Probably, you are wondering why stainless steel material is popular in sheet metal fabrication.

It is due to the unique and extraordinary properties.

Whether you want to learn about history, types, grades, properties, manufacturing process or stainless steel surface treatments, you will find all the information here.

Let’s dive right in:

The Definition Of Stainless Steel

Stainless steel (SS) is a highly corrosion-resistant metal made by alloying iron and chromium alongside other elements. Notably, SS has at least 10.5% chromium.

Chromium is responsible for excellent corrosion resistance properties.

Polished Stainless Steel Sheet Metal

History of Stainless Steel

We can trace the history of stainless steel to over 100 years ago when Brearley invented rustless steel.

Although Brearley’s invention marked a significant milestone in stainless production manufacturing, many undocumented facts exist.

Let’s look at some critical development in the stainless steel history:

| Timeframe/Date | Person/Company Responsible | Key Milestone in Stainless Steel History |

| 1798 to 1912 | – |

|

| 1913 | Harry Brearley | He is accredited for inventing stainless steel with 12.8% chromium. |

| 1919 | Elwood Haynes | He got a patent for martensitic SS |

| 1919 to 1930 | Sheffield and other companies |

|

| 1929 | Williian Kroll | Discovered precipitation hardening stainless steel |

| 1930 | Avesta Ironworks | The first to produce duplex stainless steel |

| 1930 to 1935 |

– |

|

| 1950s to date |

– |

|

Even today, researchers are still trying to improve the existing stainless steel for better mechanical and physical properties.

More Resources:

- Stainless Steel History – Source: Azom

- Stainless Steel Metal – Source: Britannica

- Stainless Steel Metal Sculptures – Source: Aongking

Different Types of Stainless Steel

The 5 available SS types are:

- Austenitic stainless steel

- Ferritic stainless steel

- Martensitic

- Duplex (austenitic-ferritic)

- Precipitation

Let’s explore the stainless steel types in detail:

1. Austenitic Stainless Steel

Austenitic Stainless Steel Composition

Austenitic SS is a popular material in today’s metal fabrication industry. This is due to the unique features and properties such as:

- 16% to 26% chromium composition

- Nickel content is up to 35%

- Excellent corrosion resistance stainless steel type

- Not suitable for heat hardening

- It is tough and ductile

- Low carbon content

Due to its unique properties, austenitic stainless steel is common in the aerospace and food processing industries.

The most common grades are:

- Stainless steel 304, also called 18/8

- 316 stainless steel, and

- Stainless steel 321

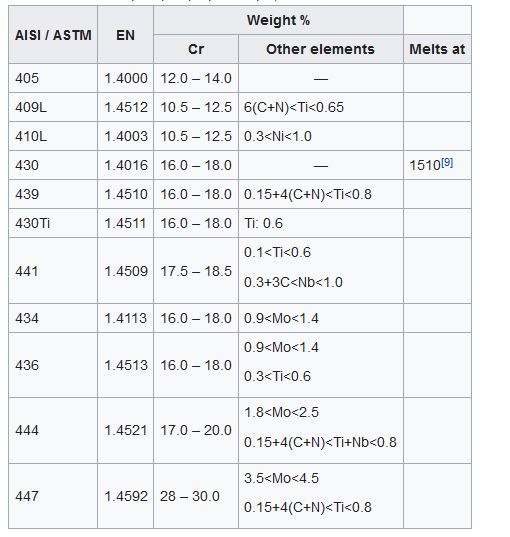

2. Ferritic Stainless Steel

Chemical Composition in Ferritic SS

Ferritic SS is yet another stainless steel material you may consider for sheet metal fabrication processes. Of course, it is due to unique properties such as:

- 2% carbon content (which is considerably low carbon content)

- Chromium content ranges from 10.5% to 27%

- Zero nickel content

- Not suitable for hardening by heat treatment

- Can be hardened by cold working thou moderately

- Austenitic SS has better corrosion resistance than Ferritic SS

You consider 409, 430, 439 and 441 Ferritic SS.

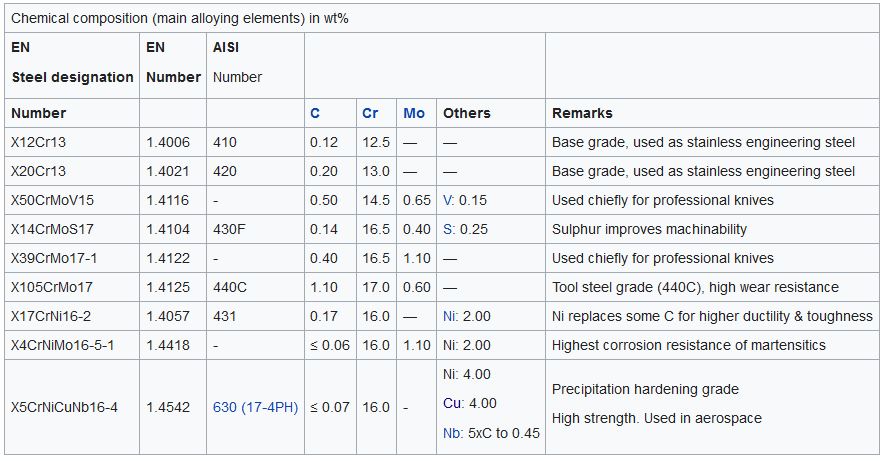

3. Martensitic Stainless Steel

Martensitic SS Chemical Composition

Unlike the other two stainless steel types, martensitic SS has the following unique properties and features:

- Chromium content ranges between 11.5% and 18%

- May contain nickel

- Carbon content is about 1.2%

- It can be hardened by heat treatment, unlike the Ferritic SS and austenitic SS

- Moderate corrosion resistance due to low chromium content

- They are magnetic

The most popular grade is the 400 series.

They are popular in turbines, cutlery and surgical instruments.

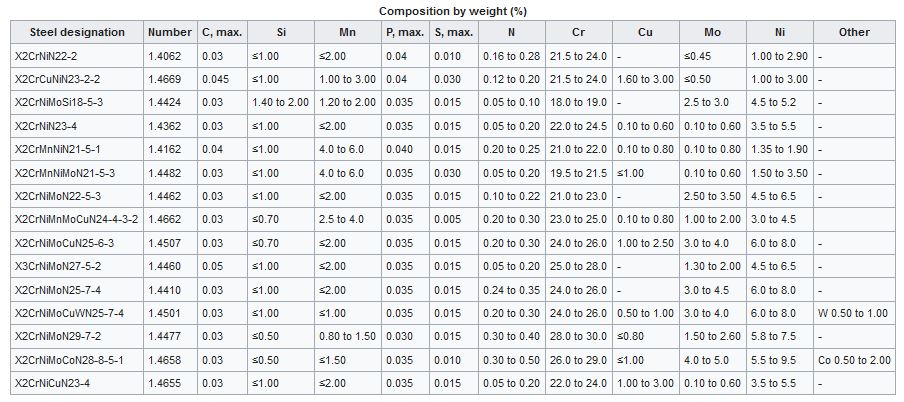

4. Duplex Stainless Steel

Duplex Stainless Steel Chemical Composition

Duplex stainless steel combines Ferritic SS and Austenitic SS in equal proportion. As a result, duplex SS is known for:

- 21% to 27% chromium content

- Nickel constitutes 1.35% to 8%

- Copper content is 0.05% to 5%

- 005% to 5% molybdenum

- Higher strength than austenitic SS and Ferritic SS

Owing to its superior properties, Duplex SS is suitable for chemical processing, chemical shipping containers and aircraft storage containers.

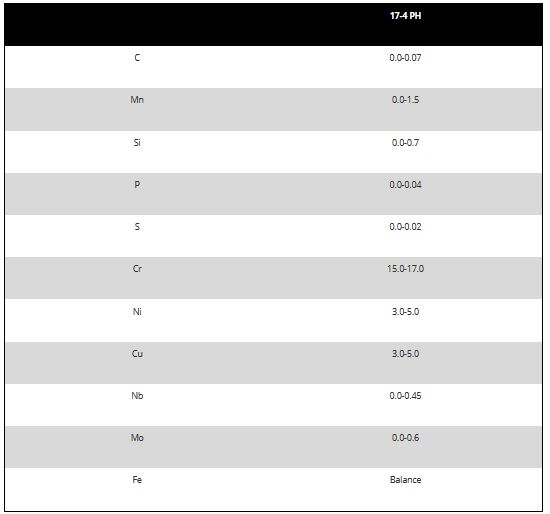

5. Precipitation Hardening Stainless Steel

Chemical Composition for Precipitation Hardening SS

Precipitation hardening SS is known for its high strength. Its fundamental properties include:

- 15% to 17.5% chromium content

- Nickel content is about 3% to 5%

- Aluminium, copper and niobium form less than 0.5% of the steel mass

- Hardening is possible by aging treatment

Precipitation hardening is suitable for valves, spindles, and shafts.

Now, let’s classify these stainless steel further by evaluating the various grades available.

More Resources:

Austenitic Stainless Steel – Source: Wikipedia

Types of Stainless Steel – Source: KDMFAB

Ferritic Stainless Steel – Source: Wikipedia

Martensitic Stainless Steel – Source: Science Direct

Duplex Stainless Steel – Source: Wikipedia

Precipitation Hardening SS – Source: Azom

Grades of Stainless Steel

Apart from focusing on different stainless steel types, exploring the various SS grades is essential. The information on various stainless steel grades will make choosing material for fabrication needs easier.

When it comes to SS grades, the focus is on material properties. These may include corrosion resistance, ductility or toughness.

Of course, this is not the case with the stainless steel families (SS types), where classification depends on the ratio of various elements.

This is due to the varying grading criteria for stainless steel material. Currently, the American Iron and Steel Institute grading system is widespread globally.

Let’s explore the SS grades:

| Stainless Steel Grade | Comments on properties, characteristics or applications |

| Austenitic Stainless Steel | |

| 201 |

|

| 202 |

|

| 205 |

|

| 301 |

|

| 302 |

|

| 303 |

|

| 304 |

|

| 304L |

|

| 305 |

|

| 308 |

|

| 309 |

|

| 310 |

|

| 314 |

|

| 316 |

|

| 316L |

|

| 317 |

|

| 321 |

|

| 330 |

|

| 347 |

|

| 348 |

|

| 384 |

|

| Austenitic – Ferritic Stainless Steel | |

| 329 |

|

| Martensitic Stainless Steel | |

| 403 |

|

| 409 |

|

| 410 |

|

| 414 |

|

| 416 |

|

| 420 |

|

| 422 |

|

| 431 |

|

| 440A, B and C |

|

| 501 |

|

| Ferritic Stainless Steel | |

| 405 |

|

| 429 |

|

| 430 |

|

| 434 |

|

| 436 |

|

| 442 |

|

| 446 |

|

At times, choosing a perfect SS grade for any application can be difficult.

A reason KDMFAB team is here to help you get the best stainless steel grade.

More Resources:

SAE Steel Grades – Source: Wikipedia

Grades of Stainless Steel – Source: Kloecknermetals

Stainless steel Grade -Source: Tuolianmetal

The thickness of Stainless Steel

Whenever we talk about stainless steel thickness, the first that comes is SS gauge sizes.

The SS gauge size refers to stainless steel sheet metal thickness. Usually, the thinner sheet metals have higher gauge numbers and vice versa.

Take a look at the example below:

| Stainless Steel Gauge | Stainless Steel Thickness | |

| Inches | Millimetres | |

| 1 | 0.2813 | 7.145 |

| 2 | 0.2656 | 6.746 |

| 3 | 0.2500 | 6.350 |

| 4 | 0.2344 | 5.954 |

| 5 | 0.2187 | 5.555 |

Typically, the stainless steel manufacturers will indicate the stainless steel thickness. Remember, knowing the thickness of stainless steel will help you determine:

- Suitable application for stainless steel sheet

- Choose the appropriate stainless steel sheet metal fabrication technique

Additionally, you may use various tools and equipment to determine the thickness of stainless steel. Some of these tools are:

- Vernier calliper

- Metal gauge chart

- Ultrasonic thickness measuring instruments

- Digital thickness meter

Well, there are many instruments for measuring stainless steel thickness. However, before using any instrument, ensure the calibration conforms to the set standards and regulations.

Sheet Metal Gauge Chart

More Resources:

Sheet Metal Gauge – Source: Custompartnet

Sheet Metal Gauge Chart – Source: Metal Supermarket

Properties of Stainless Steel

Let’s look at the leading stainless steel properties:

Mechanical Properties of Stainless Steel

SS properties vary depending on material grade. These mechanical properties include:

Mechanical Properties of Stainless Steel

Stainless Steel Yield Strength

When you are evaluating stainless steel yield strength, consider:

- High strength and low elongation

- Low strength and high elongation

On average, the yield strength for SS grades is:

- Austenitic stainless steel – 175 to 300 Mpa

- Ferritic stainless steel – 240 to 260 Mpa

- Duplex stainless steel – 450 Mpa

- Martensitic stainless steel – 350 Mpa

- Precipitation hardening stainless steel – 1000 Mpa

Stainless Steel Tensile Strength

Let’s look at the estimate tensile strength for various stainless steel grades:

- Austenitic SS – 600 Mpa

- Duplex SS – 700 Mpa

- Ferritic SS – 500 Mpa

- Martensitic SS – 650 Mpa

- Precipitation Hardening – 1100 Mpa

SS Resistance to Cryogenic Temperatures

Normally, austenitic stainless steel exhibit better performance at sub-zero temperatures. They are tough and maintain tensile strength.

It is not the case for precipitation hardening, Ferritic and martensitic grades. Their toughness reduces at cryogenic temperatures.

Stainless Steel Ductility

The ductility varies depending on the stainless steel grade.

Nearly all stainless steel grades have high elongation and work hardening rates. As a result, you can easily fabricate or deep-draw stainless steel.

For example, austenitic SS have 60 to 70% elongation.

Stainless Steel Hardness

Both precipitation hardening SS and martensitic SS can be hardened through heat treatment. On the other hand, Ferritic SS and austenitic SS are suitable for cold working.

Stainless Steel Physical Properties

In today’s sheet metal fabrication processes, stainless steel remains popular due to:

- Superior corrosion resistance is due to chromium forming a “self-healing” protective layer on the steel material.

- Resistance to high and low temperatures – Even when the temperatures fluctuate, stainless steel will maintain high strength and resist scaling.

- Aesthetic appeal – Stainless steel finishes offer one of the best metal surface finishes. Additionally, you can polish the SS surface mirror finish alongside other finishing operations.

- Low magnetic permeability – Austenitic SS grades are not magnetic. However, the cold working process may make this SS-grade magnetic. However, their magnetic properties are limited.

- Easy to machine and fabricate – you can easily cut, weld, bend, mill, drill or rivet stainless sheet metal easily

- Recyclability – You can recycle stainless steel material.

- Durable and long service lifespan – Stainless steel parts and components or parts will serve you for several years. Besides, they are also easy to clean and maintain.

Stainless Steel Electrical Properties

All stainless steel grades conduct both heat and electricity.

SS Electrical Properties

Although stainless steel is known for rust resistance properties, it can also conduct electricity. However, the electrical properties of stainless steel depend on the material grade.

Remember, stainless steel is an alloy of many elements as you will see later in this guide. Therefore, each element influences the electrical properties of stainless steel differently.

Take for instance:

- Chromium is known for its low electrical resistance. Therefore it implies, that it will allow for electrical conductivity. But remember, in most stainless steel, chromium forms about 10%. It implies, that even though chromium will allow for electrical conductivity in stainless steel, the degree will be quite low.

- Nickel and silver can also improve stainless steel’s electrical conductivity. For example, stainless steel plated with nickel is a perfect choice to transmit high current with minimal overheating.

Well, these two scenarios point to one thing – the electrical properties of stainless steel vary depending on the alloy composition.

SS Magnetic Properties

Not All stainless steel grades are magnetic. That is austenitic stainless steels are non-magnetic. This is mainly attributed to their unique crystal structure, which renders them nonmagnetic.

However, duplex, martensitic, and ferritic stainless steels are magnetic.

Furthermore, austenitic stainless steels have high levels of austenite. This gives thema unique crystal structure that renders these stainless steels non-magnetic.

Remember, work hardening some stainless steel grads may induce magnetic properties.

Chemical Properties of Stainless Steel

Stainless steel remains mysterious and unique due to its exceptional chemical properties. For instance, stainless steel offer:

- High oxidation resistance

- Best biologically inert features

- Resistance to organic compounds, acids, and bases

In short, stainless steel combines the best properties for any sheet metal fabrication process. However, before choosing any stainless steel grade, ensure you know its unique physical, mechanical and chemical properties.

