What Is Metal Strength Chart?

This is a type of chart that illustrates different strengths of metal from the stronger one to the less strong. In production, the metal strength you choose has a greater determinant in the reliability and success of the outcome.

Importance Of Knowing Metal Strength

Making the Right Metal Decision

Having knowledge on strength of metals will make you choose the right type of metal for your intended purpose use. To choose the best metal for your intended purpose, you need to use the metal strength chart for the right metal. For instance, using low strength metals instead of high strength in heavy duty application will make the structures to easily deform.

Knowing the Deformity Range

Knowledge in metal strength enables one to understand the impact a metal can tolerate before deforming. This will help especially to metal parts exposed to collisions and hitting.

Types Of Metal Strength

Tensile Strength Of Metals

This is the extreme amount a metal is going to pull or stretch before it permanently damages and fail. To know how a metal is going to perform in an application, you need to test the tensile strength.

Under tensile strength, there are three types namely;

- The yield strength, it is the point of strain where a metal will plastically begin to distort.

Once this point is reached, the deformity on the metal is likely going to get permanent.

- Breakable strength, this is the strain point when the metal will completely fail to perform.

- Ultimate strength refers to the maximum levels of stress the metal can be able to endure.

Compressive Strength Of Metals

This is the extreme amount of pressure at which the metal can be able to withstand. The compressive strength of a metal is measured using a universal measuring machine. Additionally, the universal measuring machine acts by applying an increased load on the metal.

Impact Strength Of Metals

It’s the measure of the amount of pressure a metal can hold before its failure when a sudden force is applied. Therefore, it is important to understand the levels of energy a metal is likely to hold and absorb before it breaks.

- metal square tubing strength chart

- metal tubing strength chart

- jewelry metal strength chart

- sheet metal strength chart

- ring metal strength chart

Key Parameters Of Metal Strength Chart

They include;

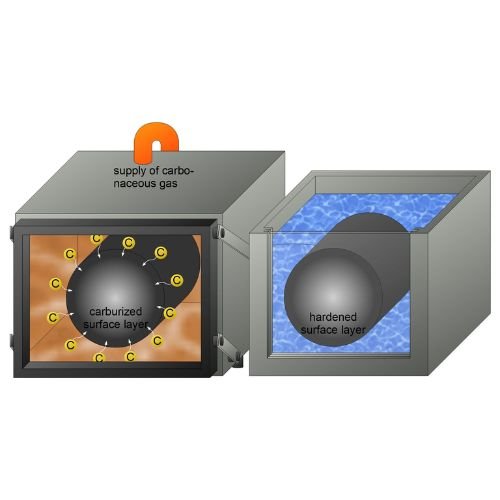

Metal Hardness

It is a metal feature that defines the metal’s abrasive resistance and surface wear. The hardness of a metal can be improved through numerous ways which include heat treatment and tempering.

Density

Different metals have their different ranging densities which has an effect on the metal’s strength levels.

Tensile Strength

It is the maximum amount a metal is going to pull or stretch before it permanently fails and damages. To know how a metal is going to perform in an application, you need to test the tensile strength.

Yield Strength

The yield strength, it is the point of strain where a metal will plastically begin to distort. Once this point is reached, the deformity on the metal is likely going to get permanent.

A table Representing key Parameters of the Metal Strength Chart

| Different types of metals | Metals tensile strength in psi | Yield strength in psi | Hardness Rockwell ( B – scale ) | Density in Kg/m³ |

| Stainless steel 304 | 90,000 | 40,000 | 88 | 8,000 |

| Stainless steel A 36 | 58 – 80,000 | 36,000 | 7,800 | |

| Grade 50 steel | 65,000 | 50,000 | 7,800 | |

| Aluminum 6061 – T 6 | 45,000 | 40,000 | 60 | 2,720 |

| Aluminum 3003 | 22,000 | 21,000 | 20 – 25 | 2,730 |

| Aluminum 5052 – H32 | 33,000 | 28,000 | 2,680 | |

| Red brass | 49,000 | 65 | 8,746 | |

| Yellow brass | 40,000 | 55 | 8,470 | |

| Phosphor bronze | 55,000 | 78 | 8,900 | |

| Copper | 28,000 | 10 | 8,940 | |

| Titanium | 63,000 | 37,000 | 80 | 4,500 |

| Aluminum bronze | 27,000 | 77 | 7700- 8,700 |

Ways Of Improving Metal Strength

It’s a process where a metal is heated and left to slowly cool removing internal stress hence easier to work with.

This is a process that involves heat treatment and it is used in cold worked and cold rolled metals.

It is a process involves the metal being heat at high temperatures then left to cool at room temperature air.

Here, the metal is heated at elevated temperatures then put into a molten salt bath or water hence increasing hardness.

The metal is strained at repeated times which reduces the plasticity thus reducing its ductility and becomes work hardened.

Few days after die casting, this process takes place at a faster rate then slowly reduces through the following days.

This process entails a metal being quenched into a heated but solid solution of an alloy during the alloying process.

Treatments on the surface of the metal are done which leaves a hard and wear resistant surface of the metal.

Often, the process is used on aluminum metal where the surface is hardened a d sealed using metal salt sealers.

The surface hardness of a metal is increased through flattening of the metal; the process is done after forming operations.

It is a process that is done on steel metal to make it ductile and improve its levels of hardness.

In electroplating, wide ranges of metal finishing process like gold plating and silver plating are used to improve the hardness.

People Also Ask:

Strength in metals is used to describe the level at which a metal is able to resist any external pressure towards it. Different metals have different metal strengths hence they differently respond to external pressures when applied on them.

- expanded metal strength chart

- metal tensile strength chart

- sheet metal tensile strength chart

- sheet metal shear strength chart

- metal thickness strength chart

- metal alloy strength chart

The strongest metal is Tungsten because it possesses the highest tensile strength. Also, the metal’s melting point is outstanding since it is the highest melting point of any metal that has not been alloyed.

Tensile Strength: Tensile strength is the ability of a metal to resist any failure or deformation when external forces have been applied.

Impact Strength: This is the metals ability to resist breakage but rather absorb energy coming from the collision.

Toughness refers to the ability of a metal to resist a breakage or fracture after it has undergone a collision. Strength refers to the ability of a metal to resist deformation when external forces have been applied on it.

The metal strength and hardness are not the same. The hardness of a metal describes the ability of the metal being able to resist a scratch or a penetration from an object. Strength implies the metal’s ability in resisting deformation.

Learn More: