In today’s fast-paced manufacturing world, speed and efficiency are essential if you want to stay competitive. High-speed stamping is a technology that has revolutionized the manufacturing industry, allowing for faster and more efficient production of high-quality parts. This article will explore the processes, uses, pros, and cons of high-speed stamping technology.

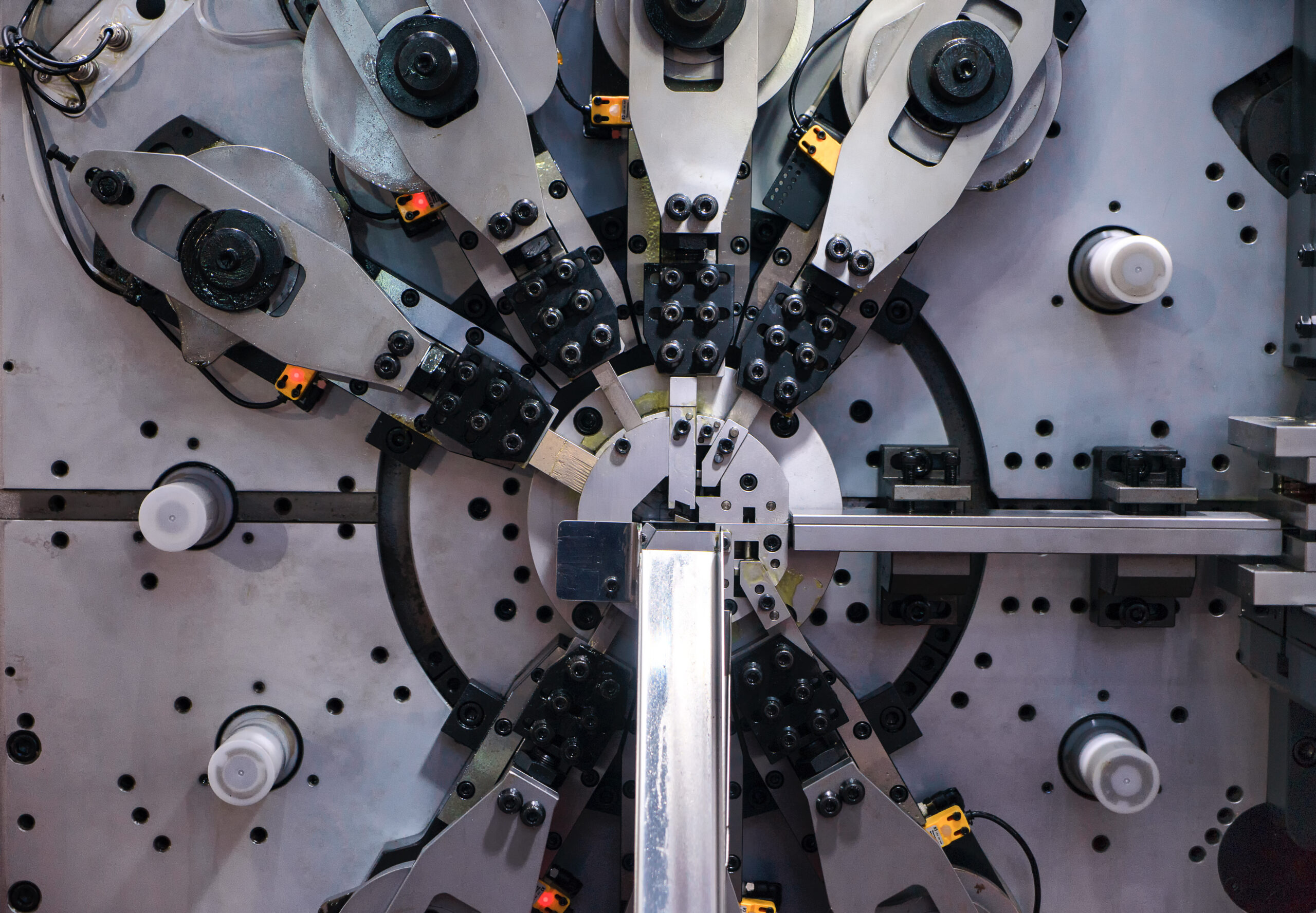

High-speed stamping is a process that involves punching, cutting, or shaping metal parts at high speeds. This technology has become an essential part of modern manufacturing, providing numerous benefits to companies that adopt it. Using high-speed stamping machines has transformed the industry by enabling faster production and reducing costs while maintaining high accuracy and consistency.

High-Speed Stamping Processes

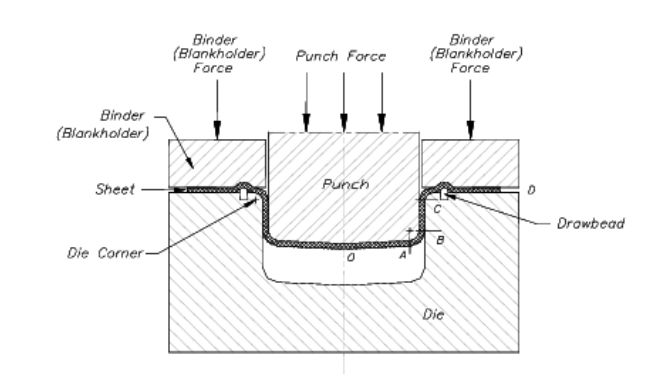

Stamping is a manufacturing process that involves shaping, cutting, and forming materials into precise and specific shapes using a press machine and a die. The material, which can range from metal sheets to plastic or rubber, is placed between the die and the press machine, and pressure is applied to deform the material into the desired shape.

In the high-speed stamping process, you use a stamping press capable of punching, cutting, or shaping metal parts at a higher rate than traditional stamping. The process typically involves feeding a metal strip into the press, which cuts or shapes the metal parts using a die.

High-speed stamping machines can operate at rates of up to 1,500 strokes per minute, making them ideal for high-volume production.

1. Components of High-Speed Stamping Press

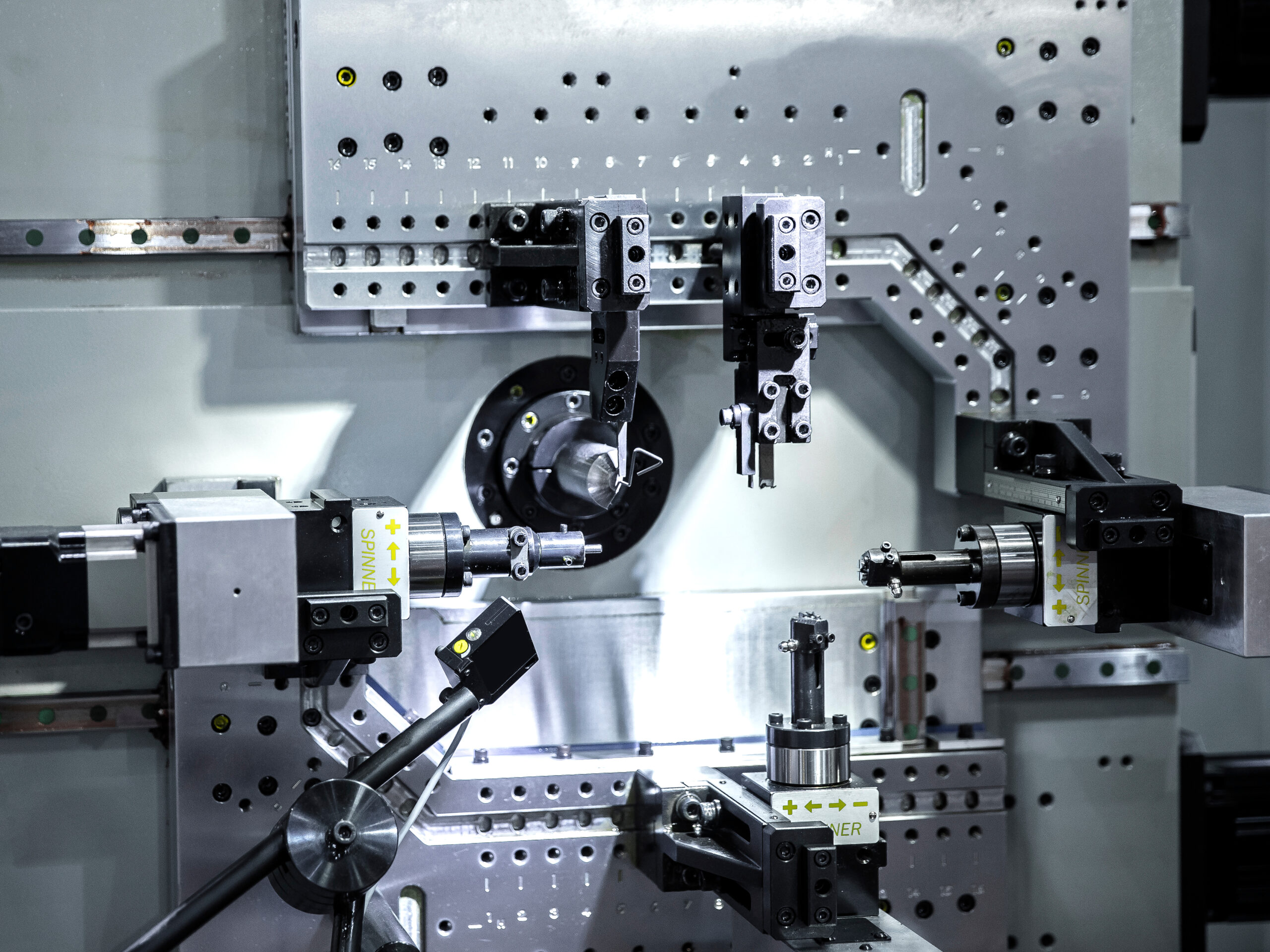

A high-speed stamping press has several components that work together to achieve high-speed production. These include a feeder, a die, a press, and a control system. The feeder feeds the metal strip into the press, and the die shapes or cuts the metal into the desired shape. The press applies pressure to the die, and the control system ensures the process runs smoothly.

2. Types of High-Speed Stamping Press

There are two main types of high-speed stamping technology: mechanical and hydraulic

| Mechanical High-Speed Stamping | Hydraulic High-Speed Stamping |

| Uses a mechanical drive to power the press. | Uses hydraulic power to operate the machinery. |

| Faster and more precise. | Slower and less precise. |

| Mechanical High-Speed Stamping machines are more expensive. | Hydraulic High-Speed Stamping Machines are less expensive than their mechanical counterparts. |

| Require more maintenance. | Require less maintenance. |

High-Speed Stamping Applications

High-speed stamping has many uses in modern manufacturing. Some of the most common applications of high-speed stamping include

- Automotive Industry: You can produce various components of automobiles, such as engine components, structural parts, and body panels, through high-speed stamping.

- Consumer Electronics: You’ll notice that small metal parts, such as brackets and connectors, are often manufactured through high-speed stamping processes.

- Aerospace Industry: The aerospace industry utilizes high-speed stamping to produce components that meet strict quality and performance standards, including aircraft engine parts, turbine blades, and landing gear components.

- Medical Industry: As surgical instruments and implants require high precision in their designs, they are often made through high-speed stamping processes.

- Packaging Industry: High-speed stamping is also used to produce a variety of packaging components, including cans, bottle caps, and other metal containers.

Overall, the speed, efficiency, and precision of high-speed stamping make it ideal to produce components and products of diverse functionalities.

High-Speed Stamping vs. Traditional Stamping Processes

The differences between high-speed stamping and traditional stamping are as follows:

| High-Speed Stamping | Traditional Stamping |

| Operates at a higher speed | Operates at a slower speed |

| Requires specialized equipment and tools | Uses standard equipment and tools |

| Produce more finished products in less time | Produces fewer finished products in more time |

| Can work with a broader range of materials | Limited in the range of materials it can work with |

| Produces parts with more consistent quality and accuracy | May produce parts with lower consistency and accuracy |

| Requires higher initial investment costs | Has lower initial investment costs |

High-Speed Stamping Pros and Cons

Here is a brief comparison of high-speed stamping’s pros and cons:

Pros

The advantages of the technique are as follows:

1. Increased Productivity and Efficiency

High-speed stamping offers you significant advantages in terms of productivity and efficiency. The stamping speed increases output, resulting in a faster turnaround time and lower manufacturing costs. So, it can reduce material waste, improve product quality, and enhance your production efficiency.

