With so many different sizes and complex structures, there are several types of electrical panels that are suitable for various needs.

Meanwhile, these panels work as the brain of electricity and understand the power level needed for certain locations. So. Here are some of the best types of electrical panels:

Types of Electrical Panels

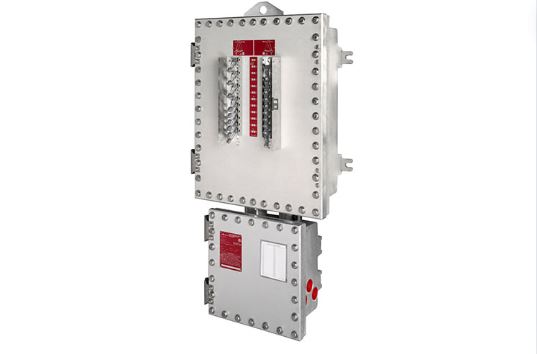

Main Lug Panel

The main lug panels usually don’t have a main breaker switch in them. Likewise, you must have some external main breaker panel to provide energy to it. In that case, it is mostly used as a subpanel in different situations if the main electrical panel is installed somewhere far away.

Meanwhile, they are simply connected to devices such as lugs. The lug simply delivers the power to the building from various circuits.

However, they consist of multiple types of configuration, which depend on the main electrical panel designs. At the same time, they are rated for a certain amount of amperages usually used when the code or design is different from the main panel’s mechanism.

Meanwhile, they are used as subpanels which connect the garage or workshop to the main circuit. Main lug panels are useful in industries that handle multiple-point distribution.

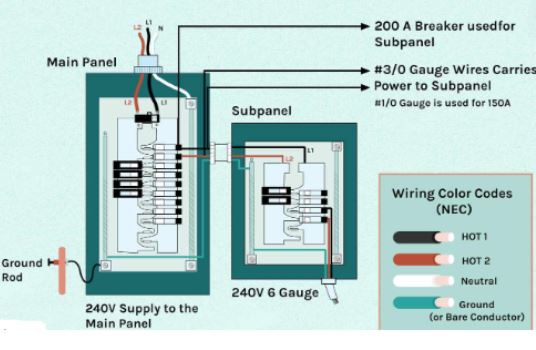

Subpanel

Secondly, subpanels are connected to the main electrical panels, and their duty is to provide power to certain areas. While being a secondary electrical panel, they are usually used to provide electricity to garages, parking or any small area. Meanwhile, they are mostly used when there is no space left in the main electrical enclosure to give power to an area.

You can also call it a smaller version of the main electrical panel, but it still works on the power of the main electrical panel. Main panel with the 240V circuit breaker and double pole to provide power to subpanels. However, the main panels are usually divided into further branches, each for a different subpanel.

Moreover, you need subpanels for their secure use because even if you have a huge main panel, it still lacks safety. Additionally, subpanels divide the power evenly for more smooth efficiency.

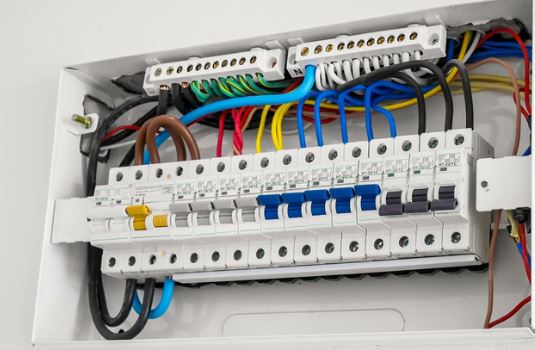

Fuse Box

If you were born in the nineties, you must have seen these fuse boxes in your houses or somewhere else. Meanwhile, they were so popular back in the day, but not anymore.

Fuse boxes usually have two fuses, which melt down in case of high voltage or heat up and protect the electrical systems. When we compare it with other breakers, it is less useful as we have to buy new ones after they melt down.

However, for an effective, safe use of a fuse box, it must have melting components in it. Also, the fusible sealed fuse components are usually present on the glass fuse body. The fusing element in the fuse box is actually a thin strip of metal.

Meanwhile, when there is a high voltage passing through this strip, it breaks it and melts the fuse. That’s how it protects the whole electrical system from major problems.

Motor Control Center (MCC) Panels

The next type of electrical panel is the MCC (Motor Control Center) Panel. Likewise, they are mostly used by industries that have many motors. Meanwhile, their main duty is to control the energy provided to the electrical systems and motors. They are flexible enough to install a cubic switchboard while connecting it with other switchboards.

They usually work best for low-voltage three-phase alternating motors. Typically, they have a voltage ranging from 208V to 600V. Also, the medium voltage ranges from 2300V to 15000V, and there are certain vacuum contactors to handle the power.

The automotive industry has been using MCC electrical panels since the 1950s because they rely on heavy motors. Nowadays, these panels are everywhere in industries and for commercial use.

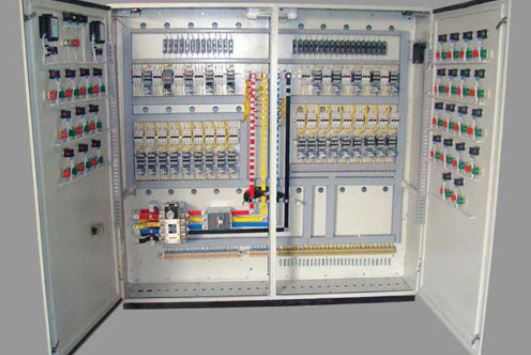

Power Control Center (PCC) Panels

Moving on, we have the Power Control Center Electrical Panels, which provide power to different subcircuits. For example, PCC panels produce heavy energy supplies like transformers, motors, and generators.

