In the manufacturing space, every decision is an important one. From the choice of materials you go with to the very nature of your tools, everything is key. Part of these decisions you will make will have to do with the edges of your materials.

You might not know it, but edges play a critical role in determining overall material strength and quality. At the end of the day, the first part of your material that others will interact with is the edge. And if the edge is solid, then there’s a considerable chance that you’ll have a stable, durable product.

With that in mind, you also need to consider the types of edges that you’re working with. And today, bevels and chamfers have emerged as among the most prominent options available. This article will shed a little light on both options, allowing you to make a more informed decision.

Bevel vs Chamfer: Understanding The Edges

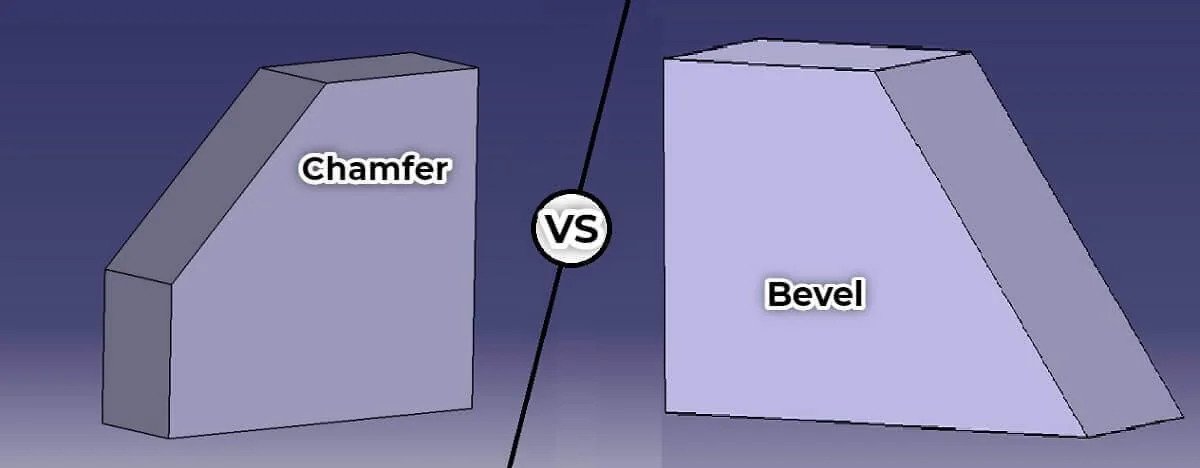

To get us started on the bevel vs chamfer edge comparison, let’s take a quick look at both edges and what they are, as well as how they work.

What Is Bevel?

To put it simply, the bevel functions as a sloped edge that doesn’t stand perpendicular to the surface of the object. Most product manufacturers tend to prefer these edges, with the bevel being an inclined edge that stands between two primary surfaces on a part.

In terms of angles, bevels usually operate at any angle that isn’t a right angle – so, as long as you’re not working with a 90-degree angle, you’re pretty much good to go. In most cases, these edges help with decorative uses, although they also serve considerable functionality purposes such as joining materials and offering wear resistance to materials.

Many of the products that you see today will feature a beveled edge. Whether it’s furniture pieces like mirrors and tables, a beveled edge can help to round things out, ensuring that the edges aren’t so sharp that they cut people or pose a safety hazard.

What Is Chamfering?

When you’re talking about a chamfered edge, it’s really simple – these edges have been symmetrically cut to fit different angles. Bevel vs chamfer vs beveled, Like the beveled edge, a chamfered edge was developed to provide a possible alternative to right angles and their generally monotonous look. Today, different fields, from woodworking to product engineering and more, make use of the chamfered edge.

Based on standards, chamfered edges’ most significant property is the angle at which they have been cut. In most cases, you have these edges being cut at 45 degrees, although it’s also quite common for you to have variations based on your design preferences and the needs of the operation itself.

You can engage a chamfer edge for several reasons – it helps with safety since the corners of the edge aren’t so sharp, it allows you to easily assemble and access your product, and it also provides a significant durability benefit as it cuts down on the risk of breakage.

Just as well, there is an aesthetic benefit of chamfering. You can add a chamfer edge to a piece of furniture, for instance, and help it to achieve a more refined and visually attractive look. Today, different materials can easily incorporate the chamfered edge – whether it’s plastic, wood, metal welding operations, or even stone. And with their ability to provide optimal edge protection, you can imagine why they have become exceptionally popular.

Bevel vs. Chamfer: Major Differences Between The Two

Now that we understand the answers to the questions “What is a beveled edge?” and “What is a chamfered edge?” let’s go over some of the prominent points of distinction between them.

