Rapid prototype casting is a handy innovation in turning ideas into prototypes. Overall, this article covers the fascinating advantages and materials of rapid prototype casting.

What is Rapid Prototype Casting?

In general, rapid prototyping uses 3D printing to turn digital designs into prototypes. In any case, the process creates a mold as the template for the prototype.

You can pour the molten material into the mold to cool & solidify. Overall, rapid prototype casting is a quick approach to materializing ideas into prototypes.

The Rapid Prototype Casting Process

This part covers the rapid prototype casting process. In any case, it explains the steps in transforming your innovative concept into a prototype. Read on to understand how you can implement this process and ensure excellent results for your projects.

Conceptualization & Design

First, the rapid prototype casting process begins with the spur of your innovative idea. In any case, you start the conceptualization and design stage. Here, your vision takes shape on paper. However, consider your prototype’s function & form.

3D Modeling

The second step in the rapid prototype casting process is 3D modeling. Here, the 3D modeling tech allows you to scrutinize your prototype. In other words, 3D innovation is vital for rapid prototyping investment casting.

Material Selection

In any case, material selection is a critical point in the third rapid prototype casting stage. In general, you can delve into the choices shaping your prototype’s features. Overall, evaluate the properties to ensure they align with your design needs. In the meantime, cost implications are critical, and environmental impact is another concern.

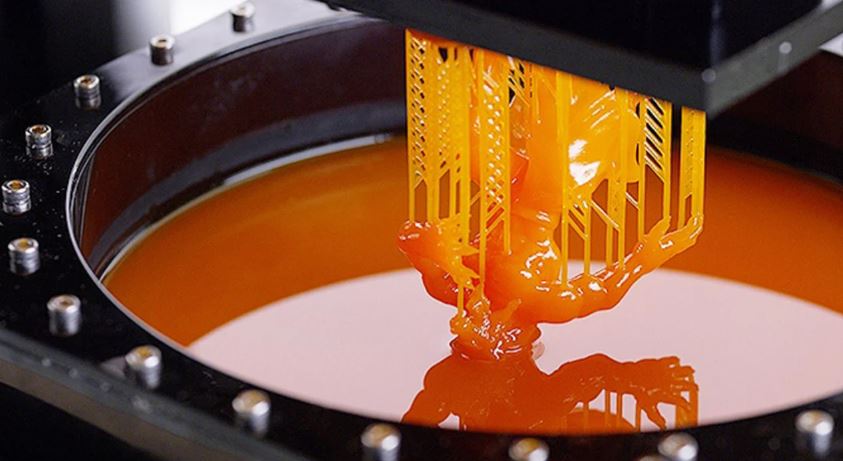

3D Printing the Model

In simple terms, your vision takes a tangible form in the 3D printer layer by layer. Overall, the 3D transformative tech propels realizing your innovative ideas and mastering innovation through investment casting rapid prototyping.

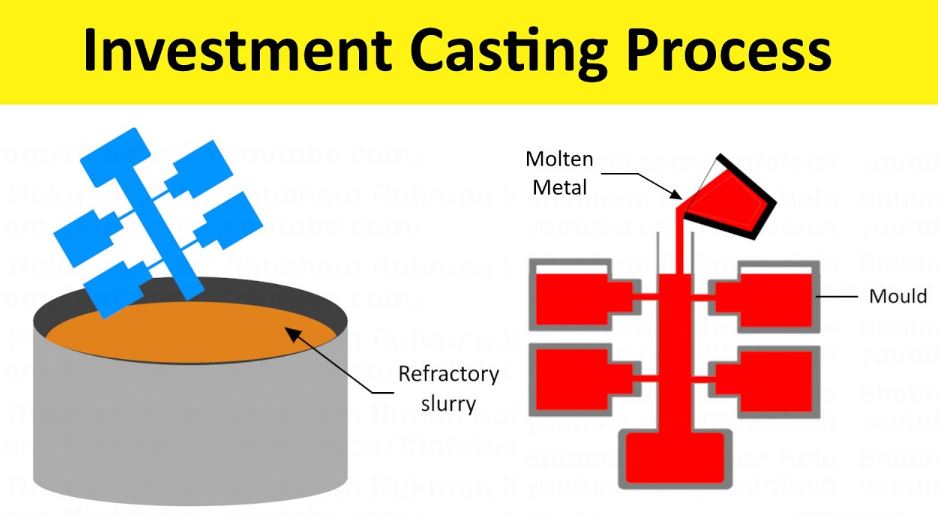

Mold Creation

In general, creating the mold is a meticulous task. Most importantly, it involves crafting a template that will define the shape of your prototype. Hence, the mold creation process ensures that the molten material takes the desired form.

