Metals are a categorization of select elements distinguishable by their polish, adaptability, and conductivity. They have various advantageous properties of varying degrees that make these elements highly sought after in different fields.

Strength is one of the key defining features when it comes to different metals

What Makes Metal Strong?

The strength of a metal is quantified using a few parameters. These include impact strength which gauges how much impact a metal can withstand without breaking.

Compressive strength determines the resistance of a metal against being squeezed into another metal.

Tensile strength quantifies the ability of a metal to hold out against being pulled apart.

The last one is yield strength which is the amount of stress required for metal to shift from elastic deformation to plastic deformation.

Once you have all these values, you can ultimately gauge whether the metal is strong or not.

10 Strongest Metals in the World

Here are some of the list strongest metals known for ranked:

1. Tungsten

This is the strongest metal on earth. The metal has a greyish-white shiny appearance. It is extremely dense which allows it to resist extreme temperatures as high as 3422ᵒC.

Despite its impressive strength, you will realize that tungsten is brittle and can fragment on impact.

- Tungsten’s tensile strength is the highest of all metal elements, going up to 980 MPa.

- Pure tungsten compressive strength averages at around 166,753 psi (1150 MPa).

- It has a yield strength of 750 MPa making it one of the strongest elements in the periodic table.

- Its impact strength is relatively lower compared to its other properties at only 47 MPa. Tungsten compressive strength varies with the purity of the metal. Its alloy’s compressive strengths differ depending on the type of metal infused. For example, in the case of tungsten carbide

- Its compressive strength is 4780 MPa

- Its tensile strength comes at 350 MPa

- An even lower impact strength of 12 MPa

- A yield strength of 140 MPa.

Its applications include; cutting tools, male molds, mining tools, milling cutters, wire drawing dies drills, and female molds among others.

2. Steel

Steel is one of the strongest amalgamations of iron and carbon. It has many superior properties including its high strength, durability, malleability, resistance to corrosion, and versatility. It also has a relatively high resistance to high temperatures.

The alloy is made with varying compositions and processes which alter its properties depending on the makeup of the final product.

The tensile strength of steel varies with these factors. Examples of the tensile strength of the different of steel include;

- AISI 4130 whose tensile strength is 951 MPa (1,110 psi)

- API 5L X65 has 448 MPa (65,000 psi)

- ASTM A514 has a tensile strength of 690 MPa (97,000 psi)

- ASTM A36 has a tensile strength of 400-550 MPa (57,000-85,000 psi), among others.

Steel yield strength also varies with the composition and preparation of the resulting alloy; examples of different types of steel’s yield strengths include;

- API 5L X65 with a yield strength of 448 MPa (65 ksi)

- A36 steel whose yield strength ranges from 250-400 MPa (36-58 ksi)

- 1090 mild steel’s strength is 247 MPa (36 ksi)

- Chromium-vanadium which has a yield strength AISI 6150: 620 MPa (90 ksi)

You can determine its impact strength using the Charpy Values test. Depending on its composition steel has a varying range of impact strength including;

- 1040 Carbon steel that measures 180 Joules

- 8630 low alloy steel which has 55 Joules

- 410 stainless steel that can withstand 34 Joules

- L2 tool steel with 26 Joules

The compressive strength of steel ranges from 250 MPa to 1500 MPa depending on the method of preparation and the exact makeup of the alloy. Its applications include; aerospace and automotive, construction, transportation, energy, industrial application, packaging, and art among others.

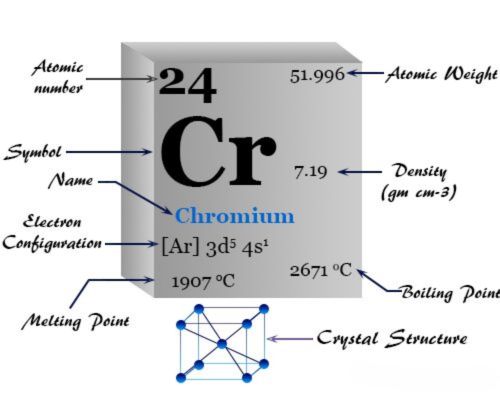

3. Chromium

Chromium is one of the hardest metals. It is steel grey and shiny and with a high melting point with an increased resistance to corrosion. Its different strengths vary depending on the composition of the element.

