Step into the world of Aluminum Extrusion. Master the process, learn about the types, and explore various applications. Understand the materials and tools, and overcome common problems. This blog will guide you through each aspect, helping to become a true professional in Aluminum Extrusion.

What is Aluminum Extrusion?

At the heart of many industries lies aluminum extrusion. In a nutshell, think of it as a process, much like squeezing toothpaste from a tube. Indeed, the ‘toothpaste’ here is heated aluminum billet, forced through a steel die. With strength comparable to steel, yet lighter by 1/3, they find use everywhere.

Picture frames, car parts, aircraft components, and even your window frames, all use this process. Unbelievably, sizes range from minuscule to massive, over 180’. The versatility is endless. Trust in this process, shaping aluminum into profiles of limitless potential.

-Understanding the Properties of Aluminum!

- Lightweight

- Strong

- Durable

- Malleable

- Conductive

- Non-magnetic

- Corrosion-resistant

- Recyclable

- Non-combustible

- Reflective

- Non-toxic

- Odorless

- Impermeable

- Alloyable

How Aluminum Extrusion Works: A Step-by-Step Explanation!

Pre-Extrusion Processes!

– Billet Heating

In aluminum extrusion, an initial stage involves heating billets. Known as zarbana aluminum extrusions, they heat up to 900°F.

The heat softens the metal. This phase ensures optimal plasticity for the forthcoming extrusion. Keep billets clean to avoid surface imperfections.

– Die Preparation

Before extrusion starts, die preparation is critical. The die, shaping the 15 series aluminum extrusion, must be heated and lubricated. Lubricants prevent sticking and control the temperature. Proper preparation results in a smooth extrusion process.

– Extrusion Press

The heated, softened billet then enters the aluminum extrusion press. The press applies high pressure, forcing the aluminum through the die. Depending on the force used, different shapes and sizes are produced, like 2020 aluminum extrusion dimensions.

– Cooling Process

Next comes the cooling process. The 3030 aluminum extrusion profile cools down on a run-out table. Speedy cooling retains the shape and hardens the profile.

– Stretching Stage

Post cooling, the profiles undergo stretching. Here, the 4080 aluminum extrusion profile gets stretched on a stretcher table. Stretching corrects any twisting and keeps profiles straight. The force applied must be carefully controlled.

– Cutting Operation

How to cut aluminum extrusion, After stretching, the aluminum extrusion 8020 profiles get cut. An automatic saw makes precise cuts to desired lengths. The cutting process results in finished parts ready for use.

– Heat Treatment

Next, the extruded profiles undergo heat treatment. This phase, also known as aging, hardens the profiles. By controlling the temperature and time, aluminum extrusion manufacturers can achieve different strengths and hardness levels.

– Surface Finishing

The aluminum extrusions home depot provides surface finishing. This step includes anodizing or aluminum powder coating for improved appearance and durability. Remember, quality finishing boosts the value of the final product.

Post-Extrusion Processes!

– Cooling

After extrusion, cooling is essential. Rapid cooling, at a rate of 100-300°C per second, transforms the product. Using air or water, you solidify the shape swiftly. In this stage, aluminum extrusion accessories like cooling fans play a big role.

– Straightening

Once cooled, straightening comes next. Bosch aluminum extrusion machinery is a good example, using rollers for this job. Depending on extrusion size, 5 to 8 rollers work in concert to ensure straight profiles.

– Aging

Aging is about strength. Natural aging takes a few days at room temperature. Can art aluminum extrusion inc adopts artificial aging, heating aluminum at 350°F for eight hours, to speed up the process.

– Quenching

Rapid cooling or quenching is critical. Quenching locks the aluminum extrusion shapes and enhances the metal’s properties. An important step, it prevents warping and maintains rigidity.

– Anodizing

Aluminum anodizing is an electrochemical process. It thickens the aluminum’s natural oxide layer for better protection. It’s important in the 20×20 aluminum extrusion where enhanced durability is key.

– Thermal break

In energy-efficient constructions, a thermal break is integral. Insulating strips inside the 4020 aluminum extrusion block heat transfer, contributing to energy savings.

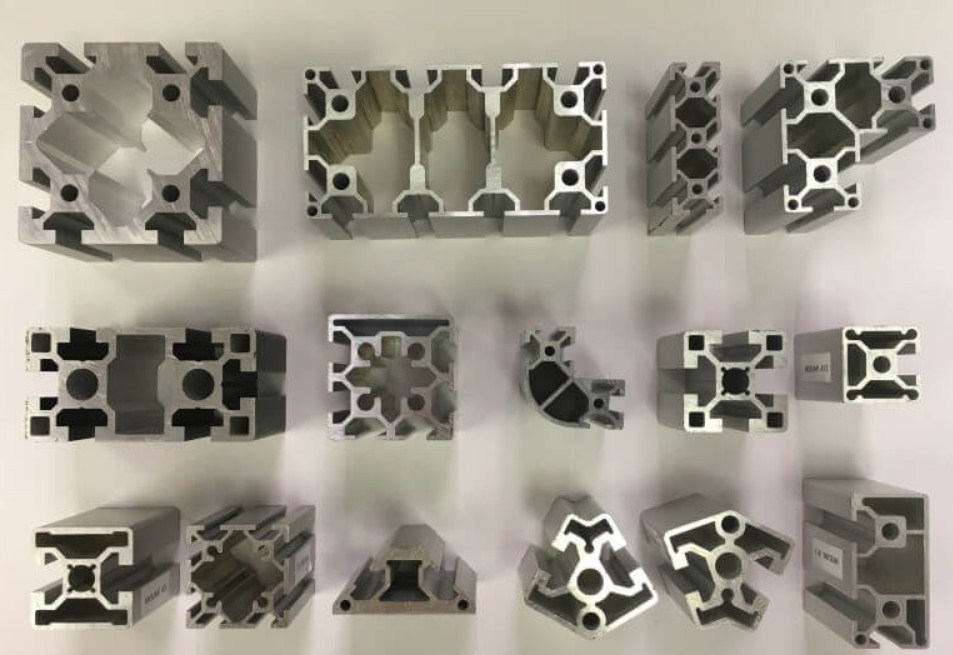

Types of Aluminum Extrusion!

o Direct extrusion

Direct extrusion is the most common method. A billet, heated to 800 degrees, gets pushed through a die. The die forms the aluminum extrusion shape.

Use in various applications like aluminum extrusion brackets is common. Experts consider the 7000 series of alloys, such as the 10 series aluminum extrusion, ideal for this process.

o Indirect extrusion

The method of indirect extrusion is slightly different. In this case, the die moves toward the stationary billet. This method reduces friction, leading to better surface finishes.

Indirect extrusion is perfect for making precise parts like the aluminum extrusion rail. The stock aluminum extrusion profiles are typically derived from this process.

o Tube extrusion

Tube extrusion is unique. A mandrel or bridge is set inside the die to form hollow sections. This technique is instrumental in manufacturing rounded aluminum extrusions for sale.

Often, you will find tube extrusion products in the form of curved aluminum extrusion or aluminum extrusion channel.

o Semi-hollow extrusion

Semi-hollow extrusion is a fusion of solid and tube extrusion. The die features a small gap for the material to flow, creating a semi-hollow shape. Used aluminum extrusions, This process is commonly used for making aluminum frame extrusions. Also, it’s prevalent in american aluminum extrusions production.

o Co-extrusion

Co-extrusion involves pushing two or more alloys through the same die. This process results in multi-layered products. For instance, aerospace aluminum extrusions use this technique for enhanced performance. The 3d printer aluminum extrusion also utilizes this method for better functionality.

o Multi-port extrusion

Multi-port extrusion, or MPE, is a type of aluminum extrusion 2020 method. Heated aluminum gets pressed through a die with many holes. This creates multiple, identical, thin tubes.

Cooling afterwards solidifies the shape. Widely used in air conditioning units, MPEs are effective and efficient. Kobelco Aluminum Products & Extrusions Inc. adopts MPE for high-quality products.

o Micro extrusion

Micro extrusion deals with very small, detailed shapes. For instance, aluminum extrusion rails need precise detailing. During micro extrusion, tiny, specific shapes are formed from heated aluminum. Tools used are microscopic in size. The process is delicate, but important. It’s vital for medical tools, electronics, and tiny machine parts.

o Impact extrusion

Impact extrusion plays a significant role in the formation of aluminum products. Aluminum extrusion scrap price is crucial here. In impact extrusion, aluminum is forced into a mold under high pressure. This pressure creates detailed, sturdy products. Objects like aerosol cans and automotive parts are results of this process.

o Conform extrusion

With conform extrusion, aluminum extrusions t slot can be formed easily. This method alters aluminum’s cross-sectional area. It changes while preserving its volume.

No heat is necessary. So, it’s energy-saving. As a result, aluminum extrusion company, Hydro Aluminum Extrusions, uses this method for some products.

o Friction extrusion

Round aluminum extrusion involves friction extrusion. Heated aluminum rotates against a die. The friction and pressure form cylindrical shapes. Aluminum tube extrusion is common with this method. The process yields seamless, strong tubes.

Materials Used in Aluminum Extrusion!

Alloy 6061

Alloy 6063

Alloy 2024

Alloy 7075

Alloy 5052

Alloy 3003

Alloy 1100

Aluminum scrap

In Aluminum Extrusion, aluminum scrap serves a dual purpose. Besides being a cost-saving option, scrap reduces industrial waste. For aluminum extrusion framing, recycled scrap offers a sustainable choice. Scrap is an environment-friendly option in aluminum extrusion.

Master alloys

Master alloys aid in refining the aluminum before extrusion. These mixtures assure control over the properties of the final product. An aluminum extrusion heat sink, for example, relies on the thermal characteristics that these alloys provide. Consequently, extrusion quality improves.

Extrusion Dies and Tooling!

Flat Dies

In aluminum extrusion, flat dies play a critical role. Shaping custom extrusions aluminum, these dies cater to a broad spectrum of designs. Steel, with a hardness of 56 to 62 Rockwell C makes up the flat die. They offer robustness and durability. Moreover, an expected die life is around 60,000 meters of extruded profile.

Hollow Dies

Hollow dies, essential in creating extrusion aluminum profiles, offer more complex designs. Aluminum channels, tubing, and other large aluminum extrusions owe their shape to these dies.

Remember, the die design impacts the flow of the aluminum, with a typical extrusion speed of 30 to 75’ per minute.

Semi-hollow Dies

Creating a product in-between solid and truly hollow? Semi-hollow dies come into action. Enabling small aluminum extrusions, the die design tends to suit well for standard aluminum extrusion profiles. The extrusion pressure may range between 500 to 10,000 tons, depending on the profile and alloy.

Shape Dies

From standard aluminum extrusions to customized ones, shape dies mold them all. Ideal for t track aluminum extrusion, their role spans across industries. The die maintenance cycle is significant. After 15,000 meters, a light polish is often necessary to maintain quality.

Porthole Dies

When dealing with t-slotted aluminum extrusion or triangle aluminum extrusion, porthole dies become instrumental. Crucial in manufacturing the 1530 aluminum extrusion or the 1×2 aluminum extrusion, they manage multiple intricate profiles. They can handle high extrusion temperatures, ranging from 350°C to 500°C.

Die rings

In aluminum extrusion dies, die rings are crucial. Steel-made, they withstand high pressures and temperatures. You find them in different sizes, designed for various extrusion profiles.

Aluminum extrusion alloys often pass through these rings. Durability is their key feature, making them vital for long-term production cycles.

Die inserts

For 2020 aluminum extrusions, die inserts matter. The steel construction ensures sturdiness. Their design aligns with the profile shape. To get a specific cross-sectional product, die inserts are a necessity. With precise machining, they give you quality extrusions every time.

Backers

Look into the heart of an aluminum extrusion design competition scholarship and you’ll find backers. Backers support die assemblies and distribute pressure evenly. They are made of H13 steel, built to last. In the aluminum extrusion catalog, backers have a prominent place.

Bolsters

Often used in 8020 aluminum extrusions, they bear the brunt of the extrusion pressure. These parts secure the die assembly in the press. Bolsters contribute to precise, accurate extrusions. Don’t overlook their role in an aluminum extrusion 3d printer.

Mandrels

In a 40×40 aluminum extrusion, mandrels work magic. They form internal voids in extrusions. Mandrels are steel, designed to withstand extreme pressure. Some are solid, others hollow.

All contribute to the final profile shape. In aluminum extrusion companies in the USA, mandrels are the unsung heroes.

Quality Control in Aluminum Extrusion!

Pic 4

Dimensional inspection

In an aluminum extrusion factory, inspecting dimensions is vital. Here, workers use instruments such as calipers, micrometers, and gauges. Exact measurements are critical to ensure product conformity. Variations can cause serious problems.

Remember, too wide, too short, or too thin can lead to assembly issues. The aluminum extrusion frame kits must match specifications. Consistent checking during the production process guarantees precision.