Manufacturing Process of Stainless Steel

Manufacturing stainless steel is a systematic process that requires:

- Choosing suitable raw materials

- Adopting economical and effective SS manufacturing processes and technologies

In this section, you will learn all steps in the manufacturing process of stainless steel – let’s dive right in.

Manufacturing SS from Scrap Metal

Step 1: Get the Right Raw Materials for Stainless Steel Manufacturing

The main elements in stainless steel are:

- Iron alloys

- Additional elements such as nickel, chromium, carbon, etc

Therefore, you must get reliable sources for your raw materials.

Today, most stainless steel manufacturing uses recycled materials. This help reduce the raw material cost.

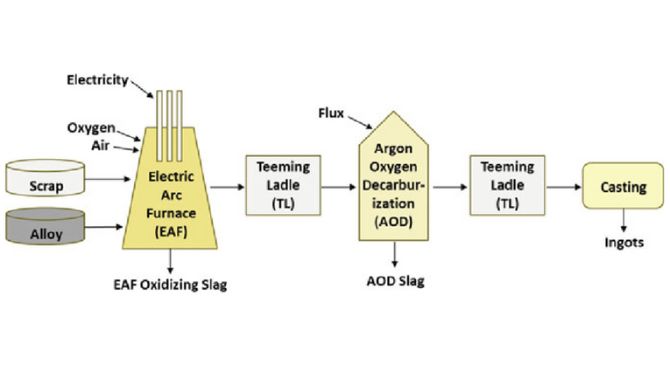

Step 2: Melting Raw Materials for Stainless Steel Manufacturing

You will melt all the raw materials in a furnace. For stainless steel manufacturing, an electric arc furnace is a viable option.

Melting raw materials can take between 8 to 12 hours.

Step 3: Removing Carbon Content in the Mixture

Depending on the carbon quantity expected in the stainless steel, you can use:

- Argon oxygen decarburization (AOD) converter

- Vacuum oxygen decarburization (VOD)

At this stage, you will use AOD to remove excess carbon. By injecting an oxygen-argon mixer, the AOD converter reduced carbon.

Alternatively, to produce stainless steel with low carbon content, you will use VOD.

Step 4: Adjust Stainless Steel Chemical Composition (Tuning)

Here, you will adjust the various chemical elements in stainless steel. Through tuning, you can make different stainless steel grades.

You will stir the mixture to remove unwanted alloying elements during the process. At the same time, the process improves consistency in stainless steel.

Remember, every alloying element is integral to the final stainless steel materials.

Take a look at this:

| Alloying Element in Stainless Steel | Alloying Element Function/Role |

| Carbon |

|

| Chromium |

|

| Nickel |

|

| Manganese |

|

| Copper |

|

| Silicone |

|

| Nitrogen |

|

In addition, stainless steel may contain manganese, molybdenum and tungsten. Of course, the quantity is always minimal.

As you can see, tuning is critical in stainless steel manufacturing. It ensures the alloying elements are in the right proportion.

Step 5: Forming Stainless Steel

You will cast molten stainless steel into different shapes, including:

- Billets

- Slabs

- Rods

- Tubes

- Blooms, etc.

Step 6: Hot Rolling Or Cold Rolling Stainless Steel

During hot rolling, you will heat the stainless steel products in step 5, then pass them through rollers. The heat rolling temperature should be above the recrystallization temperature.

During hot rolling, you will:

- Transform billets and blooms into stainless steel bars and wires

- Transform Slabs into stainless steel sheets, plates or strip

Cold rolling takes place below the recrystallization temperature. You can control the stainless steel part dimension.

The best part, cold rolling produces stainless steel sheet metals with the best surface finish.

Step 7: Annealing and Descaling Stainless Steel

Through annealing, you will soften, improve ductility and improve grain structure. Additionally, it helps remove stress from stainless steel material or parts.

After annealing, descaling help remove scales from the stainless steel surface.

Step 8: Cutting/Shaping Stainless Steel to Size

You can cut or shape stainless steel to a suitable size and shape. You will choose an appropriate tool and equipment.

For instance, you may use a CNC laser cutter, plasma cutter or brake bending machine. It will depend on the part you want to achieve.

Step 9: Apply a Suitable Surface Finish

There are many surface finishing you can apply on stainless steel sheets, rods or bars.

This may also include secondary operations such as grinding to remove impurities.

Step 10: Quality Control and Inspection

You should check stainless steel products or parts to ensure they conform to the standards. It may include determining thickness, examining the surface, and testing mechanical, physical and chemical properties.

In summary, this gives the stainless steel manufacturing process overview.

More Resources:

How SS is Made – Source: Marlinwire

Stainless Steel Manufacture – Source: Madehow

Stainless Steel Production – Source: Reliance Foundry

Surface Treatment of Stainless Steel

Stainless steel surfaces require surface treatment to improve desirable performance characteristics. The characteristics may include;

- Increasing surface hardness

- Improving corrosion resistance properties

- Improve aesthetic appearance or repair damaged sections

With the advancement in technology, there are many surface treatments of stainless steel surfaces. Let’s look at some popular options:

Stainless Steel Pickling

In the pickling process, you will use sulfuric or hydrochloric acid to remove impurities on the stainless steel surface. The impurities may include stainless steel rust, unwanted oxide layer or scale.

Stainless Steel Passivation

Passivation is perfect for polished stainless steel since it does not affect surface roughness.

In this SS treatment, nitric or citric acid eliminated free iron on the surface.

As a result, it enhances stainless steel corrosion properties.

Stainless Steel Electropolishing

Electropolishing removes a thin material layer from stainless steel. As a result, you will have an ultra-clean, shiny and smooth surface.

Electropolishing removes the thin outer skin from the stainless steel surface – it eliminates contaminants, oxide scales, burrs and heat tints.

Polishing Stainless Steel

You can polish stainless steel using alumina or chromium oxide.

Additionally, buffing will eliminate all possible surface imperfections on the stainless steel surface. Again, polishing and buffing stainless steel remove iron contamination.

Blasting Stainless Steel

Through blasting, you will remove iron contaminants and high-temperature oxides.

Brushing Stainless Steel

Brushing is an effective and cost-effective way to remove heat tint on stainless steel.

Water Jetting Stainless Steel

You can use water jetting to remove chemical deposits, grease and oils.

Apart from these techniques, other surface treatments of stainless steel processes are:

- Hot rolling

- Cold rolling

- Bright annealing

At KDMFAB, we will help you choose the best stainless steel surface treatment -contact is now.

More Resources:

Metal Surface Treatment – Source: KDMFAB

Sheet Metal Finishing – Source: KDMFAB

FAQ for Stainless Steel

1. Which Fields are Stainless Steel Used?

Nearly all industries use stainless steel. Stainless steel may form a section or the entire component.

Some common examples of stainless steel applications include:

- Home equipment and accessories – kitchen cabinets, kitchen sinks, shelves, jewelry, etc.

- Medical industry – surgical equipment, drug manufacturing machines, hemostats, surgical implants, temporary crowns, etc

- Building and construction industry – bridges, window profiles, door profiles, roofing structures, monuments, etc.

- Food and catering industry – cookware, kitchen accessories, grills, cutlery, etc

- Plumbing industry – making valves, pipes, fittings, pump parts, etc

- Automotive industry – vehicle body parts, springs, blades, cutting tools, ball bearings, fasteners, etc

- Aerospace industry – for making some aircraft parts and components

- Desalination plants – best for piping systems and tanks for seawater desalination

- Chemical industry – chemical storage tanks, valves, and piping systems are made from stainless steel.

- Power generation – stainless steel uses include turbine blades, furnaces, kilns, compensators, steam pipes, steam valves, heat exchanger systems, pressure tubes, electrical enclosures, reactor tanks, etc.

- Shipbuilding industry – Duplex stainless steel grade is a perfect choice for cargo tanks. Many ship body parts and accessories are made from stainless steel.

- Home appliances – dishwashing machines, microwave, blenders, refrigerator, washing machines, etc.

- Machinery – stainless steel is a perfect choice for parts directly contacting food.

- Military industry – artillery guns, missiles, fighter jet parts, armoured personal carrier parts, amongst others

- Waste treatment industry – waste treatment tanks, piping systems, and accessories, to mention a few

Therefore, stainless steel properties should be your guiding principle when choosing a material for any application.