For that reason, skilled craftsmanship is essential to replicate detail. Simply put, the blueprint is a critical element in rapid prototype casting. In any case, mold creation marks a significant milestone in bringing your innovative concept to life.

Casting the Prototype

Overall, casting the prototype brings your mold design to life in rapid prototype casting. In general, this step involves pouring molten material into the mold to flow into the mold and capture the design. Thus, the process requires precision since the casting quality influences the product. Next, the mold cools & solidifies its structure.

Mold Removal

In any case, this step requires attention to detail for your cast prototype to remain intact during removal. Here, skilled craftsmanship is essential for realizing your ideas and mastering innovation through rapid prototype casting.

Selecting the Right Rapid Prototype Casting Material

In general, the rapid prototype casting material you select impacts the performance and characteristics of your prototype. Simply put, your decision influences the following steps. Thus, ensure that the prototype aligns with your design & functional needs.

Understand the End Use

First, understanding the application is vital in selecting the suitable rapid prototype casting material. Overall, consider the specific purpose your prototype will serve. In general, these factors guide in mastering innovation through rapid prototype casting.

Evaluate Material Properties

Overall, you must evaluate the rapid prototype casting material’s properties. In simple words, this step involves examining the characteristics to match them with your needs. For instance, consider heat resistance, flexibility, durability, and strength.

Level of Detail

In any case, determining the level of detail required is crucial when selecting the suitable rapid prototype casting material. In general, this consideration ensures your prototype’s fidelity and showcases creative vision through rapid prototype casting.

Post-Processing Needs

Meanwhile, post-processing considerations are critical when selecting the rapid prototype casting material. In general, it is vital in the final touches on your masterpiece to achieve the desired look. Thus, consider whether the prototype will require smoothing, polishing, and painting.

Cost Implications

In the meantime, evaluate the cost and expenses related to post-processing it. In any case, this consideration ensures that your rapid prototype casting project remains cost-effective while delivering exceptional results.

Casting Technique

Overall, the casting tech is critical when selecting the rapid prototype casting material. In general, it reflects selecting the right tool for the project. Therefore, consider casting methods like investment, sand, or vacuum.

In any case, some materials may perform better with specific methods. Thus, the casting tech allows you to optimize the production process and achieve quality results.

Environmental Impact

In general, assessing the environmental impact is critical in selecting the rapid prototype casting material. For that reason, consider the sustainability of the material. Does it have a lower carbon footprint? In any case, this aspect ensures your rapid prototype casting project is innovative and environmentally conscious.

Test for Functionality

Overall, testing for functionality is critical in selecting the suitable rapid prototype casting material. Thus, consider the specific functions your prototype needs to fulfill. Thus, perform functional tests to validate the material’s suitability.

Rapid Prototype Casting Materials

In general, rapid prototype casting allows you to explore various material options. In any case, suitable materials make a difference in the medical industries, automotive, and aerospace. Overall, this section covers rapid prototype casting materials.

Brass

Overall, brass is a versatile material for rapid prototype casting since it provides strength & corrosion resistance. In the meantime, it offers machinability & suits intricate designs. Besides, its durability & corrosion resistance suit diverse settings.

Generally, rapid prototype casting explores the possibilities of using brass to create complex and detailed prototypes. Meanwhile, its malleability allows for intricate shapes and fine details. Above all, it can maintain its form & finish in diverse settings.

Steel

Steel is a reliable material in rapid prototype casting. In any case, its strength & durability suit industrial machinery components and automotive parts. In general, its corrosion resistance & high temperatures ensure longevity & performance.

Bronze

Bronze is a versatile material in rapid prototype casting for its unique strength, corrosion resistance, and aesthetic appeal. Thus, it can deliver functional & elegant prototypes with a distinctive blend of form and function.

Titanium

Titanium is a remarkable material in rapid prototype casting. In other words, it features corrosion resistance, low density, and unique strength. Simply put, titanium stands out for its outstanding characteristics in rapid prototype casting applications. Thus, it is typical in aerospace and medical industries due to its biocompatibility.

Mild Steel

Mild steel offers ease of fabrication, affordability, and strength. Thus, the material offers durability and cost-effectiveness. In any case, it is typical in applications such as automotive parts and construction components since it can withstand stress & pressure.