Surface inspection

The surface of aluminum extrusion parts undergoes close examination. Errors such as pockmarks or blisters can affect the final product’s performance. Each part is examined under intense lighting. Special attention is paid to color uniformity and finish texture. The aluminum extrusion line must produce flawless components.

Mechanical tests

Understanding the aluminum extrusion strength calculator is essential. Mechanical tests measure hardness, tensile strength, and elongation rates. For safety, an aluminum extrusion press of appropriate size is utilized. Aluminum should resist deformation under pressure.

Tests run in a simulated environment mimic real-life conditions. Quality assurance teams use these results to verify product robustness.

Chemical analysis

In aluminum extrusion processing, chemical composition matters. Analysts perform in-depth chemical checks. Labs use spectroscopy to identify impurities in the aluminum.

A wrong alloy mixture could ignite an aluminum extrusion plant fire. Thus, achieving the right mix is crucial. Precise control over alloy composition assures reliable, high-quality aluminum extrusion products.

Hardness test

Ensuring top-tier products involves testing the hardness. In aluminum extrusion tolerances, Brinell Hardness Test (BHT) takes center stage. A machine presses a steel ball into the extrusion.

The measurement of the dent gauges hardness. A lower BHT score indicates softer metal. Each hardness level has specific applications in the industry. A correct hardness measurement ensures reliable use and durability.

Conductivity test

Conductivity testing plays a pivotal role. This test checks the ability of an aluminum extrusion workbench kit to conduct electric current. A higher conductivity score means better current passage. Accurate conductivity results ensure safety and efficiency in electrical applications.

For instance, high conductivity makes aluminum ideal for electrical wiring systems.

Ultrasonic testing

Next comes ultrasonic testing, a non-destructive test method. Through this, aluminum extrusions for screen enclosures undergo examination. Technicians use sound waves above human hearing range. They watch for reflections indicating defects.

A smooth echo means sound waves pass through the material unhindered. Successful ultrasonic tests reflect premium-quality aluminum.

Radiographic inspection

The radiographic inspection unveils internal irregularities. In the inspection of aluminum heatsink extrusion, X-rays or gamma rays get applied.

These rays expose defects hidden to the naked eye, for instance, bubbles or inclusions inside the metal. Radiographic inspection, hence, promotes optimal performance of heatsink extrusions.

Troubleshooting Common Problems in Aluminum Extrusion!

– Die lines

Die lines mark a common problem. Raw material enters a metal plate or die, shaping into the profile. Die lines happen when dies wear out. Your diy aluminum extrusion workbench can help in inspecting die lines. Regular maintenance on dies is crucial to avoid lines.

– Piping defects

Piping defects often plague the aluminum extrusion process. In piping, metal flows unevenly around the bearing area, causing defects. A common tool, faztek aluminum extrusion, can fix this issue. Pro tip – ensure uniform pressure during extrusion.

– Surface cracks

Surface cracks form in the cooling stage of extrusion. Temperature shifts create these cracks. Using home depot aluminum extrusion tools control the cooling rate to avoid surface cracks. Keeping track of temperature changes is vital.

– Incomplete fill

Sometimes, the aluminum does not fill the entire die. It results in an incomplete fill. When asking how are aluminum extrusions made, improper fill often comes up. High viscosity of the aluminum, too low temperature, or an unfit billet can cause this problem. Use precise control for flawless results.

– Internal tears

High-speed extrusion can lead to internal tears. These tears compromise the strength of the aluminum extrusion. For instance, how strong is 2020 aluminum extrusion, is a frequent question. It comes down to how well the internal structure is maintained. Slow down the process to prevent these tears. Using right extrusion speed is critical.

– Surface scratching

In the aluminum extrusion process, surface scratching is a common issue. Especially seen with 1 1 8 od aluminum extrusions and 1 2” double angle aluminum extrusion. These scratches could be due to improper handling or contact with hard surfaces.

High-grade protective materials should guard aluminum parts during handling and transportation. Avoiding any contact with sharp objects is key. The appearance of finished products improves with such preventive measures.

– Oxidation

Aluminum extrusions, specifically 10 series aluminum extrusion dimensions and 1030 aluminum extrusion, can suffer from oxidation. It’s a chemical reaction with oxygen causing a dull finish on the aluminum. An anti-oxidation coating can protect the extrusion surfaces. Proper storage in low-humidity environments also helps prevent oxidation.

– Weld lines

Weld lines are visible seams that occur in extruded aluminum, notably in 1.5 aluminum extrusion and 15 series aluminum extrusion dimensions. These lines form when separate streams of aluminum merge in the die. To minimize weld lines, proper die design and controlled extrusion speed are crucial. In the end, maintaining consistent quality control is paramount in aluminum extrusion production.

Applications of Aluminum Extrusion!

Automobile parts

In auto manufacturing, 15180 aluminum extrusion makes light, robust engine components. Furthermore, crash structures benefit from 1×3 aluminum extrusion.

That’s for its high-strength capacity. Besides, 1545 aluminum extrusion contributes to elegant auto interiors. Suspension parts employ 15×15 aluminum extrusion for added stiffness.

Aircraft frames

In the aviation industry, 2020 t slot aluminum extrusion is crucial for strong airframes. The 2 x 2 aluminum extrusion helps in making light, durable fuselage. Besides, 2020 v slot aluminum extrusion aids in constructing airplane cabins. 2020 series aluminum extrusion contributes to sturdy aircraft wings.

Solar panels

The energy sector utilizes 2020 aluminum extrusion profile in solar panel frames. To add, 15mm aluminum extrusion is crucial for panel housing. Also, 2 x 2 aluminum extrusion ensures structural stability. 2020 aluminum extrusion v-slot helps with panel ventilation.

Heat sinks

Aluminum extrusion in heat sinks is critical. When using 2024 t3511 aluminum extrusion, sinks become efficient. Heat sinks are crucial in computers.

Aluminum’s high thermal conductivity makes it perfect. For example, a CPU heat sink could have dimensions of 3.93×2.76×0.59”. Extruded aluminum ensures heat disperses fast, keeping machines cool.

Rail tracks

For rail tracks, aluminum extrusion shines. A standard example is a 20×40 aluminum extrusion in railway tracks. Aluminum’s light weight helps keep trains moving smoothly. Additionally, a typical rail might be 60’ in length, providing durability and structural support.

Furniture frames

When crafting furniture, professionals opt for aluminum extrusion. Specifically, a 20×20 aluminum extrusion cad model aids designers. A dining table, perhaps, might measure 72x36x30”. Extruded aluminum provides stylish, lightweight, and sturdy frames.

Architectural profiles

In building profiles, aluminum extrusion shows versatility. For example, 2×4 aluminum extrusion helps architects design durable structures. A standard window frame might be 36×48”, and aluminum extrusion guarantees durability with style.

Machine components

In machine parts, aluminum extrusion is pivotal. 3 4 Aluminum extrusion ensures machine efficiency. For instance, a machine’s body frame might measure 60x60x40”. Aluminum extrusion offers robust, light, and resilient components, improving the machine’s lifespan and performance.

Designing for Aluminum Extrusion!

» Material selection

The secret to sturdy structures lies in the material choice. Aluminum Extrusion stands as a preferred option. Start with the 40mm t-slot aluminum extrusion.

Crafted to perfection, the robust extrusion guarantees strength and durability. Indeed, every inch of the 40mm x 40mm aluminum extrusion screams high quality.

Imagine, then, how dependable the 40×160 aluminum extrusion is. Trust in its potential, and witness an impressive transformation in the assembly process.

» Geometry consideration

All the 3030 extrusion aluminum and 30mm aluminum extrusion pieces should fit together seamlessly. Yet, it’s not enough to just have the 30 x 30 aluminum extrusion; knowing the 3030 aluminum extrusion dimensions is equally critical. Indeed, measurements play a vital role. A slight miscalculation can lead to severe structural issues, causing problems down the line.

» Wall thickness

Here’s the deal with 3 8” double angle aluminum extrusion. A solid wall ensures stability. Now, imagine that with a 3×3 aluminum extrusion. Firmness increases manifold. Moreover, using a 40-80 aluminum extrusion with an optimized wall thickness enhances the assembly’s overall sturdiness. The point here is: Thick walls equal stability. Don’t ignore them!

» Corners & radii

Be sharp about corners. Proper angles can make or break a design. Pay attention to the 45° aluminum extrusion. Its distinctive angle gives a sharp edge to your structure.

Moreover, when combined with the 30 series aluminum extrusion, the results are remarkable. Equally important are the 40 x 20 aluminum extrusion and the 40120 aluminum extrusion. Remember, every angle counts.