- The metal’s tensile strength ranges between 370 and 760 MPa.

- Its yield strength averages 131 MPa.

- The compressive strength ranges from 185 MPa to 430 MPa.

- Its impact strength ranges from 120 MPa to 150 MPa.

Chromium alloys also have varying strengths for example cobalt-chromium alloys have tensile strengths ranging from 145 and 270 MPa. Its yield strength falls between 470 to 1600 MPa. Its applications include strengthening steel, metal ceramics, chrome plating, production of alloys, refractories, foundries, and magnetic tape.

4. Titanium

Titanium is a silver-white metal. It is a lightweight metal, resistant to corrosion, with a high melting point. It is among one of the most commonly found metal elements on earth. Despite Its low density, it has a high strength.

- Pure titanium’s yield strength is at around 250 MPa

- Its impact resistance averages between 55 to 60 MPa

- The element’s tensile strength ranges between 240 to 241 MPa

- Its compressive strength ranges from 130 to 170 MPa

Its alloy also has different strengths, that vary with the composition of the added elements included in the alloy as well as the element’s strengths. For example, if you look at titanium carbide, you will realize that the metal is an incredibly strong alloy.

- Its tensile strength is 310 MPa

- The alloy yield strength is 20 GPa

- Its compressive strength is 3789 MPa

The applications include; the medical field, aerospace industry, chemical, desalination plants, ships, submarines, and jewelry among others.

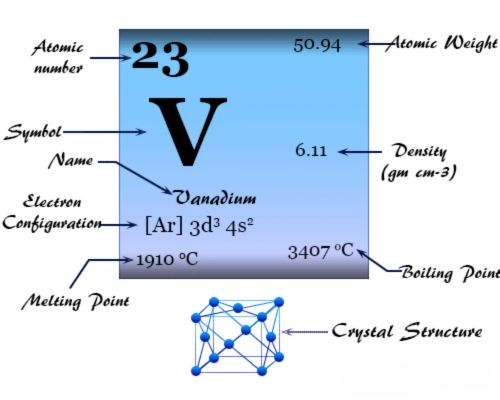

5. Vanadium

This is a transition metal that is silver-grey. Vanadium is not commonly found in its pure state but it is derived from plenty of other elements. It also has a low neutron-absorbing properties.

- Vanadium has a tensile strength of 800 MPa (116,000 psi)

- The element has a yield strength of 776 MPa (113,000 psi)

- Its compressive strength ranges between 125 to 130 MPa

- Its fracture toughness ranges from 70 to 150 MPa, and its impact strength varies depending on the composition of the vanadium

One of the stronger vanadium alloys is the ferrovanadium which incorporates iron. Its tensile strength is approximately 1200 MPa. Its impact strength can range from as low as 2.80 j/cm2 to as high as 13.91 J/cm² depending on the exact composition of the alloy.

Applications of vanadium include; making steel alloys, space vehicles, nuclear reactors, and aircraft carriers, the medical industry, ceramics as a pigment, and dies.

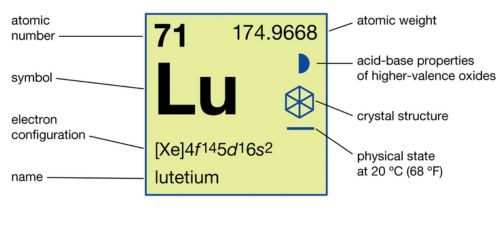

6. Lutetium

This is a silver-white metal that is very rare and therefore expensive. It falls into a category of metal referred to as lanthanides and is arguably the strongest in the group. It is not mined in its pure form but extracted from lutetium trichloride.

- The metal’s tensile strength ranges at 140 MPa (20300 psi)

- Its yield strength is approximately 60.0 MPa (8700 psi)

- Its Vickers hardness is approximately 1100 MPa and its Brinell hardness ranges from 890 to 1300 MPa

Lutetium’s applications include; the petroleum industry, electronics components, used in cancer therapy, and impurity sensors in metallurgical and denture production.

