I know many people tend to confuse electrical terminal box and junction box.

Well, this guide will help you understand what these two essential accessories in electrical installations are. From definition, uses, installation, uses to features – we will explore every aspect of terminal box vs junction box.

Let’s dive right in:

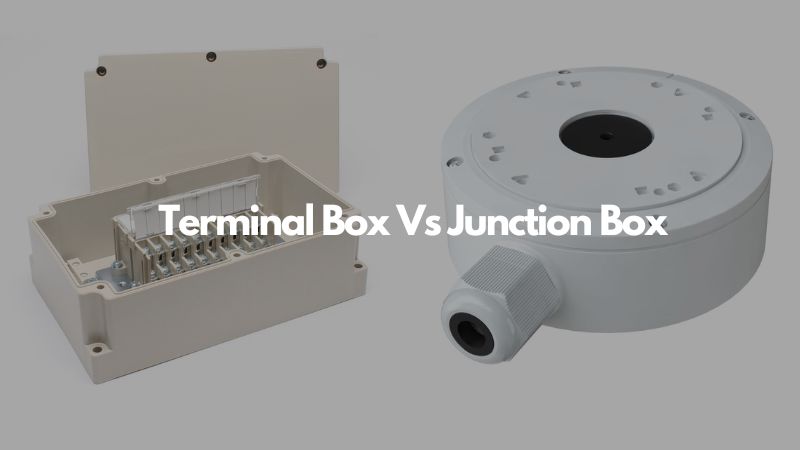

What Is A Terminal Box?

These are boxes that house insulated terminal blocks that are used in joining two or more wires. Their main application is in factories with the main purpose of having all wires secured and terminated.

What Is A Junction Box?

This is an enclosure that that accommodates electrical connections made from wires. They can either be made of Aluminum, Steel, Stainless Steel or a Polymer.

Their aim is to accord easy access to the wiring system during repairs or when alterations or additional conduits are needed. Furthermore, they protect the wires from extreme environmental conditions like corrosion or rain.

Terminal Box vs Junction Box: Pros And Cons

Let’s look at the advantages and disadvantages of these two essential accessories in electrical system.

Electrical Systems Terminal Box

Notable advantages we can look at include:

Relatively Affordable

This is their major advantage when we compare them with other boxes. This mainly because of the terminal blocks used in connection.

When you connect wires using a terminal block, more time is saved since it is not elaborate. It’s as easy you stripping a wire and just connecting it to the block.

Saves Space

Having multiple terminal boxes in your premise can save a load of space. This is due to the fact that a single box can contain numerous circuits.

Enhance Safety

Your components are kept safe they are grounded and isolated thus don’t interfere with each other. Additional safety is the test points they offer in the event of component failure in the circuit.

Simple Installation

You can use simple tools like a screwdriver to install basic terminal boxes. Troubleshooting and maintenance is also eased by quick disconnections and connections.

However, the main challenge with the terminal box is the possibility of wires loosening. Despite securing your connections properly, vibrations from the surrounding easily loosens them.

Additionally, people tend to install very big terminal boxes in anticipation of future additional connections. We recommend them in places where non-essential wiring is required to save on space.

Junction Box in Electrical Installations

We can have a look at the advantages:

i. They protect the electrical wiring connections from adverse environmental effects such as moisture

ii. They offer safety since they prevent unnecessary contact of live electrical wires with human beings

iii. The plastic type is very cheap and regularly used by contractors

iv. Due to the light weight of the plastic, it can be conveniently hang anywhere

v. Shortages are minimized in the connection. This is because of the non-conductivity of plastic hence no grounding needed.

On the other hand, the limitations are:

i. PVC used may be tough but plastic braces supporting them, chances of them falling is high

ii. Junction Boxes placed outdoors deteriorate faster than metal due to harsh weather conditions

iii. Plastic Junction Boxes are normally not compatible with conduits. Conduits are required in such a set hence making them unsuitable.

Installation Guidelines of Terminal Boxes vs Junction Box

When installing junction and terminal boxes, they must be fastened by screws on the back holes. The location should be easily accessible for technicians and placed in plain sight.

There are regulations to limit the number and length of cables in both boxes. Additionally, the consequences of not adhering are very obvious, electrical wires will end up overloaded.