To be fair, there are a lot of similarities here – in fact, some developers even claim that it is possible to use a beveled edge and a chamfered edge in place of each other. That said, if you’re really particular about product uniqueness, then you need to be aware of a few differences – such as:

The Reason For Their Designs

To start with, there are differences in broad design intent for both edges. For instance, bevel construction is mostly done to serve both aesthetic and functional purposes. With the angled cut, you get to enjoy significant aesthetic benefits, while also achieving protection for your edges and easier access to the product in question.

On the other hand, chamfering mostly helps to serve aesthetic functions. Manufacturers mostly use a wood chamfer to ensure that products are safe, preventing any sharp corners and providing a general ease of assembly overall.

The Characteristics Of The Angles

Next, let’s look at the angular dynamics of a bevel vs chamfer edge. For beveled edges, you can get different angles generally – your choice will mostly vary based on what you need for the design, as well as the possibility that you have a predetermined angle already.

For chamfers, however, you usually see them at 45-degree angles. Now, you can see angular variations from time to time, and based on the needs of the design. But, a timber chamfer will mostly conform to a standardized angle rating.

What Are They Used For?

Of course, you can’t just get a chamfer or a bevel without examining what you want to achieve here.

You’d find that beveled corners tend to be more multi-purpose in their overall functionality. They can be decorative, but they can also be functional with their safety usefulness. Chamfering, though, is mostly done to be functional. In most cases, anyone who engages in this practice is mostly just doing it to ensure that the product is safe and easier to access.

The Beauty Comparison

Now, you might be wondering – which is prettier? Should I just go for a wood-beveled edge? Or should I use a chamfer edge instead?

In general, beveled edges would most likely take the cake here. They tend to be more decorative, with their ability to improve visual interest and add a general layer of improved sophistication to the overall look of your product.

Of course, this isn’t to say that a chamfered edge will look ugly. But, as we said earlier, these edges tend to be more focused on functionality and not aesthetic appeal.

Whatever you choose will work, but most manufacturers tend to go with the former. So, you might want to keep that in mind.

The Inclusion Of Transitional Elements

This is usually one area that tends to be overlooked a lot. But, when deciding in the bevel vs chamfer edge debate, it could easily swing your decision.

With a beveled edge, you have something that can easily serve as a transitional element that stands between materials and surfaces. This means that bevel construction allows you to achieve a much smoother transition and avoid any sudden switches.

On the other hand, you can achieve a bit of transitional success with a chamfered edge. But, like we said earlier, the major reason why these edges were created is mostly to serve safety and functionality purposes.

So, what does this all mean? The bevel-cut definition easily shows that it is more of a flexible and versatile option. With its ability to blend functionality with aesthetic appeal, and the fact that it also allows for easier transitions, you’ll find that this edge can be more flexible overall.

Chamfered edges are also quite effective, although they tend to focus more on the functional side of edge formation. As such, you need to consider what you hope to achieve here.

