Comparing CO2 and fiber lasers will help you choose the best choice for your application. Depending on how you want to use it, the material qualities and level of precision needed will determine which option is best.

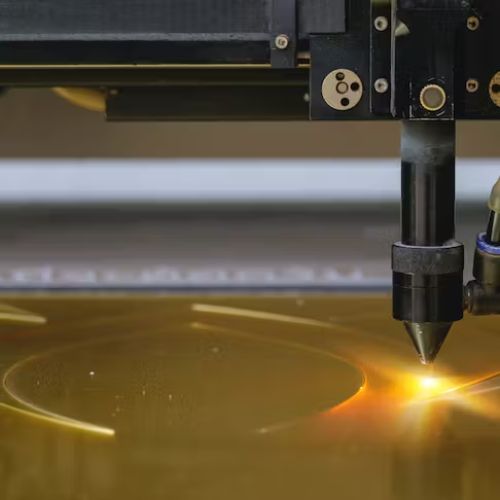

Metal has a higher absorption of laser beam energy than CO2 lasers, hence fiber lasers perform better when cutting for metal. Due to its improved precision, faster processing rates, and roughly 50% cheaper operational costs. They are a flexible and reasonably priced solution for many different uses.

Materials Cuttable by Fiber Laser

Materials Cuttable by CO2 Laser

Putting CO2 and Fiber Lasers Side by Side for Comparison

Source of Laser

- CO2 lasers create laser beams by using a mixture of gases as the laser medium, namely carbon dioxide, nitrogen, and helium.

- Fiber lasers employ a fiber optic cable doped with rare-earth elements such as erbium, ytterbium, or thulium as the laser medium. They operate using a solid-state laser source.

Duration

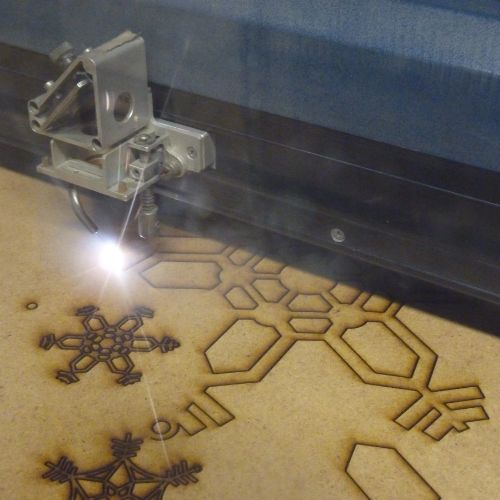

- Due to their longer wavelength, CO2 lasers are excellent for cutting non-metallic materials such as textiles, wood, acrylic, plastics, and certain metals that have reflecting coatings.

- Metals are better at absorbing the shorter wavelengths used in fiber lasers. That’s why they cut through a wide range of metals, including copper, brass, aluminum, sheet metal, titanium, and stainless steel, so remarkably effectively.

Effectiveness and Strength

- Although CO2 lasers are well-known for their adaptability, they often perform less well when cutting metal.

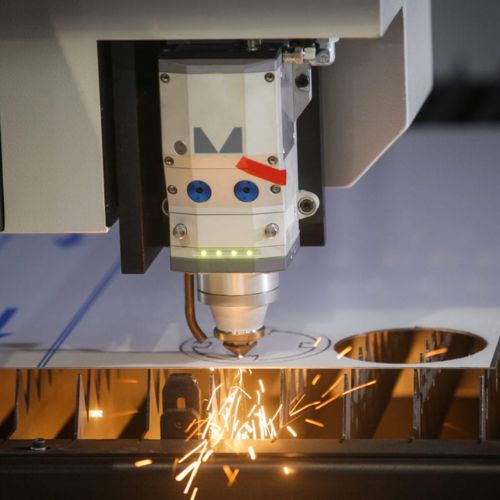

- Fiber lasers’ increased power density and shorter wavelength make them extremely effective at cutting metal.

Velocity of Cutting

- In comparison to fiber lasers, CO2 lasers may cut metal more slowly.

- Because of its superior absorption by metal surfaces and higher energy concentration, fiber lasers can cut through metal more quickly.

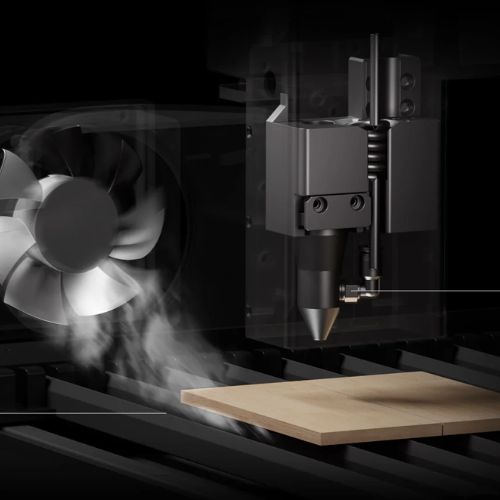

Maintenance

- CO2 lasers need frequent maintenance and gas replenishing because of its more intricate gas systems.

- Fiber lasers require less maintenance and last longer because of their more straightforward solid-state construction.

Key Characteristics of CO2 and Fiber Lasers Comparing Them

Materials for Cutting

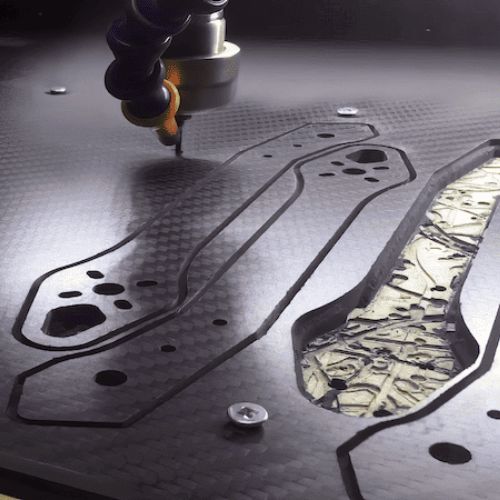

Because of their intensity and speed, fiber lasers are frequently a suitable choice for thin metal sheets. Additionally, they can work with a range of materials.

Uses

Both are excellent choices as well for this task. But fiber lasers are more efficient, and more effective.

Production Volume

The quickest method now in use is fiber laser data processing. In addition, CO2 lasers work well in spite of their inherent speed.

Spending Plan

One factor contributing to laser cutting’s high cost is the quantity required for setup. In addition to having a longer history, CO2 laser technology is also less expensive.

Security

It could be dangerous to use a laser cutter. Both CO2 and fiber lasers carry a risk of permanent harm, especially to the eyes when handled improperly. This is why using safety gear when using laser cutters are necessary.

Repair

This is the ideal operating environment for fiber lasers. The optical system requires little maintenance and can operate in a variety of environments. CO2 laser operations are more challenging.

Advantages and Disadvantages: CO2 vs. Fiber Laser

Advantages of Fiber Laser

Better Quality

It gives you increased accuracy and stability, allowing for a thinner cutting line and steady operation.

Faster and More Reliable Cutting

Outstanding dependability and a high level of intensity that allows for faster processing.

High Efficiency

A 30% increase in electron-conversion efficiency translates into more power-efficient operations.

Plain and Simple

Compared to other techniques, using a fiber laser is very easy.

Maintenance-free

Because of its effectiveness, fiber lasers are more economical to employ.

Disadvantages of Fiber Laser

High Purchase Cost

Fiber lasers require a substantial upfront financial investment even with their low operating expenses.

Gases Utilization

For purging, fiber lasers often use a lot of either NO2 or O2 gas.

Complex Materials

Reflective materials like copper and aluminum can be difficult for fiber lasers to process.

CO2 Laser Advantages

Technological Edge

The market is full of professionals who are knowledgeable about solving typical CO2 laser-related problems.

Ability to Adjust

Due to their versatility, CO2 lasers can be used for a variety of laser applications.

Disadvantages of CO2 Laser

Upkeep Difficulties

The CO2 laser’s specifications could interfere with the industry’s regular business operations. Their ideal operating conditions are also necessary.

Weak Speed

CO2 lasers taking a long time to finish tasks. CO2 lasers are completely unmatched in terms of thinnest parts.

Which Technology Has a Faster Cutting Speed?

In comparison, fiber lasers can cut thinner workpieces at far quicker speeds.

The cutting speed of a 2 KW fiber laser is usually equal to that of a 5 or 6 KW CO2 laser.

How Do CO2 and Fiber Lasers Differ From One Another?

The majority of the materials that each laser can cure depend on its wavelength.

- A CO2 laser’s wavelength is usually around 10,600 nm.

- While a fiber laser’s wavelength is usually 1,060 nm.

Fiber lasers often have a number of advantages over CO2 lasers.

FAQ Regarding Fiber Laser

What Does the Term “Fiber Laser” Mean?

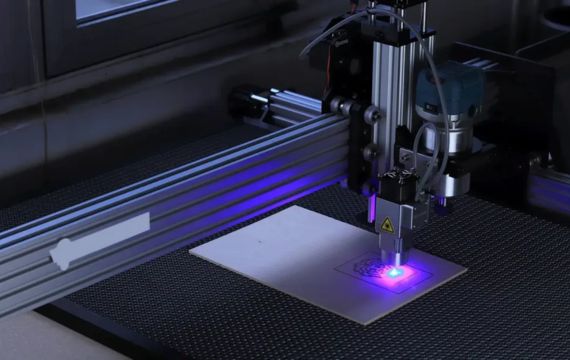

The fiber optic delivery system that gives the cutting head of the laser machine a powerful, concentrated light source is called a fiber laser.

How Do Fiber Lasers Operate?

Light is delivered through the fiber to the CNC-controlled cutting head from the laser cutting machine’s resonator.

What Use Does a Fiber Laser Serve?

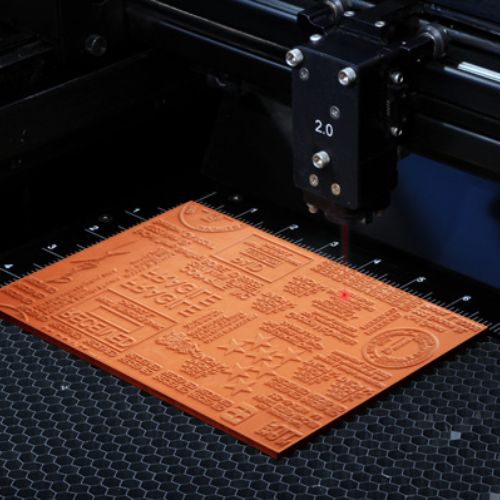

- Cutting

- Marking

- Welding

- Cleaning

- Texturing

- Drilling

- Etc.

Does a Fiber Laser Have a Long Life?

Yes. Fiber laser cutters typically have a lifespan of 100,000 hours.

What Can a Fiber Laser Not Cut?

MDF, which mostly consists of fiberboard, wood fiber, and plant fiber, as well as some materials composed of adhesive-based artificial board and urea-formaldehyde resin, cannot be cut by a fiber laser cutting machine.

FAQ Regarding CO2 Laser

A CO2 Laser: What Is It?

The term “CO2 laser” describes the laser’s creation method. Using a range of techniques, a resonator that was purged with CO2 gasses at high velocity (using blowers or turbos) divided the ions of light particles.

How Do CO2 Lasers Operate?

When sufficient light is produced by the CO2 resonator, it is distributed differently than with the fiber optic approach. A device known as a “beam path delivery system” is used to deliver the beam using reflection and refocusing along a winding path that is protected by “laz gasses”.

To keep the path clear of dust and impure, which could impede the delivery of the laser’s maximum intensity.

In What Scenarios Is a CO2 Laser More Appropriate?

CO2 lasers are widely used for engraving and cutting non-metallic materials, such as acrylic, wood, fabrics, and polymers. When used on thicker fabrics, they work well too.