A weatherproof junction box is necessary to protect the wires and connections both indoors and outdoors. This safe solution for your electrical systems is enclosed like a protected fortress. Let’s dive deep into the junction box and its uses.

What is a Junction Box?

The box allows for your cables to be joined together securely with the electrical systems.Alternatively called termination boxes or conduit cases, they encase the full cable system for excellent safety.

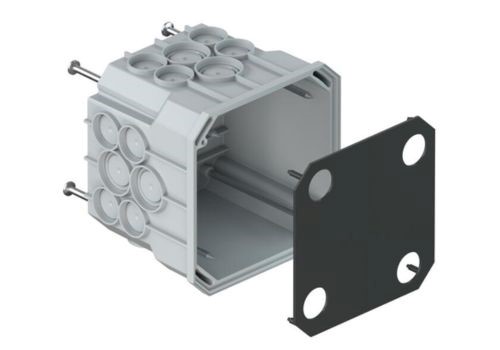

In most cases, these small electrical enclosure systems consist of a cover, an enclosure and conduits where cables may enter and exit.

You will need wire knockouts. Typically, these electrical junction boxes are surface mounted and are either housed on walls, ceilings, or floors respectively. It is used with the portable generators to operate more than one device.

What are Junction Boxes for?

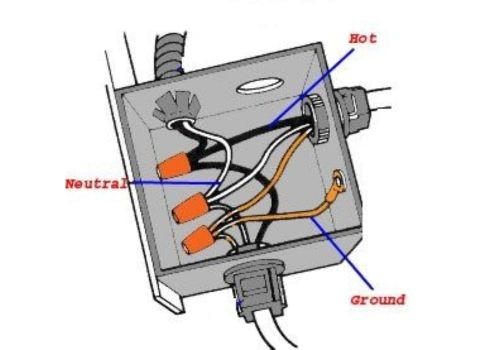

Junction boxes are designed to contain wires such as neutral (white), hot (black), and grounding (green or copper). They also come with random cables of different colors (which can be used for lighting or something else).

Enclosed Romex wires are then routed to main electrical panels or subpanels connected to junction boxes. Romex wire is a nonmetallic wiring which is used in the majority of residential branch circuit applications.

This junction box connects all cables from various distribution systems through Romex wires. All the cables used in these boxes and electrical systems are the same size.

How does Junction Box Work?

Like the name suggests, they work like a junction. That is, when you take one power source and supply it through the junction box, which divides the power into further branches.

But you should never forget that electricity was never your best friend, so be careful with it. After the power is supplied to the systems and divided into many wires, make sure to connect the correct wires using color labeling.

However, you can easily use wire nuts to protect your stripped and connected wires for a more effective workflow. So, following the steps correctly, you will see that the junction box is working fine. It would help if you double-checked that everything is working according to the plan and that no exposed wire is left.

What are The Main Types of Junction boxes?

The junction boxes come in various sizes and materials to the functions and used. Meanwhile, various types of materials are used in the manufacturing process of junction boxes.

Some are PVC, metal junction boxes, and plastic junction boxes. For metallic junction boxes, the most common materials include steel and aluminum.

Because of its solid nature, it lasts longer than plastic junction boxes. Moreover, it depends on the features you need from a junction box, so they are designed accordingly.

Here are some of the most excellent varieties of electrical junction boxes (EJBs):

1. Standard Junction Box (or Electrical Box)

These are the most basic designs of junction boxes. Also known as electrical boxes, these systems are suitable for most homes electrical installations.

Meanwhile, this junction box protects the elements from tampering or unwanted short circuits. Usually, they are made of plastic or metals of various sizes and contain different wiring arrangements. For adequate power flow all over the electrical systems, you need a standard junction box for safety.

2. Octagon Junction Box

Secondly, as the name tells the story, octagonal junction boxes are designed in octagon shapes. This octagon design aims to fit a more significant number of wires and connections easily. Meanwhile, they are popular when you need to use junction boxes in compact spaces like cramped corners or cramped rooms in both residential and business places.

If you want to install these octagonal junction boxes, first, you need to be careful and shut off the circuit’s electricity. You can use these boxes anywhere you want, such as walls or ceilings, with the help of wood screws.

On the other hand, when you are choosing a junction box, make sure it can easily carry the weight of fixtures. After installing the box, you can unwrap all the wires inside the box. When you have finished fixing all the wires to the subpanels, you can turn on the power back and double-check the installation.

3. Round Junction Box

Moving on, we have the round junction boxes, which are a circular form of a box. When you don’t have much space to install the junction boxes, you can choose round junction boxes.

However, it comes in various sizes, and you can easily connect it with electrical panels. Moreover, they are mostly made of plastic or metal but are perfect for safety.

They are easy to install anywhere you prefer, but we suggest you use them when you don’t have much space.

4. Square Junction Box

Square junction boxes usually look like regular junction boxes, but they are not rectangular in shape, as the name suggests. So, users can use this type of square junction box anywhere in the corners or on the walls.

Meanwhile, they are primarily used in residential or business places, and you can even prefer them for their aesthetic designs.

Square junction box is a and durable electrical box. Also, they are easy to install anywhere on the wall or ceiling.

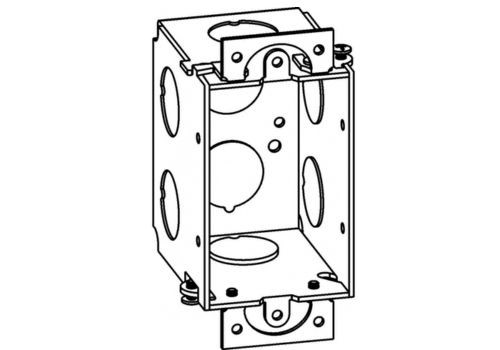

5. Rectangular Junction Box

Next, we have the rectangular junction boxes, which are widely used in many residential places these days and business locations. They can easily fit wires inside the box for perfect connections and a secure working experience.

They consist of many sizes according to what you need for any space. This junction box is mainly made from steel or plastic for work efficiency and durability. It would help to have a good rectangle junction box to provide precise power throughout your electrical panels.

6. Weatherproof Junction Box

You don’t need to worry about dealing with harsh conditions and rainy weather; choose weatherproof junction boxes instead. As you know, it’s unsafe when water comes into contact with electricity because it can destroy the system or cause more damage.

So, to solve this problem, you would prefer to install a weatherproof electrical junction box in outdoor areas. However, they are mostly made from steel to avoid corrosion and long-lasting ability. Meanwhile, people use it outdoors for lighting or irrigation.

7. Floor Box

You can choose this type when you need a junction box to fit inside your floor. Meanwhile, floor junction boxes are primarily used in commercial areas like Malls for safety and stability. People prefer this type of junction box to avoid messy, big-sized boxes on their walls or ceilings.

There are also many types of floor junction boxes. Some are made from metal, and some from plastic. Choose what best suits your needs because this type lasts longer.

However, when installing this type of junction box, make sure there are no floor joists or utilities under your floor so you don’t cut them accidentally, which can become a bigger problem. Also, when you find a perfect spot to install this junction box, tighten the adjustments and carefully cover all the open areas so no one can easily reach them.

8. Ceiling Box

Next on the list of best junction boxes is the ceiling. This type of junction is designed to be mounted to the ceiling, so you don’t have to look at your walls and the space in the ceiling to install them.

In most residential areas, some businesses prefer this type of junction box. Also, you can choose the metallic or plastceiling junction boxes box according to your requirements.

First, you need to make a perfect-sized hole inside the ceiling where this junction box can easily fit. Then, fix this junction box to an extendable and rotatable brace, which will help you fit it and provide durability.

9. Exterior Junction Box

If you need a junction box that can deal with harsh weather conditions and is corrosion-resistant, choose an exterior Junction box. They are made from stainless steel, which naturally resists corrosion and can handle moisture conditions.

Sometimes, people want their junction boxes to fit outside their houses or rooms so that you can install them. Likewise, it provides safety and is environmentally friendly. They are essential in electrical systems; you can easily install them outside the building.

10. Plastic Junction Box

As you know, several materials are used to manufacture junction boxes. So, when you need light material that doesn’t cost much, you can choose a plastic junction box. It is popular these days for its compact structure and durability.

Likewise, to ensure the safety of your electrical system, handle all the messy wires in an organized arrangement. Because of its lightweight, it is used in many industries.

You can drill the holes in the walls or install this junction box wherever you want. Then perfectly fix it and tighten the screws. Because of its lightweight, it lasts longer and doesn’t cause any trouble in case of unintentional breakdown.

11. Metal Junction Box

Suppose you need a strong box that can handle all the heavy lifting and organize your messy wiring; choose a metal junction box.

Because they are usually made of stainless steel, they can quickly deal with corrosion and harsh weather conditions. By using these boxes, you will not have headaches about rainy season problems. However, these junction boxes are usually more expensive than plastic ones because metals have high costs.

12. Surface-Mounted Junction Box

If you want your junction box to be behind an access panel or on the ceiling, you can use a surface-mounted junction box. Meanwhile, any minor, lightweight metal or plastic can make a perfect junction box for your buildings.

They are mostly preferred by many industries, including the food and packaging industries. Because they are environmentally friendly and provide safety, they are also popular in most residential places.

13. Flush-Mounted Junction Box

Whenever you want to install electrical appliances, you need a flush-mounted box. They connect the power points using wires to electrical panels.

Likewise, they are designed to be easily fixed on the walls. In particular, they are mostly used to install switches or sockets. They can be manufactured using both metal and plastic, according to your needs.

14. Gangable Junction Box

The Gangable means two or more boxes joining together to make a multi-gang box. Likewise, you can find these boxes easily, some with brackets and some without. However, they are mainly used for commercial and industrial purposes.

Generally, you can use this junction box when dealing with so many wires in one place. They work seamlessly for a long time and can be made from both materials.

15. Non-Gangable Junction Box

This type of junction box is usually used in residential and factory settings. It is mainly used when passing wires through some surfaces because it provides safety. Likewise, Nonchangeable junction boxes are made solid to last long without causing unintentional harm to the electrical systems.

How to Choose the Right Type of Electrical Junction Box?

Before you buy a new Junction Box for your office or house, you should always consider some factors. Moreover, those factors will help you decide which one to choose.

· Safety is Always First

First of all, you have to make sure the junction box you buy is safe. Likewise, switch off the main power before connecting any device to the main electrical panels. Sometimes, so much wiring inside the box creates a messy arrangement, which can increase the risk factor.

Meanwhile, cover all the unwrapped wires so nobody can accidentally touch them. While connecting the junction box, you can cut off the main power to check if it works properly.

· Number Of Terminals

Next, whenever you want to choose a junction box, it usually depends on the number of connections you need. In most cases, you will find junction boxes with about 3 to 6 terminals. Likewise, you can choose the one you need for your connections.

· Material of Junction Box

Several types of material, such as plastic or metallic, are used to build a perfect junction box. Metal junction boxes are mostly used because they are strong and can withstand corrosion or harsh weather.

· Size of Junction Box

Although junction boxes come in many sizes, the most common option is the 4-inch square design. It is popular because of its standard size. Also, the sizes of junction boxes used in residential areas usually differ from those used in heavy-working factories.

It depends on the number of wires it carries because a good junction box should easily arrange all your wiring inside its spaces.

· Rating of Junction Box

Manufacturers characterize the safety ratings of various junction boxes differently. It is a good idea to select a junction box that meets your application’s specifications.

· Technique of Wiring

In the end, you can decide which design to buy based on the number of connections you installed. However, Conduit junction boxes work best for conduit fittings. In case your wires are sheathed in metal, then go for metallic junction boxes.

Safety Ratings for Junction Boxes

It’s on the market, just like any other electrical equipment. Junction boxes also need to meet safety standards. These safeguards are in place to protect both your safety and the standard operating procedures for industrial safety.

The three primary junction box ratings and their respective meanings are as follows:

NEMA Ratings

The environmental ratings for junction boxes are determined by The National Electrical Manufacturers Association (NEMA). NEMA ratings range between 1 and 13. Each rating represent a certain degree or level of protection.

For example, the NEMA Type 1 Junction box protects human contacts or objects. So, you will know you can use these junction boxes in case of water, dust, or oily situations. Moreover, the NEMA Type 1 Junction box protects the connections from corrosion and dust and is perfect for indoor usage.

IP Ratings

IP (Ingress Protection) ratings determine how well junction boxes can protect themselves against solid objects and water. The first number in the IP rating on enclosure indicates the protection level of solids. The higher the number, the safer the junction box.

On the other hand, the second digit in IP Ratings indicates how strong the junction box is against corrosion. For example, the IP Rating for dust protection and corrosion resistance is IP 65.

UL Ratings

The Underwriter Laboratories, or UL Ratings, organize the junction boxes based on safety level and quality. Meanwhile, the UL enclosure ratings start from 1 and end at 13, each rating for a certain level of protection. You need to understand all these ratings before you buy a junction box because they are not progressive. The higher scores usually equal a better level of security.

How to Install a Junction Box?

Have you chosen the type of junction box for your office, or are you now wondering how to install it? It? Don’t worry. First, be careful with electricity: it cuts off the power source.

· Indoor and Outdoor Installation Steps

Now let’s examine the detailed process for installing your junction box:

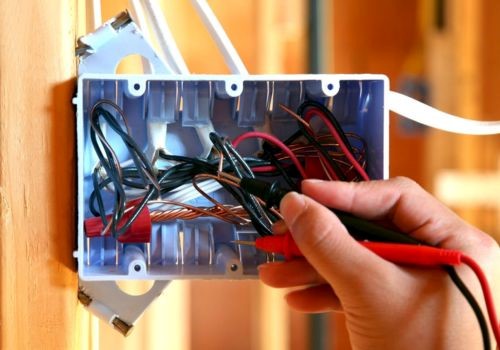

You can quickly check the current flow through your connected wire using any tester or voltmeter. There are two basic locations which a junction box can be installed: immediately after it leaves the house (whether on an outdoor wall or indoors). If you are going to install the junction box outside, use screws. In the indoors, you can use nails to mount on walls or ceilings.

· Handling Cables in Metal Junction Boxes

If your junction box is made of metal, you must strengthen it using cable clamps hung from outside the box.

Then, you will need to run your cables through the holes of the junction box into it (FIG. 2). Use a 1/2 inch Sharpie to indicate where the connectors poke through the clamp.

Once the cables exit the junction box, cut each cable about six inches from your first marking. Package Strip the wires together and insert them back into the junction box If the wires are made of metal, you should tighten clamps on both sides for securing the wires to reinforce their installation.

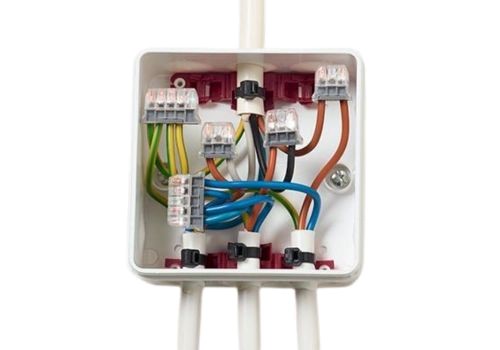

· Wiring and Securing Connections

You won’t have to use plastic junction boxes in the same way. With self-tightening clamps, the junction box ensures secure connections.

Make sure to gauge the wire before you continue, so you choose to use the proper size stripper. Hold the wire end by the stripper and check to see how much needs to be cut off. Once sorted out, strip the wires you are going to connect in the junction box (about an inch or so of conductor). Exercise caution to avoid damaging the cables.

Connect all of the wires using color coding. If this is a metallic junction box, the most accessible place to start would be with the ground wires. Also, you can use a pigtail to strengthen the grounding for the metal boxes. Using pliers will allow you to reinforce and tighten the wires considerably more tightly while joining them.

After connecting the ground wires, you can connect the neutral wire and add the love connections at the end. To make sure the connections are safe, you should label them. At the same time, you can use various types of good insulating tapes to cover the exposed wires. Then, neatly fold the connection to fit perfectly inside the junction box. Finally, after all the steps, you can close the junction box and start using it.

Conclusion

Finally, this was the whole story of junction boxes. Likewise, the junction box is essential for electrical connections for many reasons. So, you need to understand the ratings and features of various junction box types before selecting one.

More resources:

Terminal Box Vs Junction Box – Source: KDM

Junction Box Vs Pull Box – Source: KDM

The Different Types Of Electrical Boxes And How To Choose The Right One – Source: KDM

Top 20 Junction Box Manufacturers in USA, CHINA, and other countries in the World – Source: KDM