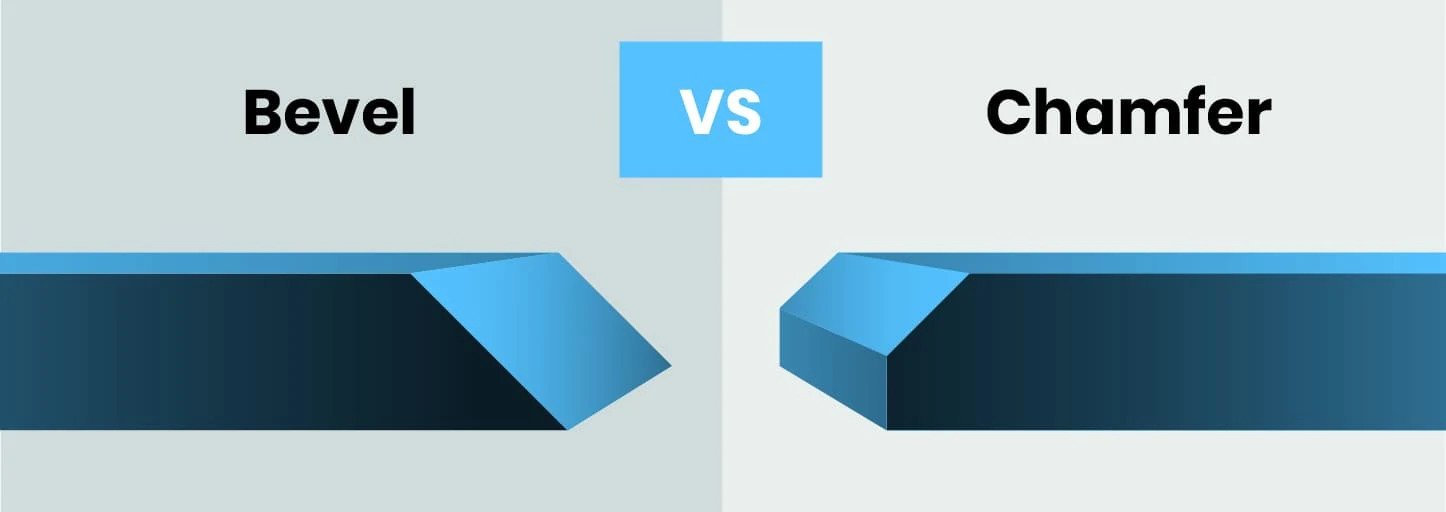

Bevel vs Chamfer: Method Of Measurement

Next on the general list of points in the comparison between a bevel and a chamfered edge is the topic of measurement.

The Measurement Dynamics Of A Bevel

As far as woodworking and product development goes, the beveled edge mostly gets measured based on the angle of the sloping surface that you get when you implement the cut. The measurement is taken in the form of degrees, since it looks at angular measurement dynamics.

So, when you see that a bevel is described as a 45-degree angle, it just means that the cut was made at that specific angular direction. That said, you also need to keep an eye on the measurements for width and depth when it comes to these edges. In some cases, manufacturers can provide details of those as well, offering a more vivid explanation of the angled cut.

How Chamfers Are Usually Measured

As for chamfers, you usually have a distance component added to the size of the cut that has been made to form the sloping edge – instead of just a specific angle.

First off, you have linear measurements, with these edges being measured in straight dimensions. This way, you get better clarity when it comes to the width of the chamfered edge and how deep the cut actually goes.

Just as well, some manufacturers also implement the distance from the corner when measuring the size of a chamfered edge. Essentially, this involves measuring the distance of the point where the edge meets your surface to the original corner of the object.

Possible Overlaps & The Importance Of Context

While we’re on the subject of measurements, we should note that there are possibilities of overlaps when talking about beveled and chamfered edges and their measurements.

In some cases, people can use chamfers and bevels interchangeably, switching the descriptions when talking about sloping or angled edges, all while also not adhering to a strict measurement method or technique.

Just as well, different industries tend to have their variations in how to measure and use both terms. For instance, some manufacturers can focus more on achieving angular measurements, while others might focus more on linear dimensions instead. Understanding what you’re talking about, as well as how it affects the dynamics of your project, will be especially important here.

Bevel vs Chamfer: Which Is Structurally Better?

On the next point of distinction, we should consider the structural integrity of both options. At the end of the day, the entire point of product development is to build something that is strong and that will be able to stand the test of time. And on this front, it’s important to set proper distinctions to help manufacturers see which option to choose here.

How Stable Is A Beveled Edge?

To be fair, there is a lot of stability that you can enjoy from making use of a beveled edge. These edges provide a high level of durability, and they also work to provide a stable platform for your product. Here are a few critical characteristics you might want to remember:

General Strength & Available Support

A bevel easily offers additional strength and support in several instances. For example, you can add this edge to a joint and enjoy a more solid bonding surface. So, each component of the joint is connected better, and security is even more optimal.

The Presence Of Transitioning

We should also point out that bevels help to create seamless transitions between surfaces – a point we raised earlier. This benefit is especially prominent in the carpentry and woodworking industries, and it means that you get even more overall structural integrity from your pieces.

Solidify for Decoration

At the end of the day, the fact that bevels are stable also adds to their allure. A wood bevel edge will be able to achieve higher levels of aesthetic appeal, while also being strong and stable across the board.

Understanding A Chamfer’s Stability

Safety & Accessibility Benefits

We won’t dwell much on this point – at the end of the day, chamfer planes focus more on enhancing safety and ease of access. They also make it easier to assemble your pieces, guiding components into place and ensuring that you can easily fit one part with another.

Adequately Distributing Material Stress

Also, you will find that a timber chamfer will easily be able to distribute stress much better across a material. The benefit of this is that you get a lower likelihood of stress getting concentrated at specific points of the piece. And, over time, it means that your piece will be able to last considerably longer.

So, How Do You Know Which Is Better?

When making a decision between a beveled edge and a chamfer hole based on stability and strength, your choice can be aided by considering some of the following:

Your Needs, Based On The Application

To begin with, you need to look into the requirements of your project. Bevels are the easy choice when you have only structural integrity and stability to consider, but you also need to remember that chamfers also do better to improve ease of access overall for the product. This can’t be overstated.