2. How do You Maintain Stainless Steel?

Whether you have stainless steel sheets or finished parts, it is essential to adopt proper maintenance processes.

You can consider the following for all your stainless steel parts:

- Preventive cleaning – clean stainless steel surface to prevent stains from sticking or causing damage to the surface.

- Please don’t use any harsh chemicals on stainless steel since they may cause damage

- Where necessary, you can polish the stainless steel surface. You should ensure the process is economical.

- It would help if you avoided abrasive powders, bleaching agents or scrubbers to avoid damaging the stainless steel

- Whenever you are not using stainless steel is not in use -always cover the surface.

- Follow recommended stainless steel sheet installation processes.

Note: Stainless steel maintenance process may vary slightly depending on the part type. It will also depend on where you will use the stainless steel component.

3. What Is the Difference Between Stainless Steel and Carbon Steel?

Although the two steel types share many similarities, some distinguishing factors are:

| Stainless Steel | Carbon Steel |

|

|

4. How do you Calculate Stainless Steel Weight?

Calculating stainless steel weight may not be a straightforward process.

The easiest option is using an online calculator to calculate stainless steel weight. Some websites or companies offer such resources as:

However, if you are in a factory setup, there are many instruments you can use to measure stainless steel weight. Therefore, you don’t have to go through the stainless steel weight calculation process. The process can be tedious.

However, the fundamental aspects of calculating stainless steel weight entail the following:

- Stainless steel type

- Determine stainless steel density – the density varies depending on the chemical composition

- Know the stainless steel dimensions – these may include length, width and thickness. From here, you can calculate the volume

So basically, the stainless steel weight will be

It is important to note that these calculations (manually or from online calculators) give an estimation.

5. How do You Check the Current Prices of Stainless Steel?

It would be inaccurate to give a fixed price for stainless steel. However, we may quote stainless steel prices in different ways:

- Price per number of pieces

- Price per length

- Price per ton, etc.

The truth is, there are many factors determining the prices of stainless steel, such as:

- Stainless steel grade

- Nature of stainless steel – it can be stainless steel rod, sheet or tube

- Surface finish type

- Stainless steel quantity

- Supply and demand factors

- Production cost

- Manufacturer, etc.

So, how do you get an accurate stainless steel price – contact KDMFAB now for the best prices.

6. How Can You Clean Stainless Steel?

Cleaning stainless steel will increase its service lifespan. Additionally, it will help stainless material maintain esthetic value.

Let’s look at how to clean stainless steel:

Step 1: Know Stainless Steel Grade

Before cleaning stainless steel, you must know the stainless steel composition regarding various elements. It will help you choose the appropriate cleaning technique.

Step 2: Identify Stain/What you Want to Remove on Stainless Steel

Knowing the dirt or stain will help you adopt the best cleaning technique or procedure. Let’s look at some standard options:

| Dirt or contaminants to clean on stainless steel | Cleaning method and technique |

| Stainless steel routine cleaning |

|

| Removing fingerprints on the stainless steel surface |

|

| Cleaning stubborn stains |

|

| Lime deposits |

|

| Oil and grease |

|

| Corrosive stains or rust |

Note: You may consider the passivation process |

| Dark oxide on stainless steel |

|

| Scratches on a stainless steel surface |

Note: Don’t use the typical steel wool |

You can also consult the manufacturer for specific cleaning and maintenance procedures.

What is stainless steel 18-8?

18/8 Stainless Steel is composed of 18% chromium and 8% nickel.

What is stainless steel 18/10?

A high-end grade of stainless steel containing 18% chromium and 10% nickel.

What is stainless steel soap?

A piece of stainless steel, in the form of a soap bar or other hand-held shape

Conclusion

As you can see, stainless steel plays an integral role in the modern sheet metal fabrication industry.

Knowing the properties, features, benefits, applications, and maintenance procedures are fundamental when dealing with stainless steel materials.

At KDMFAB, we will help you choose the best stainless steel material and fabrication technique.

If you have any questions about stainless steel, contact us now.

More resources:

Here’s Everything to know about Stainless Steel Pipe Fabrication – Source: KDM