What Is Metal Marking?

Metal marking refers to creating marks of various specifications on your metal. These specifications can be of different patterns, sizes, and thicknesses. Depending on your metal marking tools, you can either have permanent or temporary metal-making.

Advantages Of Metal Marking

The main advantages of metal marking are:

Easy identification of your metal; proper metal marking allows for easy identification of your metals. This is critical, especially when storing them for different usages.

Product marketing; you can use metal marking techniques to market your product effectively. This is by using attractive methods like multiple colors to market your metal product.

Allows for unique decoration; you can use different metal marking techniques to decorate your metals. Such decorations appeal to the eyes and increase the value of your metal product.

Choosing Metal Marking Equipment

Important considerations when selecting your metal marking equipment are:

Cost of the metal marking equipment: The different metal marking equipment available have varying costs due to their marking effect on your metal. Before selecting the right equipment, you must consider your budget and the type of metal marking you want.

Type of metal marking you require: The marking you want on your metal determines which equipment to use. Using a cost-effective metal marking ink, you can temporarily mark your metal.

Permanent marking requires complex equipment like a stamp or laser cutting machine. Permanent marking is usually expensive compared to temporary metal markings.

Marking speed: The speed of a particular metal marking method is vital, especially when you are bulk marking your metals. Automatic marking machines tend to mark your metals faster and more economically than manual metal marking machine methods.

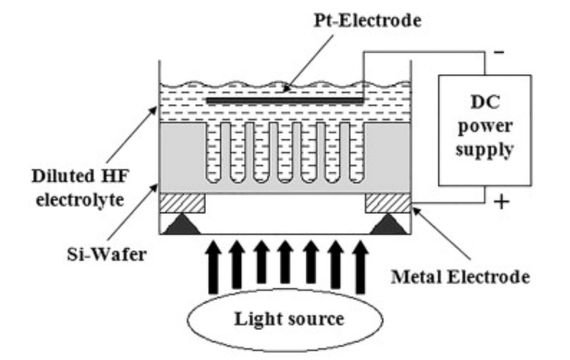

Electrochemical Metal Marking

Electrochemical metal marking involves using electrolytic fluids and electrical current to mark and label your metal product. The first step in this method is determining the electrolytic fluid to use. This is usually an electrolytic fluid.

You must also set a cathode and an anode part on your solution. Both the cathode and anode should be of the same metal type you want to mark. Once you set the electrolytic fluid, you submerge the cathode and anode in the solution.

You then have to pass an electric current to form a circuit. The circuit facilitates the electrolysis process, creating marks on your metal surface. Once you have the marks, you must rinse your metal to remove the acidity.

Electrochemical marking gives unique marks on your metal which can increase the value of your metal work. Using an electrochemical method to mark your metal is an expensive option due to the different acids you need. Therefore, you need a proper budget before considering investing in this method.

Laser Metal Marking

Metal marking laser is a technique that uses a laser machine to direct laser beams on your metal to form a mark. The marks from this process are durable since the laser beams penetrate the surface of your metal.

Additionally, the process requires using a laser machine to generate light beams that you focus on your metal surface. The beams create a pattern depending on your configuration by transferring heat energy to the surface.

Directing the light beams allows the machine to target specific areas of your metal, guaranteeing permanent and precise markings. Common metals you can use laser marking include aluminum, steel, stainless steel, lead, and magnesium. The main benefits of using laser marking are:

- Cost-effective

Laser marking only requires the laser machine for it to be effective. This makes it a cost-effective method to use compared to the other methods. The precision of this method results in less material wastage.

- Permanent marking

Laser metal marking machine uses laser beams to make markings on your metal. These beams create deep markings, which makes them permanent.

- Environmentally friendly

Less material wastage during the marking process makes laser metal marking machine an environment-friendly option. The primary limitations you should expect when using this method include;

- High purchasing cost

The initial cost of purchasing this machine is relatively high than purchasing other marking machines. You, therefore, have to have a proper budget before buying it. After purchasing your laser metal marking machine, the budget should also consider the installation cost.

- Skilled professional to operate

The operations of a laser marking machine require a skilled person. Where such a person is not available, operating this machine becomes impossible.

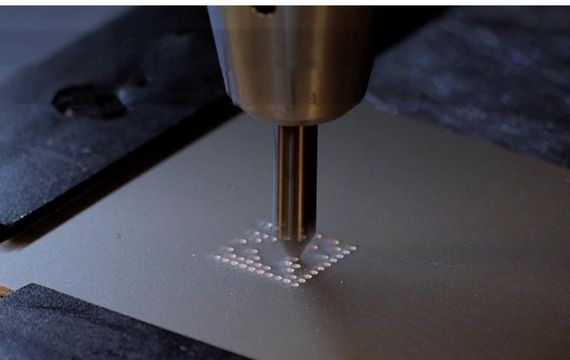

Dot Peen Marking Metal

This refers to making markings on your metal using a special peen. The process creates different types of markings depending on the peen’s thickness. Dot peen marking machine’s working involves using a single pin to create different marks that are deep on your metal surface.

The dot patterns can create varying characters like batch numbers, serial numbers, and data codes. Besides, the benefits of using dot peen marking to mark your metal are:

- Permanent and Durable Marking

Permanent metal marking, dot peen marking allows you to make permanent markings on your metal. The durability and visibility of these markings help in saving resources.

- High-Speed Operation

This method is fast and effective and can deploy in bulk marking of your metal. Its compatibility with various methods allows for practical usage.

- Usage Flexibility

Dot peen is available in two options to give you flexibility in your choice. These two options are pneumatic and electronic. The pneumatic option uses compressed air to mark your metal. An electric metal marking machine, an electric option uses electricity to keep your metal.

However, you may experience the following setbacks when using this method:

- Low Mark Quality

This method offers low-quality marks on your metal compared to laser marking. This can affect the overall quality of your product, mainly if you use the decoration technique.

- Slow Speed

The method relies on a single pin to create the marks you want on your metal. This lowers the speed of marking your metals, which can limit bulk marking.

- High Maintenance Cost

Due to the wear and tear, you must frequently replace the carbide pin. This increases the overall maintenance and operational cost of your machine.

Inkjet Marking Metals

Inkjet marking metals refers to using an inkjet marking machine to mark your metals. The marking process works by configuring the machine as per the specifications you want for the marks.

As the machine moves across the metal surface, it creates the marks you want, depending on the configurations you set.The advantage of this method is its compatibility with various metals. You can adjust the speed by checking on the controls allowing bulk marking of your metals.

Flexibility is a critical element of this machine since it allows for the complex marking of your metals. Cost, however, is the main limitation of using this method.It is more expensive to purchase the machine and frequently replace the ink. You also have to maintain your machine, which can be costly.

Applications Of Metal Marking

Metal marking plays a vital role in marking steel coils and drums. The markings give these coils and drums unique identification. You can also mark these items with vital information that facilitates customs clearance and usage. News you can find in these items includes country of origin, their purpose, and quality standards.

Printing vital information is possible through metal marking on aluminum plates and sheets. Information on these sheets and plates includes quality standards and country of origin. Such marks help in knowing the conditions you need for these sheets and plates before using them.

People Also Ask:

Yes. It is possible to mark metals permanently.

This is by using durable metal marking methods like engraving or embossing. You also must select a durable painting option if you consider painting your mark on the metal.

Metal engraving is a type of metal marking. However, metal engraving is a permanent procedure, unlike metal marking, which can be permanent or temporary.

You need fewer resources when you use metal etching than metal engraving. This includes the cost of marking and the time you use in metal marking. Using fewer resources makes metal etching the best option for bulk marking your metals.

Resources: