Custom Safety Sign Manufacturer

KDM manufactures a wide range of safety signs that are specifically designed for cautious behavior and promoting safety in the workplace. All our safety signs are guaranteed to meet OSHA, ISP, BS5499, and more standards. We use different sheet metal materials that are printed with instructions and information about safety. These are available in customized designs, styles, and sizes. It is also laminated to ensure long-life service of up to 10 years. Contact us today for your order!

KDM Safety Signs Capabilities

KDM is an expert in different sheet metal fabrication for producing metal parts such as safety signs. Therefore, you can assure that we have full capabilities in fabricating a wide range of safety signs for ornate buildings, workplaces, office blocks, and more. Through our advanced sheet metal fabrication, we can customize safety signs such as:

- Hearing and Eye Protection Safety Sign

- Danger Keep Out Sign

- Use Hand Rail Warning Sign

- No Smoking in this Area Sign, and more

KDM offers a wide range of custom safety signs to meet your requirements!

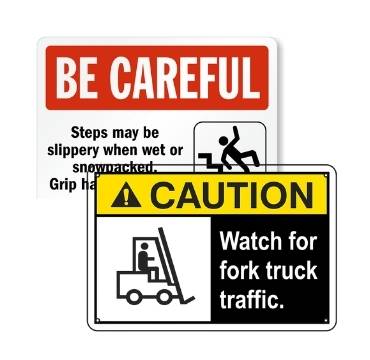

Featured Safety Signs

Custom Safety Signs to Skyrocket Your BusinessKDM is a supplier of custom safety signs that are manufactured using high-quality sheet metal materials such as stainless steel, aluminum, and more. We guarantee that all safety signs are durable and rust-proof. You can choose different colors, shapes, and sizes. These are also available in custom wording with different languages, logos, and images. All our safety signs are printed using traffic-grade inks and inkjet printers. For bulk orders of custom safety signs, request a quote from our team today!

KDM is a supplier of custom safety signs that are manufactured using high-quality sheet metal materials such as stainless steel, aluminum, and more. We guarantee that all safety signs are durable and rust-proof. You can choose different colors, shapes, and sizes. These are also available in custom wording with different languages, logos, and images. All our safety signs are printed using traffic-grade inks and inkjet printers. For bulk orders of custom safety signs, request a quote from our team today!

Why Choose KDM Safety Signs

At KDM, you can choose a broad range of safety signs that are high-quality, durable, long-lasting, and rust-proof.

- All safety signs are made from superior quality sheet metal materials

- 100% recyclable and eco-friendly

- Back-printed to assure maximum durability

- Features self-adhesive backing for easy mounting

- High-quality glossy finish

- Easy to clean

- Suitable for outdoor use with harsh environmental conditions

Customized safety signs are also available at KDM!

KDM Safety Signs Fabrication CapabilitiesKDM uses different sheet metal fabrication techniques for producing safety signs like the following:

KDM uses different sheet metal fabrication techniques for producing safety signs like the following:

Different Regulatory Requirements We Complied

We designed safety signs according to OSHA Standard 1910, 145. These signs don’t have burrs, splinters, sharp edges, and blunt corners. The design and applications of our safety signs are according to the OSHA standards.

Aside from that, we are also certified by ANSI standards and military standards. Therefore, you can assure the quality of our safety signs. For custom design, don’t hesitate to contact us!

KDM Safety Sign Materials

To ensure the quality, durability, and effectiveness of our safety signs, KDM used high-quality materials such as the following:

- Stainless Steel. These materials are versatile, durable, and strong. It is commonly used for industrial and architectural signage.

- Aluminum. This material features chemical resistance and abrasion resistance. Our safety signs made from aluminum feature protected graphics while keeping the symbol or message clear. It can also withstand different outdoor conditions such as cleanings, washdowns, and more.

- Steel. Safety signs made from steel are guaranteed to have high-temperature resistance. It can also withstand windy conditions for outside use. It comes with four corner mounting holes and rounded corners.

KDM can also use reflective steel and aluminum materials for safety sign production. If you want a specific material for your safety sign orders, we can customize it for you! Contact us today!

Related Resources

KDM – Your Reliable Safety Sign Supplier in China

KDM is a manufacturer of premade safety signs that are widely used for addressing hazards. We guarantee that all our safety signs meet OSHA, ISO, and other international standards. Our safety signs are easy to clean, easy to install, and printed with clear symbols and graphics.

We manufacture a broad selection of safety signs for limitless application needs. You can purchase our safety signs in different sizes and shapes available. It also comes with different materials including reflective materials, mountable substrates, adhesive labels, and more.

KDM can offer you customized solutions. We can manufacture safety signs based on your specification. Our team can also add your logo, brand name, or packaging. It is available in low MOQ to support your starting business!

Send us your inquiries today!