» Draft angles

Consider the draft angles. They prove crucial for the 4040 aluminum extrusion t-slot. Besides, when it comes to the 4080 aluminum extrusion black, draft angles facilitate easier extrusion.

Here’s a tip: Use a 40mm aluminum extrusion. Why? Its draft angles provide increased stability. The same goes for 40×20 aluminum extrusion and 40×80 aluminum extrusion. Draft angles matter, so take note!

» Symmetry

In 45 series aluminum extrusion, balance matters. Center features to cut back on warping. A die with mirrored parts prevents bending. Also, symmetrical extrusion reduces thermal distortion.

Better cooling equals greater stability. The end product displays excellent flatness. In essence, symmetry creates optimal product quality. Expect reduced wastage with well-designed, balanced extrusions.

» Tolerance limits

Careful setting of dimensions is critical in 6061 aluminum extrusion. Tight tolerances ensure an exact fit. A gap of 0.2 mm may be acceptable. Too much variation could affect assembly.

Exact measurements avoid slippage or lose of parts. Firmly set tolerance limits ensure product quality. In the end, precise dimensions contribute to optimal functionality.

» Surface finish

A shiny or dull finish affects the 60° aluminum extrusion appearance. Brushing enhances the metal’s visual appeal. Anodizing prevents surface oxidation. Extrusions can also be powder coated. Each method provides a unique texture. In fact, the surface finish impacts more than looks. It extends an extrusion’s lifespan, boosting overall value.

» Hollow sections

7075 aluminum extrusion often features hollow spaces. Tubes, for instance, are common. The 8020 slotted aluminum extrusions also use this design. Hollow structures reduce weight.

They provide strength without extra material. Lighter extrusions cut down on transport costs. Moreover, hollow designs can enhance structural rigidity. Hence, hollow sections offer both functional and economic benefits.

» Extrusion ratio

The extrusion ratio matters in 80160 aluminum extrusion. It’s the cross-sectional area before and after. For example, a ratio of 10:1 means high pressure. High ratios require more energy.

They can also result in stronger, denser products. Low ratios save energy. They result in less dense, more flexible extrusions. Therefore, consider the desired properties when determining the extrusion ratio.

Understanding T-slot Aluminum Extrusions!

What is a T-slot Extrusion?

In the field of Aluminum Extrusion, a T-slot Extrusion, also known as 8020 t-slot aluminum extrusion, is an integral part. This type of profile gets its name from the T-shaped slots.

Manufacturers craft these to allow the addition of brackets, nuts, and components. Easily adjustable, these elements provide seamless connections in design.

Used in machine frames, conveyors, workstations, and other structural applications, T-slot extrusions promote efficiency. With high strength, durability, and resilience, T-slot extrusions are a favorite for engineers and builders. Expertly designed to handle stress, these components offer remarkable performance.

Comparing Aluminum Extrusion with Other Materials!

| Criteria | Strength (MPa) | Weight (g/cm^3) | Thermal Conductivity (W/mK) | Corrosion Resistance | Cost ($/kg) | Machinability |

| Aluminum Extrusion | 310 | 2.7 | 205 | High | 1.85 | Easy |

| Steel | 500 | 7.8 | 54 | Medium | 0.80 | Moderate |

| Plastic | 60 | 1.4 | 0.2 | High | 1.50 | Easy |

| Wood | 40 | 0.6 | 0.1 | Low | 0.20 | Easy |

| Copper | 210 | 8.9 | 401 | High | 6.00 | Moderate |

| Glass | 50 | 2.5 | 1.1 | High | 2.50 | Hard |

| Concrete | 30 | 2.4 | 1.7 | Medium | 0.05 | Hard |

| Brass | 360 | 8.4 | 109 | High | 3.70 | Moderate |

| Titanium | 880 | 4.5 | 21.9 | Very High | 11.00 | Hard |

| Rubber | 15 | 1.2 | 0.2 | Medium | 2.20 | Easy |

| Ceramics | 345 | 3.0 | 1.5 | Very High | 3.00 | Hard |

Table on Comparing Aluminum Extrusion with Other Materials!

Conclusion

Aluminum Extrusion holds vast potential. After exploring its process, applications, and troubleshooting, a clearer understanding emerges. To take this knowledge further, delve deeper at KDMFAB. Keep learning, keep growing, and become a leader in this dynamic field of Aluminum Extrusion.