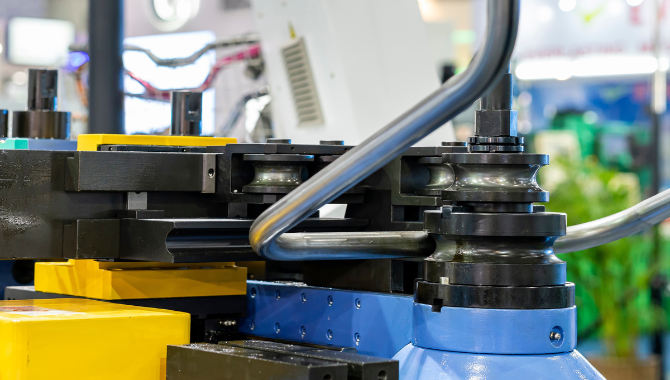

In a preheating furnace, solid steel billets are fed to start the operation. A hydraulic press or an extrusion press is used to drive the softened steel through a die after it has reached the necessary temperature. The steel emerges from the die with the desired shape, forming a continuous length with the required profile.

Steel Extrusion: Advantages

Complex Shapes: The creation of complex, personalized shapes is made possible by steel extrusion.

Cost-Effective: Making parts with little waste can be done at a reasonable cost with this technique.

High Strength: The strength and structural integrity of extruded steel components are frequently rather high.

Consistency: The procedure guarantees that the cross-sectional dimensions are consistent.

Steel Extrusion: Limitations

Limitations on Size: It could be difficult to extrude very huge or heavy profiles.

Limitations of the Material: The extrudability of some steel alloys may be restricted.

Cost of Tooling: For complex profiles, the initial tooling costs may be somewhat significant.

Industries Commonly Use Steel Extrusion

- Beams

- Columns

- and other elements used in building frames

- Structural parts for vehicles

- Chassis and frames

- Ships

- Trains

- and other transportation systems.

- Power plants

- Structures

- Frames, and other parts.

- Furniture

- Appliances

- and various household items.

- Bridge construction and other infrastructure projects use steel extrusion

- Steel extruded components may be used in electronics equipment and gadgets to provide structural support.

- Components for aircraft and spacecraft.

- Pipelines

- Supports

- and structural components found in machinery for exploration and extraction.

Material Types of Steel that Can Be Used in Extrusion

For extrusion, this is the most used kind of steel. Good strength and formability are provided, and it is reasonably priced.

Chromium, molybdenum, nickel, or vanadium are some of the elements that make up alloy steels, which also contain carbon and iron.

Due to its reputation for being resistant to corrosion, stainless steel can be used in corrosive conditions for extrusion applications. Stainless steel in common grades include 304 and 316.

Tool steels are robust, wear-resistant, and have a high hardness, making them ideal for tooling applications.

Tool steel that is appropriate for high-speed cutting processes is called HSS.

Bearing steels may be utilized in applications where extruded items must have exceptional dimensional precision and surface polish.

Microalloyed steels can be made stronger and more resilient by adding trace amounts of alloying elements like titanium, vanadium, or niobium.

It is true that steel extrusions can be finished with several techniques including painting, plating, anodizing, or powder coating to improve their appearance and offer more corrosion resistance.

Compared to other production processes, steel extrusion can have a comparatively low environmental impact since it frequently produces little material waste and allows for the recycling of extruded pieces.

Dimension checks, visual inspections, and testing for mechanical qualities are some of the quality control procedures used both before and after the extrusion process.

Yes, the ability to create unique forms and profiles that meet precise design specifications is one of the major benefits of steel extrusion.