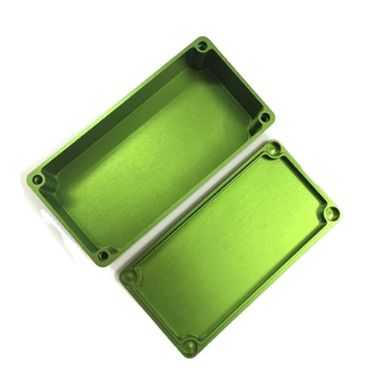

Custom aluminum boxes are made in a variety of styles and with countless features. You can specify windows, louvers, locks, gaskets, and much more. Aluminum boxes are versatile—used as electrical enclosures, mobile cabinets, storage for tools, etc. Your design selection is unlimited with KDM.

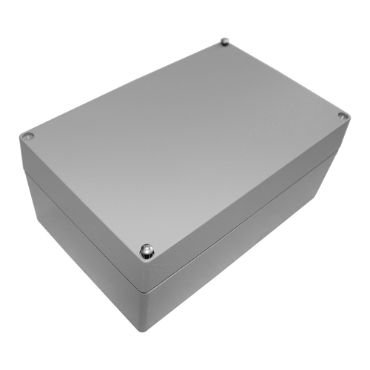

Even more importantly, we create IP-rated and NEMA-rated aluminum boxes fit for outdoor, commercial, marine, and industrial use. Simply give us your idea and requirements, and our experts will manufacture your perfect custom box.

An aluminum junction box in an enclosure houses electrical components and cables. These boxes have special fittings and cable entry points. KDM custom aluminum welding makes junction boxes lightweight and strong.

Aluminum is a versatile material, which is why it works perfectly for custom storage boxes. With its excellent impact resistance and durability, aluminum is a great choice for storage enclosures.

Hinged lids are a common feature added to custom aluminum boxes. These doors can be of any size, thickness, or shape, and you can choose to add latches and gaskets. Popular on both small and large aluminum boxes, lids offer ease of access anywhere.

Although aluminum is resistant to corrosion as it is, at KDM, we can fabricate enclosures with extra waterproof and dust-tight features. If you need IP-rated aluminum enclosures, this is your stop.

Aluminum truck boxes help keep gear and tools protected from rain and snow. These boxes are kept at the back of a trailer truck, especially useful in rural areas. With special hardware, KDM truck boxes will securely house any equipment.

Custom Aluminum Boxes by Finish

Aluminum is a lightweight material, so the boxes fabricated from it will also have that quality. It allows for these boxes to be easily moved, carried, and mounted—a versatile solution for any project.

Aluminum is recyclable, so manufacturing custom aluminum boxes is eco-friendly and affordable in the long run. You will be able to recycle or modify your box, easily giving it a second life.

Aluminum is highly weldable, bendable, and ductile. This means that it is easy to machine and customize at any time. KDM offers countless designs, features, and manufacturing processes to support further customization.

Aluminum boxes have high weight-to-strength ratios, meaning that it is a strong material. Whatever the aluminum box will be housing is safe from corrosion and impact. Moreover, aluminum becomes stronger in cold temperatures, so if those are the working conditions, aluminum outperforms steel.

Custom Aluminum Box Applications

Aluminum boxes are very versatile and can be used in many different applications. For instance, they can be used to carry or store tools, protect a mounted appliance or cables, and more. Some industries that commonly use custom aluminum boxes include:

- Energy

- Automotive

- Construction

- Transport

- Repair & Maintenance

- Telecom

- Aerospace

Aluminum Grades and Alloys

There are currently eight series of grades used to categorize the many alloy kinds that are accessible when working with aluminum.

| Series | Contents | Application | Main Property |

| 1000 | Pure aluminum | Versatile | Ductile |

| 2000 | Copper + aluminum | Aerospace | Hardness |

| 3000 | Manganese + aluminum | General-purpose | Good finish |

| 4000 | Silicon + aluminum | Automotive | Thermal conductivity |

| 5000 | Magnesium + aluminum | Marine | Corrosion resistance |

| 6000 | Magnesium + silicon + aluminum | Construction | Strength, machinability |

| 7000 | Zinc + aluminum | Aerospace | Strength |

| 8000 | Other (e.g. iron, lithium, etc) | Engineering | Varies by alloy |

The most common alloys used for custom aluminum boxes are 6062, 7075, and 3003. You can always contact KDM support to discuss the best alloy for your custom project.

Custom Aluminum Box Fabrication Process

Metal fabrication is the process of making metal pieces by cutting, bending, and shaping the metal. Welding, cutting, forming, and machining are examples of common fabrication techniques. Usually, the manufacturing process follows some basic steps: 3D design and approval, machining, and finishing. When designing, you would choose aluminum alloy, thickness, and features.

Machining may involve processes like cutting, bending, and welding—all with small tolerances. Our experts have experience with many techniques within each step, such as spot welding and seam welding. As for finishing, we can foam and polish your aluminum box, as well as include anodizing, powder coating, and plating. Lastly, we can even use silk-screening and digital printing to apply your logo and various symbols onto the metal surface.

Why Choose KDMfab

KDM uses cutting-edge CNC machines, TIG welding equipment, laser cutting, press brakes, and more to carry out various manufacturing operations. This ensures accurate and thoroughly processed custom products with precision tolerances. Our aluminum boxes and enclosures are used in many industries, including in aerospace, telecom, and food processing applications.

We take quality seriously. With years of experience, countless certifications of local, international, and industry standards, and strict quality control, KDM has become one of the leading metalwork factories in China.

Contact us now for high-quality, custom aluminum fabrication

Custom Aluminum Box Fabrication Supplier

Do you have a complete custom design in mind? Or do you just have a rough idea of the aluminum box that you need? In both cases, we can help with our custom engineering. We offer design assistance and 3D rapid prototyping.

Our engineering team will work with the customer to refine and finish their ideas and designs in accordance with their specifications. Additionally, we can do reverse engineering and redesign an existing idea to improve its function and lower production costs.

KDM uses innovative techniques and equipment to cut, assemble, and bend aluminum. Using various machinery, we can achieve certain designs and quality. Our welding work ensures impermeability, bending gives precise angles, and our laser cutting tolerances are some of the smallest in the industry.

Not to mention our expertise in surface treatment. KDM offers the full range of surface treatment from polishing to chemical treatments, paints, and decorative finishes. With KDM capabilities, you will have unlimited creative freedom—our experience and professionalism in metalworking allows us to service hundreds of clients flawlessly.

We hold SGS, CE, and RoHS certifications. In addition, we have received approval from several industry standards, including AS9100D, and ISO9001:2015. Our strict quality control management has been certified with ISO 9001. KDM products thrive on the world stage, as we have all the necessary international qualifications.

You can be 100% certain of our professionalism and dedication.