When striping the cables to be joined, you must ensure that the cover goes back just far enough to be exposed. This will prevent any possible contact with adjacent connections and avert disaster.

Finally, ensure the boxes are properly earthed for the obvious reasons. The earth cables should correctly color-coded yellow/green to avoid confusion.

Material Composition in Terminal Box Compared to Junction Box

Junction boxes are majorly made of plastic or metal. For indoor use, the metal is normally steel with fiber glass or PVC covering the plastic boxes.

Aluminum Alloy is used for outdoor boxes due to its durability and resistance to extreme weather conditions.

Applications of Terminal Boxes Vs Junction Boxes Difference

For a junction box, its purposes are varied but we can argue that safety is its primary purpose. This is because it shields the live electrical connections from unwanted human interference.

Besides that, it protects the wires form external harsh conditions like moisture and dust. Finally, it assists in distributing power to multiple sources from a single source.

Terminal Boxes on the other hand provides a terminal test point that schematically assists during maintenance. The Terminal Blocks can also access control signals from various devices as input.

They are then sent as output signals to a control room for supervisory control and data acquisition. Such field devices include sensors, actuators or even command buttons.

Terminal Box Vs Junction Box Working Principle

Basically, the work of a junction Box is to use a single source of power and split it by housing the wire connections. This means that one power source into the box can power several electrical components in a place.

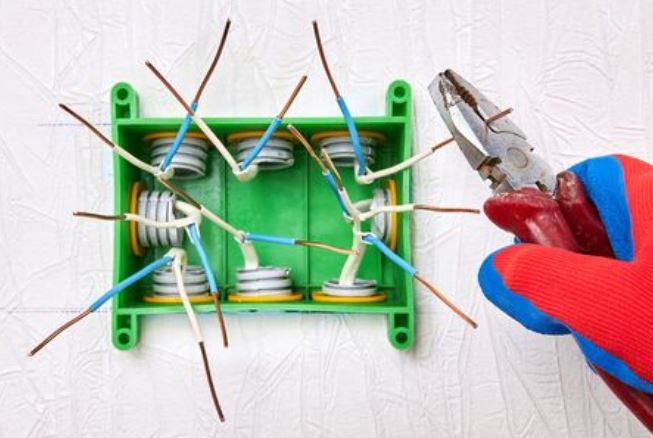

During installation, you will have to identify all the wires you want to use and strip them. You will then connect all wires having the same color then use different wire nuts to strengthen their position.

This completes your electrical circuit and all that remains is closing and powering it.

On the other hand, a Terminal Box houses insulated terminal blocks used in joining two or more wires. They mainly secure and terminate wires using long strips of individual block terminals.

Wiring Connections in Terminal Box compared to Junction Box

The wiring connection of a Junction is basic. We simply have a main power supply fed into with ends of the three terminals spliced.

We then splice all other component wires needed and join them to the main power source using color coding. For fastening, we use wire nuts that enhance their position and minimize movement.

In a Terminal Box, the wiring from the field instruments enter inside through the bottom. Inside it are strips of Terminal Blocks mounted on a mounting rail with end brackets limiting movement.

Every wire is spliced and a wire tag placed at each end. The tag on the wire entering the terminal bracket shows the terminal number it should be connected to.

The wire exiting the same terminal block shows the opposite end where the wire terminates.

Where to Install Terminal Box and Junction Box

As for Terminal Boxes mostly in factories, you can station them at all the duct run intersections. They are evenly spread across a factory to ease the connection between the control room and all field instruments.

On the other hand, you can have Junction Boxes placed anywhere it is needed in a building. This is so long as you do not violate any building regulations.

Features of Terminal Box compared to Junction Box

There are some distinct features that distinguish a junction box from a terminal box. Let’s take a look at the two:

Junction Box Features

i. An enclosure made of either metal or polymer

ii. Set of wire connectors

iii. Has entry and exit points on the enclosure surface

iv. Entry and exit points may have cable glands or just a hole

v. Comes in a variety of shapes and sizes depending on the intended purpose

vi. Used for specific connections with room for future expansion

Terminal Box Features

i. An enclosure made of either metal or fiber glass

ii. Contains a set of terminal blocks for connection

iii. Has entry and exit points on the enclosure surface

iv. Entry and exit points have cable glands

v. Comes in a variety of sizes but the shape is majorly square or rectangular

vi. Has no space for future expansion

Classification Criteria for Junction Box Vs Terminal Box

We have Junction Boxes in various forms and sizes. Let’s have look at the common ones:

Standard Rectangular

They are normally 2”-3” in size. They safeguard single light fixture wire switches and receptacles of regular power outlets.

These boxes are ‘gangable’ when your electrical set up is multifaceted. This simply means that you can link many boxes together using a detachable feature on their sides.

Round Pan

With a depth of about 0.5”-0.75”, they are normally shallow. They are most suitable for very light wall mounted or ceiling electrical fixtures.

Their size limits the wire connections to two or three. Needless to say, overstuffing them may heat up the ceiling fixtures with a possibility of Electrical Fire.

Standard Round And Octagon

They have more room for connections compared to round pan with a depth range of about 1.5”-3”. They are the best option for heavy lighting fixtures on ceilings and walls.

They are also the most preferred for old work applications. This is because of the fasteners they have that allows them to easily attach to the ceiling surfaces or walls.

Ceiling Fan Junction Box

As the name suggests, they are custom made for mounting ceiling fans. In as much as they are normally round, they are available in a variety of sizes and types.

As a precaution, never use octagonal or standard junction box fan for your ceiling installation. The rotating fan contains a dynamic loading that can’t be sustained by such boxes.

Standard Square Junction Box

They are also called 4-inch square junction boxes with a depth range of 1.25”-2.125”. With the square corners increasing the volume, multiple applications like connectors and conductors can be used.

Outdoor Junction Box

They are resistant to extreme weather and can be mounted on walls and decks outdoor. This is suitable if the setup of your outdoor electrical connections is complicated.

The plastic-type material is normally a PVC of high impact. For metal junction boxes, durable Aluminum is the way to go.

We can as well classify Terminal Structures but this is usually based on the devices they support and structure. Let’s delve the various types:

Determining Whether to Choose Terminal Box or Junction Box

You should a clear reason of the type of box you want to purchase and the reason why. The following factors can help you come to the right product between the two:

Enclosure Material

A major factor that will impact the material to be used for the boxes is the environment it will be in. Junction boxes are majorly made of Stainless Steel or Aluminum.

You easily place them either inside or outside a building because they can withstand weather. On the contrary, we can’t say the same for junction and terminal boxes made from PVC.

They can serve you well indoors for domestic or office use. But the exposure to outdoor extreme weather and indoor industrial chemicals takes a toll on them.

Volume or Size

One of the most crucial considerations you will take in is the dimension of the boxes. They must contain space big enough to accommodate all wires, terminal blocks or connectors used.

Additional fixtures like switches and receptacles should as well fit in well. The solution to it all is having your box with very good enclosure depth to increase their accommodation volume.

Connection Type

The mode of connecting cables on and inside your boxes is an important determinant. Collectors or cable clamps can be used in junction and terminal boxes besides knock-outs.

Clamps fasten sheathed non-metallic cables on the boxes preventing them from being pulled out. Alternatively, you can use knock-out holes on the boxes to attach conduits through them.

Rating System

Ratings from NEMA assist in knowing the location of your junction or terminal boxes. Such information includes whether they can operate in non-hazardous or hazardous places.

They also indicate if it fits the indoors or outdoors environments. All NEMA systems aim at shielding you from harmful contact with such equipment.

We also have the International Electrotechnical Commission (IEC) who have their electrical rating system called Ingress Protection (IP). It basically gives a description of the degree of protection the both boxes can give against access of foreign objects.

Conclusion

At KDMFAB, we will help you choose the right terminal box or junction box. Throughout the terminal box and junction box fabrication process, our team will help you get bespoke designs for your unique applications.

Contact us now for all your terminal or junction box needs.

More Resources:

Metal Junction Box – Source: KDM

Terminal Box – Source: KDM

Electrical Box – Source: Science Direct

Electrical Junction Box – Source: Wikipedia

Junction Box Vs Terminal Box – Source: EABEL

Junction Box Vs Pull Box – Source: KDM

The Different Types Of Electrical Boxes And How To Choose The Right One – Source: KDM