2. Cost Savings and Faster Time to Market

Because of the speed at which high-speed stamping presses can operate, manufacturers can save on labor costs and materials. Additionally, the faster production time allows you to get products to market more quickly, giving you a competitive edge and potentially increasing profitability.

3. Consistency and Precision in Stamping

High-speed stamping technology enables more precise and consistent stamping, which is critical in many industries, particularly the automotive and aerospace industries. With it, you can achieve high precision, consistency, and repeatability, resulting in a higher-quality end product.

4. Ability to Work With Various Materials

You can use high-speed stamping presses with various materials, including metals, plastics, and composites. This flexibility allows manufacturers to produce various products, from simple metal components to complex plastic parts.

5. Environmental Benefits

Because high-speed stamping presses can operate at such high speeds, they use less energy and generate less waste than traditional stamping presses. This makes them a more environmentally friendly manufacturing process.

Cons

The limitations of the technique include the following:

1. Initial Investment Costs

One of the most significant drawbacks of high-speed stamping technology is the investment you require. High-speed stamping presses are more expensive than traditional ones, and upgrading or retrofitting existing equipment can also be significant.

However, the increased productivity and efficiency of high-speed stamping can offset these costs over time.

2. Limited Flexibility in Stamping Design

Another disadvantage of high-speed stamping is that it can be less flexible than traditional stamping processes regarding design changes. The presses used in the process are designed for high-volume production runs of a single design, so changing the stamping process can be time-consuming and costly.

3. Potential Safety Concerns

High-speed stamping presses can be dangerous if not operated correctly. The high speeds at which they operate can create a significant amount of force. This poses a significant risk to your workers if safety protocols are not followed.

4. Need for Specialized Training

Because of the potential safety concerns associated with high-speed stamping, specialized training is required for operators. This training can be time-consuming and costly, but it is essential to make sure your workers are safe, and your products are produced uniformly.

Maintenance of High-Speed Stamping Presses

You have to maintain your high-speed stamping equipment to ensure its optimal performance and longevity. Some standard maintenance requirements include the following:

- Lubrication of moving parts

- Inspection and replacement of worn parts

- Cleaning of dies and press components

- Calibration of sensors and other equipment

Regular maintenance can help prevent breakdowns and downtime, ensuring that you can continue to produce parts efficiently and reliably. You should also have a plan for addressing common issues and troubleshooting problems that may arise during operation.

Factors to Consider When Choosing High-Speed Stamping

When considering high-speed stamping as a manufacturing process, there are several factors to remember. Here are some essential ones:

1. The Required Production Volume

High-speed stamping can be an excellent choice for large production runs but may not be cost-effective for smaller runs. So, you must consider your production volume to determine your run’s cost-efficiency.

2. Stamping Complexity and Design Considerations

High-speed stamping best suits simple, repetitive shapes. If your stamping needs are more complex, you may need to consider other manufacturing processes. Similarly, not all materials can be stamped with high-speed stamping processes.

3. Available Budget and Resources

High-speed stamping presses can be expensive, and specialized training and equipment may be required. Make sure you have the budget and resources necessary to implement high-speed stamping before making the decision to switch to this manufacturing process.

Endnote

In conclusion, high-speed stamping can significantly benefit your business’s productivity, efficiency, and profitability. By providing faster production times, increased accuracy and precision, and diverse production options, high-speed stamping can help your business stay competitive in today’s fast-paced marketplace.

However, while stamping technology’s speed and efficiency can be advantageous, you must also consider the initial investment cost and limited design flexibility.

Ensure you carefully evaluate your production volume requirements, material compatibility, stamping complexity, and available budget and resources.

If you do not want to invest in a press yourself, you can always contact us for your metal stamping needs. Where to buy high-speed stamping press? Just contact KDMFAB.

Metal Stamping Parts – Source: KDMSteel