Their main power is to monitor, protect, and switch multiple devices such as feeders or breakers. You can also call them Main Switchboard.

Furthermore, the PPC electrical panels usually have multiple panels which can handle around 6300 amperes. There is a common control panel that is used to control and track various electrical efficiency levels.

Automatic Power Factor Control (APFC) Panels

Automated power factor control electrical panels are the most critical devices for managing highly reactive powers. They use different powerful capacitors to increase the efficiency of industries’ power supply.

Also, they control the heavy voltage changes in heavy-duty factories and industries with transformers or generators. While reducing energy usage, they carefully improve the equipment’s working abilities.

However, APFC panels are made to handle the highly reactive power of electrical systems. As you know, some of the systems need a reactive power supply to start working, so these panels help. So, APFC panels control this reactive power and supply the system with the amount they need to work smoothly.

Three-Phase Panel

On number six, we have the Three-Phase Electrical Panels mostly used by industries. For a constant power supply to factories according to their needs, these panels are the best choice. While they may have three or four wires, they effectively handle heavy machinery and multiple devices at a time. Also, for safe and secure use of power, these panels provide value to your needs.

At the same time, the three-phase electrical panels are suitable for both industrial and commercial usage. However, installing these panels is a little expensive compared to others because you need professional tools for that. While facing all the difficulties, they still work perfectly in hospitals, businesses and homes.

FPE Panels

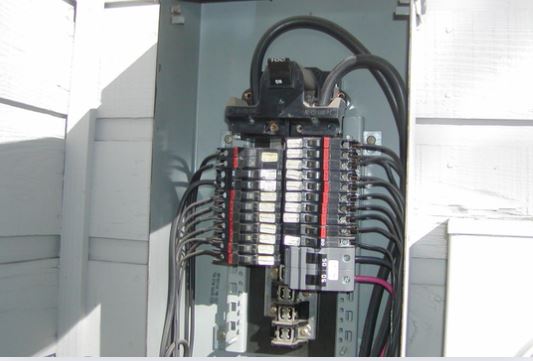

Finally, at the end of this list of best electrical panel types, we have FPE panels. However, the FPE electrical panels are the breaker boxes which are connected to the main electrical panels. Likewise, they have a separate circuit breaker to deliver electricity to different parts of your home using a strong wiring system. Meanwhile, they usually trip in case of high voltage and protect your electrical systems.

These panels keep your homes safe while preventing any chances of heating up in wires or catching fire.

Federal Pacific Electrical panels are simply the breaker boxes which are mostly used in residential areas. They usually have two types; most homes have a combination breaker/GFI.

Comparison of Different Types of Electrical Panels

| Type | Description | Use |

| Main Lug Panel | Lacks main breaker, supplies power to other circuits | Residential/Commercial (Subpanels) |

| Subpanel | Expands circuits in a building | Residential/Commercial (Specific Areas) |

| Fuse Box (Outdated) | Uses fuses instead of breakers (not recommended) | Older Buildings |

| Motor Control Center (MCC) Panel | Controls and protects electric motors | Industrial Settings |

| Power Control Center (PCC) Panel | Distributes power to multiple sub-circuits | Industrial Settings |

| Automatic Power Factor Control (APFC) Panel | Improves power factor (capacitors) | Industrial (Motors & Transformers) |

| Three-Phase Panel | Distributes three-phase power | Industrial (Three-Phase Equipment) |

| FPE Panel | Provides reliable power for critical systems | Specialized Applications |

How to Choose the Right Electrical Panel?

A strong and effective electrical system is needed for all buildings or industries. In that case, choosing a perfect electrical panel is very important. However, whenever you are going to buy some electrical panels, you should understand the following factors:

How Much Power You Need?

Firstly, consider the power need because choosing panels which cannot handle the heavy voltage will waste your money.

Likewise, understand the amount of power for various needs like industry or use in houses. It is better for you to plan everything before investing a lot of money in electrical systems which don’t even suit your requirements.

Perfect Planning is betterthan Wasting Time and Money

You need to plan every single step you take in your electrical power supply system choice. Because it is a complex thing to handle, in case of an accident, you can lose many things. For a secure future, you always choose the best for your family or workers in factories.

How Many Circuits Will Be Enough?

For better efficiency in electrical panels, you should choose perfect circuits and decide how many you want. For example, choose the number that fits your needs and don’t overload the electrical system.

Safe and Secure Electrical System Should Be a Priority

Don’t choose some cheap third-class quality electrical panels just to save a few pennies because electricity is a sensitive thing to handle. A little mistake can lead you to the worst shock of your life. Always go for the best quality in the market whenever choosing electrical panels for homes or industries.

Final Thoughts

In the end, a good electrical panel gives you peace of mind. Meanwhile, they are vital components of electrical systems. They are the best solutions for handling a safe power supply to your homes and industries. So, choose wisely and choose the best electrical panel.

Related resources:

Electrical Panel Vs Fuse Box – Source: KDM