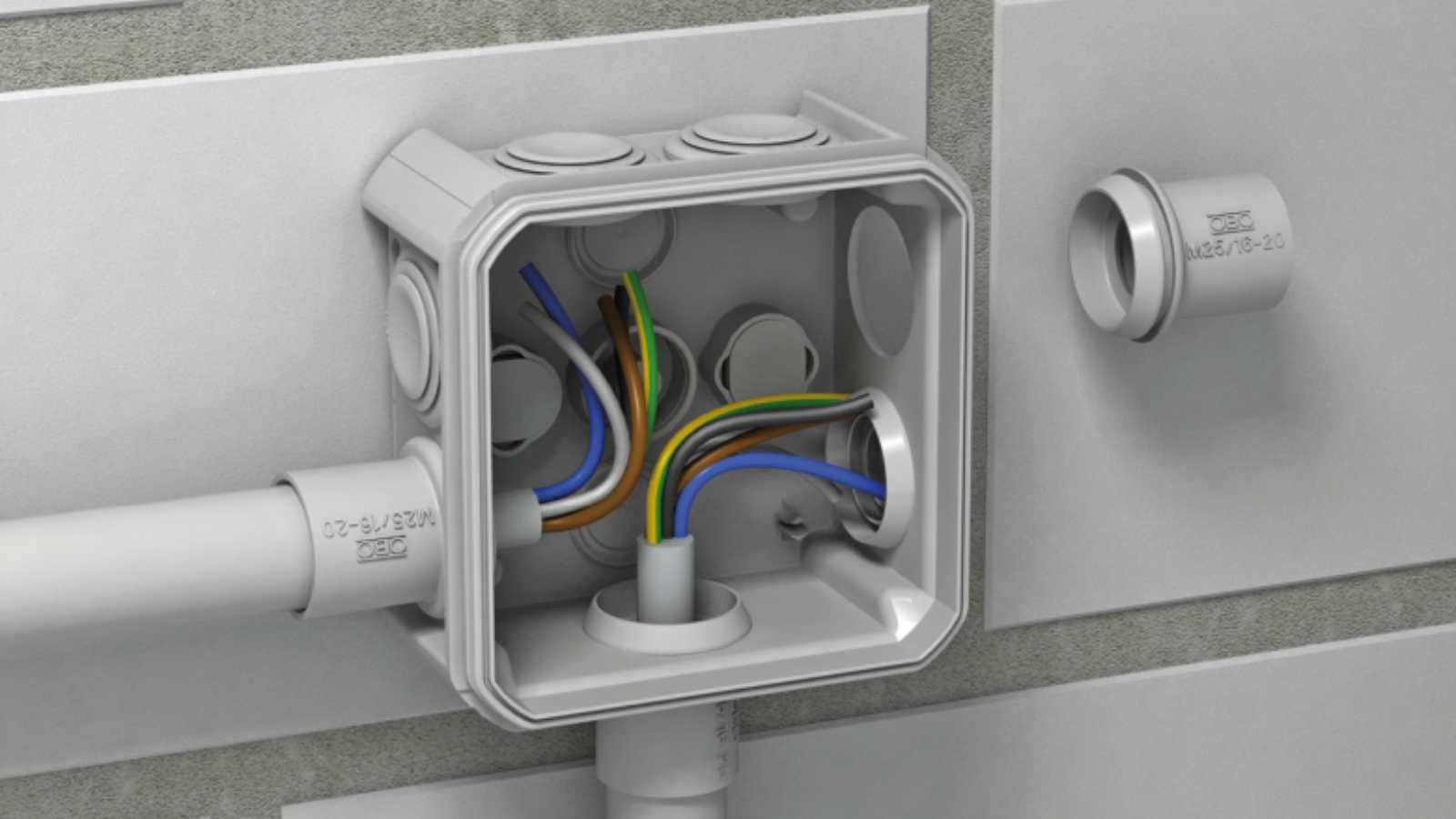

When it comes to safeguarding your electrical connections and wire splices, you need a container that can shield them from the elements and potential hazards. That’s where a junction box comes in. This crucial component of your electrical system is like a fortress for your wires, providing a secure and enclosed space to house your connections.

By providing a secure connection area, they play an essential role in electrical systems by reducing electrical risks like short circuits or electrocution.

In this comprehensive guide, you will discover the typical junction box materials, their pros and cons, and how to pick the best type for your specific needs.

Types of materials for junction boxes

As you might have figured by now, you need a junction box for your electrical connection. But you should remember that the choice of material for your junction box can significantly impact its performance and durability. Each material has unique features that make it suitable for specific applications.

Junction box material selection, some common materials you will come across are plastic, metal, and fiberglass.

Plastic

Plastic junction boxes are an ideal choice if you prioritize convenience and affordability. PVC, polycarbonate, and ABS are just a few of the plastics that are commonly used in junction box construction.

PVC, in particular, is one of the most widely used plastics due to its strength, resistance to impact and chemicals, and ability to withstand high temperatures.

Another plastic frequently used in junction boxes is polycarbonate, which is flame- and UV-resistant.

ABS is also a well-liked option due to its excellent impact resistance and capacity to survive extreme temperatures.

Pros of Plastic Junction Boxes

Take a moment to consider if a plastic junction box is the right fit for you.

- Nonconductive: Plastic boxes are safer to handle and install than metal ones since they do not conduct electricity.

- Easy installation: You will find plastic boxes simple to install, particularly in new construction with exposed studs and joists. They are easy to install because the nails are fastened when delivered.

- Cost-effective: Junction box material price are economical for many applications since they are less expensive than metal boxes.

- Built-in cable clamps: This feature can keep your electrical cable securely in place, saving you both time and money.

- Lightweight: If you’re looking for a box that’s more manageable than metal ones, consider plastic boxes. They’re lightweight, making them easy to handle and move around.

Cons of Plastic Junction Boxes

- Durability: Metal boxes tend to be more durable than plastic boxes. The plastic nail brackets and screw holes are vulnerable to breakage and stripping, limiting your mounting options and making it challenging to securely attach devices like switches and outlets.

- Grounding: If you have an electrical system that needs to be connected to the ground to be safe, Plastic boxes may not be your ideal option. Using plastic can break the needed ground connection and cause a possible hazard. In this case, metal junction boxes are preferred.

Metal

If you need a junction box for harsh environments, metal ones may be a good choice for you. They are known for their strength and durability and can be made of materials such as steel, aluminum, and stainless steel, each with unique properties that are suitable for a specific purpose.

Steel junction boxes, for instance, are known for their sturdiness and durability. They are commonly used in commercial and industrial settings where extreme conditions and harsh environments require the highest level of protection. Also, aluminum is a good conductor of electricity, which makes it an ideal choice for electrical applications.

A junction box can also be made of stainless steel since it is highly durable, corrosion-resistant, and strong. It is also non-magnetic, which is beneficial in applications where magnetic interference could be problematic. Moreover, it can withstand harsh environmental conditions, making it ideal for outdoor and industrial use.

Pros of Metal Junction Boxes

- Durability: Metal junction boxes are sturdy and durable, making them ideal for use in harsh environments where they may be subjected to impact, moisture, or extreme temperatures.

- Fire resistance: You would also find that metal junction boxes are highly resistant to fire and can help contain electrical fires in the event of a fault, preventing them from spreading.

- EMI/RFI shielding: Some metals, such as steel and aluminum, can provide effective electromagnetic interference (EMI) and radio frequency interference (RFI) shielding, protecting the electronics inside from external interference.

Cons of Metal Junction Boxes

- Cost: Metal junction boxes can be more expensive than their plastic counterparts due to the cost of the materials and manufacturing processes involved.

- Conductivity: While the conductivity of metal can be an advantage, it can also be a disadvantage if the junction box is not properly grounded. Inadequate grounding can create safety hazards and cause electrical interference.

- Corrosion: While some metals are corrosion-resistant, others can be prone to rust and corrosion if exposed to moisture or other corrosive elements. Corrosion can weaken the junction box and reduce its lifespan.

- Weight: Metal junction boxes can be heavier than plastic ones, which may make them more difficult to install or move.

Fiberglass

You should try out a fiberglass junction box if you are looking for one that has excellent durability and resistance to harsh environmental conditions. Fiberglass junction boxes are lightweight, strong, and corrosion-resistant materials that can withstand exposure to moisture, heat, and chemicals.

The material is also non-conductive, making it a safe option for electrical enclosures. Additionally, fiberglass has a high dielectric strength, which means it can withstand high voltage without conducting electricity. These properties make fiberglass the right material for you.

Reinforced polyester is another good option for junction boxes. It is a lightweight and cost-effective material that provides you with sturdy strength and excellent chemical resistance. Reinforced polyester is also resistant to corrosion, making it a suitable option for harsh environments.

Pros of Fiberglass Junction Boxes

- Corrosion resistance: Fiberglass is resistant to corrosion, which is essential in environments where the junction box may be exposed to chemicals or saltwater.

- Lightweight: Compared to metal junction boxes, fiberglass boxes are lighter, making them easier to install and handle.

- Design flexibility: Fiberglass can be easily molded into various shapes and sizes, allowing for customized designs that meet specific application requirements.

- UV resistance: If you plan to use your junction box for outdoor purposes, fiberglass has excellent UV resistance that makes it suitable for outdoor applications.

Cons of Fiberglass Junction Boxes

While fiberglass junction boxes offer numerous benefits, there are also some potential drawbacks you need to consider, including:

- Limited temperature range: Fiberglass is not suitable for you if you plan to apply it for extremely high or low-temperature applications. This can cause the junction box to warp or crack when exposed to temperatures outside of its recommended range.

- Susceptibility to impact damage: Fiberglass may not be as impact-resistant as metal junction boxes, which may be a concern in applications where the box is at risk of being bumped or struck.

- Installation requirements: Fiberglass junction boxes may require special tools and techniques for installation, such as drilling or cutting the material, which may be more challenging than installing metal or plastic junction boxes.

Understanding Material Ratings

You should know that not all junction boxes are created equal. They are rated according to their performance characteristics, which are defined by industry standards such as UL, NEMA, and IP ratings.

If you want to select a junction box for a specific application, understanding these ratings is crucial.

UL Ratings

UL stands for Underwriters Laboratories, an independent safety science company that tests and certifies products for safety and performance. UL ratings for junction boxes are based on various criteria, including flame resistance, impact resistance, and electrical safety.

The most common UL ratings for junction boxes are UL 50 and UL 94. UL 50 measures the enclosure’s ability to protect against the ingress of water, dust, and other solid objects, while UL 94 measures the enclosure’s flame resistance.

NEMA Ratings

National Electrical Manufacturers Association is a professional trade organization whose goal is to develop standards for electrical equipment and systems. By giving enclosures NEMA ratings, it is possible to describe how well they protect against a variety of environmental factors.

NEMA ratings for junction boxes range from 1 to 13, with higher numbers indicating greater levels of protection against water, dust, corrosion, and other environmental factors.

IP Ratings

IP stands for Ingress Protection, a system used to rate the degree of protection provided by an enclosure against the ingress of solid objects and liquids.

IP ratings are comprised of two numbers, with the first number indicating the degree of protection against solid objects, and the second number indicating the degree of protection against liquids. For example, an IP65-rated junction box would provide protection against dust and water jets.

When selecting a junction box, it is essential to consider the application’s specific requirements and choose a box with the appropriate rating. For example, junction boxes used in outdoor applications may require a higher NEMA rating to protect against water and weathering, while those used in hazardous locations may require a specific UL rating for electrical safety.

Careful consideration of the material rating ensures that the junction box will provide the necessary protection and performance for the intended application.

Steps to Choosing the Right Material

The right material can impact the performance, durability, and safety of your junction box. Here are a few steps to follow if you want to choose a great one.

Determine the application

The first step you should take is to determine the junction box application. Junction box material size, consider factors such as the size of the enclosure, the number and type of electrical components, and the level of protection required.

Assess the installation location

After this, you must know the location where the junction box will be installed, as this is another critical factor to consider. Is it an indoor or outdoor installation? Will the junction box be exposed to moisture, chemicals, or other environmental factors?

Consider environmental factors

Environmental factors such as temperature, humidity, and corrosive substances can impact the performance and durability of a junction box. It is essential to consider these factors when selecting a material.

For example, if you will be exposing the junction box to harsh chemicals, a material like fiberglass or stainless steel may be a better choice than plastic.

Understand material ratings

Different materials have different ratings, such as NEMA and IP ratings, which indicate the level of protection they offer against environmental factors. Understanding these ratings can help you choose the right material for your junction box.

Determine budget

Finally, it is important to consider your budget when selecting a material for your junction box. Different materials have different costs, and some may be more expensive than others. Consider the long-term cost of the material, including its durability and maintenance requirements, as well as the initial cost.

Conclusion

If you have questions or need assistance choosing the right material for your junction box, we are one call away!

You can always depend on our team of experts to help you get the perfect electrical solution.

More Resources:

Terminal Box Vs Junction Box – Source: KDM

Junction Box Vs Pull Box – Source: KDM

The Different Types Of Electrical Boxes And How To Choose The Right One – Source: KDM