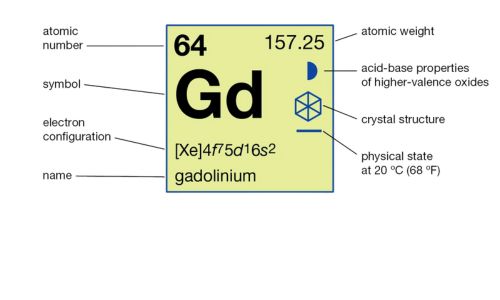

7. Gadolinium

This is a rare silver-white earth metal. It is naturally found oxidized and has to be processed to obtain its pure form. The metal is ductile as well as malleable. It is highly toxic but can align with magnetic resonance imaging also known as MRI.

The various strength parameters of these metals vary depending on the structure and composition of the metal.

- Its yield strength is around 635 MPa

- The metal tensile strength is approximately between 170 to 430 MPa

- Its compressive strength ranges between 160 to 300 MPa

- Fracture toughness of this metal ranges between 45 to 90 MPa

Its applications include; medical applications, industrial applications, nuclear energy, and electronic and optical devices.

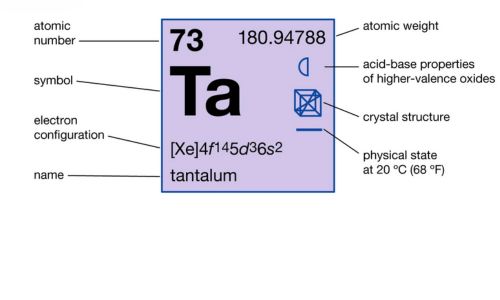

8. Tantalum

This is a transition metal that is a blue-gray transition. It is a very good conductor of heat and electricity. It is also highly resistant to corrosion.

- Tantalum’s yield strength ranges between 100-200 MPa

- Its tensile strength is approximately 900 MPa

- The impact strength is about 1200 to 400 MPa

- The compressive strength of the metal ranges from as low as 135MPa to as high as 1060 MPa

Its alloys that contain various percentages of other elements will have varying strengths depending on the structure and makeup of the alloy. Its applications include; electrical applications and appliances, industrial applications, aerospace, defense, research, and development.

9. Zirconium

The element is a shiny greyish-white transitional metal. It has a high resistance to heat and corrosion and I very ductile. This element is derived from a mineral known as zircon. The metals are also malleable and ductile.

- Its yield strength is approximately 230 MPa (33400 psi)

- The element’s tensile strength is 330 MPa (47900 psi)

- Its Vickers hardness is 150 MPa and its Brinell hardness is approximately 145 MPa

The different alloys have varying strengths such as Zircaloy-4, whose yield strength is approximately 381 MPa and its tensile strength of about 514 MPa zirconium hydride, its yield strength of 709 MPa and tensile strength of 998 MPa.

Its applications include; nuclear reactors, industrial applications, medical and dental, ceramics and refractory materials, antiperspirants and lotions, production of abrasives.

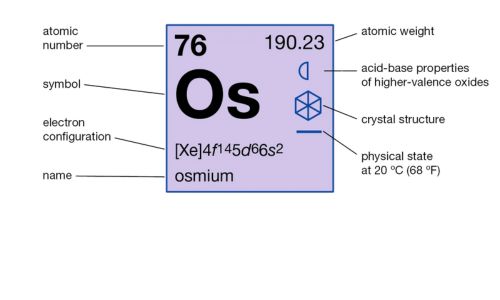

10. Osmium

This is a gray sometimes blue-white metal that is equally hard and brittle. It is derived from alloy metals for example platinum. This element is one of the densest elements that is naturally occurring.

- Its tensile strength is 2000 to 7000 MPa.

- The element has a fracture toughness of about 120 to 150 Mpa and an endurance limit of 800 to 3600 MPa

- Compressive strength of the metal ranges between 1000 to 3600 MPa

You can use this metal in many applications such as fountain pen tips, instrument pivots, electrical contacts, abrasive and polish lens polishing, jewelry, alloying agents, catalysts, and the nuclear industry.

Conclusion

The difference between the strongest metal and the weakest metal is, strength is largely dependent on their chemical structure and composition. These metals are often amalgamated with other elements to increase tier strength as well as other properties.

Again, you should realize that the purity of the metal directly affects its strength. As such the same metal may have varying strengths depending on the grade.

More Resources:

Strongest and Hardest Metals – Source: OWLCation

Top 10 Strong Metals on Earth – Source: Sciencing

List of all Metals – Source: Thought. Co

Metal Mechanical Properties – Source: Machine MFG

Metal Strength Chart – Source: KDM