The Overall Material Characteristics

At the same time, you need to keep an eye on the characteristics of the materials that you’re making use of. Some piece materials are more compatible with bevels, while others would work better if they were molded into a chamfered edge.

What Are You Trying To Achieve?

The intent of the design plays a critical role here. At the end of the day, several other factors come into play when choosing between the two, and you need to see how those factors play with the structural stability requirement.

Get Help From An Engineer

If you’re still confused, then it might be worth getting professional help. A structural engineer should be able to help you understand the dynamics of these edges better, and you can easily reach out to us at KDM Fabrication to learn more.

Bevel vs Chamfer: The Cost Of Adding Extra Features To The Design

For many manufacturers, cost plays a significant part of any decision – and it should; there’s no reason why you should have to pay so much to begin with. And, with bevels and chamfers, one of the most significant costs that need to be considered will be the prices of getting additional materials and fixtures if they are needed.

So, how do both options measure up in this regard:

The Initial Material Costs

For bevels, the fact that you’re dealing with angled cuts means that you might need additional materials when implementing them into your design. From procurement to the additional material and the cost of covering for waste in the manufacturing process, there is a lot to put into consideration.

On the other hand, chamfering generally involves taking out materials as you look to create an angled edge. So, material wastage tends to be considerably lower when you have chamfer woodworking than with bevel construction.

Factoring The Overall Manufacturing Processes

The entire process of creating a bevel can involve different machining steps – from material cutting to milling – all with the objective of achieving a precise, accurate angle. You need to factor in the cost of these processes, which will switch based on the general complexity involved and the level of precision you want to achieve.

Chamfers, on the other hand, are mostly created with simple tools. As such, the processes involved in chamfer woodworking tend to be more straightforward. And, a direct consequence of this is that you probably won’t have to spend so much money.

The Cost Of The Human Component

We also need to factor in the fact that you will need to pay professionals to make both. Now, because of the intricacies involved in making bevels, you can find them to be a bit more expensive on the labor front. Making a chamfer hole won’t cost so much, since the process is pretty easy to implement.

Complexity In The Design Schemes

When you see an elaborate bevel design, you can just imagine how much it’ll cost. These designs usually require more precise angles, and this means that the design process won’t just be straight and easy. The higher the complexity involved, the more you end up paying overall.

As you would imagine, chamfers are the literal opposite here.

Tools and Apparatuses Used In Your Design

For making bevels, you will need to get specialized tools and equipment – tools which, as you would imagine, will cost a lot of money. Those used in chamfer woodworking tend to be more readily available, so your cost profile will also not be quite as high here.

Your Precision Requirements, & The Tolerance Range

If you have a woodworking or metalworking project with a tight tolerance and high precision requirement, then you’ll most likely be working on a bevel design. Achieving these types of designs requires higher budgets – something that you most likely won’t have to deal with when you’re working with a chamfer design.

Bevel vs Chamfer: How Do You Choose?

Now, we have all the points in. To help you come to a conclusion on which option to choose here, consider some of the following requirements and how they might factor into your decision:

Your Goals And Priorities Should Come First

The first thing that should inform your decision is your priority. If you’re more focused on strength and optimal bonding between the surfaces you’re looking to join, then a bevel should be your top pick.

Chamfers, though, focus more on taking out sharp edges and improving safety and access to your piece. If that’s what you need, then choose them.

Does Your Choice Make Your Piece Look Good?

These days, aesthetic appeal is one of the biggest requirements for anyone looking to create a product. And, if you’re focused on this, then you might want to consider using a bevel. With their sophistication and ability to incorporate smoother transitions, bevels easily provide a massive aesthetic bump to your project.

What Material Are You Using?

You should also focus on the material of the piece itself. Bevels work better with materials that easily conform to angled cuts – some grades of plastics, wood, etc. For chamfers, you would probably get better service with a material that responds well when you take out parts of it to create angled edges.

Is Your Product Safe?

Safety is generally a significant stipulation for most product manufacturers. When you see that sharp corners pose a threat, you might want to choose a chamfer. These edges are designed primarily to optimize safety, and you might want to consider them overall.

How Much Are You Working With?

Per usual, look into your budget and consider which choice will work best for you. As we explained, bevels tend to be more expensive to create and work with – even though their benefits are usually higher compared to chamfers. So, conduct a cost-benefit analysis to discover which works better based on your available budget.

Conclusion

All in all, bevels and chamfers are solid options for anyone looking to create an edge – whether in woodwork, metalwork, and much more. However, while both can be used interchangeably, understanding their distinctions will help you to decide which is better for you.

If you’d like more clarity on this subject, feel free to reach out to us at KDM Fabrication.

More Resources:

Bevel vs Chamfer vs Fillet