Galvanized

Overall, galvanized steel materials have a considerable prevalence in rapid prototype casting. The manufacturing process involves coating steel with a zinc layer for durability. In any case, it ensures durability and environmental resistance in rapid prototype casting.

Aluminum

In general, aluminum is versatile in rapid prototype casting since it is lightweight and corrosion-resistant. Above all, aluminum provides a reliable solution in rapid prototype casting for a perfect balance of strength and weight.

Stainless Steel

Stainless steel is a remarkable choice for rapid prototype casting due to its exceptional properties. In any case, its corrosion, heat, and wear resistance make it a standout material for various uses. Stainless steel offers versatility in rapid prototype casting.

Rapid Prototype Casting Technologies & Techniques

Rapid prototype casting technologies and techniques are where innovation meets precision. In general, explore technologies like Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA).

In any case, Stereolithography (SLA) is a pivotal innovation in rapid prototype casting technologies. Overall, it is the precision tool for sculpting your design layer by layer. In general, a UV laser solidifies liquid resin to create intricate 3D models.

On the other hand, Selective Laser Sintering (SLS) is a formidable technology in rapid prototype casting. In any case, SLS opens up possibilities for your rapid prototype casting projects through innovation, durability, and material versatility.

Advantages of Rapid Prototype Casting

Rapid prototype casting allows you to test and refine diverse designs. Meanwhile, you can create complex and intricate parts with precision. This section covers the advantages you will get from rapid prototype casting products.

Speed

Rapid prototype casting speed enables you to create physical objects from concepts in record time. Overall, traditional manufacturing methods cannot match its speed. You can iterate designs with reduced development cycles. In any case, speed is critical in a competitive market, and rapid prototype casting allows you to meet tight deadlines.

Cost-Efficiency

Rapid prototype casting stands out for its cost-efficiency since it is different from traditional manufacturing processes that feature hefty setup costs.

In general, rapid prototype casting minimizes the initial expenses. Above all, rapid prototype casting offers an affordable solution without compromising quality.

Design Flexibility

Design flexibility is critical in rapid prototype casting since it offers diverse project possibilities. In any case, rapid prototype casting enables you to iterate prototypes fast.

Improved Accuracy

In general, improved accuracy is a notable advantage of rapid prototype casting. In addition, the casting process minimizes the errors for aerospace, automotive, and healthcare products. Above all, rapid prototype casting creates prototypes.

Material Variety

Rapid prototype casting offers various material options to suit diverse project requirements. Most importantly, it can suit a project that demands the strength of metals like aluminum & steel or needs the flexibility and precision of polymers.

Functional Testing

Above all, functional testing in rapid prototype casting involves subjecting the casted component to various tests and evaluations to assess its functionality and reliability. Overall, it guarantees the reliability & performance of the rapid prototype casting.

Customization

In general, customization in rapid prototype casting allows you to tailor your prototypes to your specific needs. Overall, rapid prototype casting offers customization options for specialized material properties and unique geometries.

Reduced Waste

In general, the rapid prototype casting tech minimizes more material wastage than traditional casting techniques. In any case, rapid prototype casting ensures you use suitable material with minimal scrap.

Rapid Prototype Casting Applications

Overall, rapid prototype casting has uses in diverse settings since it creates intricate prototypes. In any case, this section covers diverse rapid prototype casting uses.

Automotive

In simple words, rapid prototype casting is an advanced casting method that enables manufacturers to accelerate product development. Overall, rapid prototype casting provides a cost-effective solution for automotive products.

Aerospace & Aviation

In any case, Rapid prototype casting is a cutting-edge casting method that revolutionizes aircraft manufacturing. Overall, rapid prototype casting provides an efficient approach to meeting manufacturing standards in aerospace & aviation.

Medical & Healthcare

Meanwhile, rapid prototype casting has transformed equipment in medicine and healthcare. In general, it is an advanced casting tech that provides precision & speed.

In any case, rapid prototype casting provides benefits for specialized components, diagnostic equipment, and surgical instruments. For instance, it can craft intricate implants with rapid prototype aluminum casting.

In the meantime, it can leverage rapid prototyping and digital sand casting services for forefront innovation in the healthcare industry. Furthermore, investment casting rapid prototyping allows for precise and complex parts.

Consumer Electronics

Overall, rapid prototype casting is emerging in consumer electronics for the swift development of intricate components. In other words, it can create sleek and durable casings with rapid prototype aluminum casting. In the meantime, it can refine the internals of your gadgets with rapid prototype sand castings.

Thus, the versatility of rapid prototyping investment casting allows you to experiment with various designs to meet the demands. Moreover, rapid prototyping and digital sand casting services can iterate your product designs for functionality & style.

Industrial Machinery

In any case, rapid prototype casting enhances production in industrial machinery. In general, it can design complex components and robust parts. Overall, investment casting rapid prototyping enables you to create accurate machinery parts easily.

For that reason, you can experiment with designs & materials to optimize performance and durability through rapid prototype aluminum casting. In the meantime, rapid prototyping investment casting ensures that your machinery components are reliable & cost-effective. In addition, it eliminates tooling and streamlines manufacturing.

Architecture & Construction

In general, rapid prototype casting tech provides an innovative approach for casting rapid prototyping & investment casting rapid prototyping in architecture. In any case, it has transformed production processes in construction.

Simply put, rapid prototype aluminum casting & rapid prototype sand castings create intricate architectural components & construction elements. Thus, their precision & versatility of rapid prototyping investment casting allow architects to diversify designs.

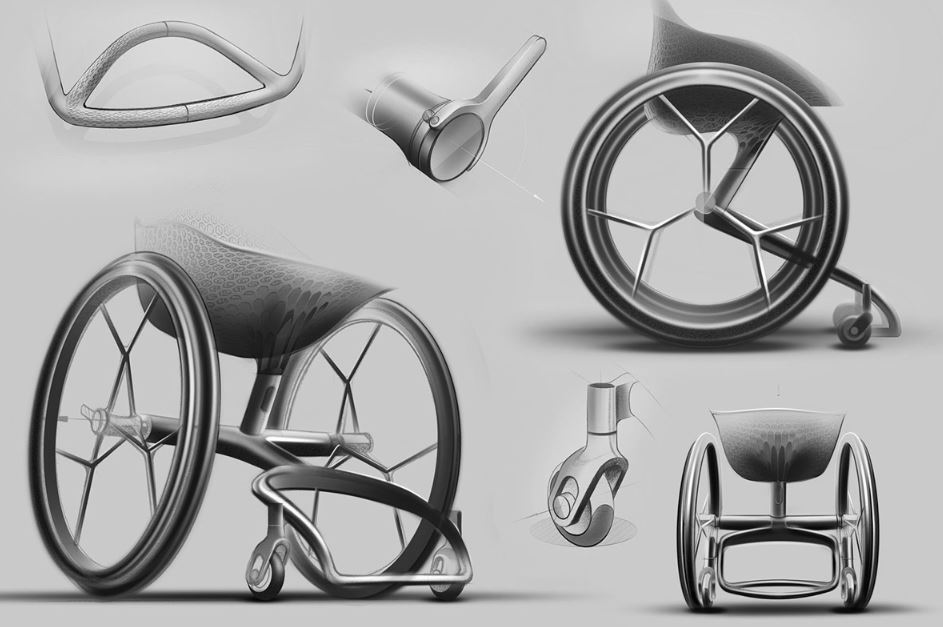

Jewelry Design

Above all, rapid prototype casting has ushered in a new era of creativity and precision in jewelry. Overall, this tech combines jewelry crafting with rapid prototyping efficiency for exceptional prototypes. In any case, jewelry designers use rapid prototype aluminum casting & rapid prototype sand castings to craft unique pieces.

In general, the precision of rapid prototyping investment casting boosts customization. Overall, rapid prototype casting brings your vision to life with a blend of art.

Art & Sculpture

Besides, rapid prototype casting has revolutionized creativity in art & sculpture. For instance, artists & sculptors use cutting-edge techs like rapid prototype aluminum casting & rapid prototype sand castings to open up new artistic expressions.

In the meantime, rapid prototyping investment casting precession ensures that it recreates intricate details. Above all, artists can explore rapid prototyping sand casting molds to create unique textures and forms.

Robotics & Automation

Rapid prototype casting facilitates tech innovation in robotics & automation. Overall, rapid prototyping techs such as investment casting rapid prototyping & rapid prototype aluminum casting have transformed the industry. Simply put, rapid prototyping investment casting offers precession in intricate components for robots.

Moreover, rapid prototype casting provides a platform for rapid innovation. In general, engineers & designers can use rapid prototyping sand casting molds to iterate & refine robotic prototypes. Thus, the tech ensures faster development cycles and reduced costs.

Education & Research

In general, integrating rapid prototype casting technologies has revolutionized research & education. In the meantime, casting rapid prototyping, investment casting rapid prototyping, & rapid prototype aluminum casting have opened avenues for learning.

In any case, students benefit from rapid prototyping investment casting for precision in creating intricate models and components in science. Furthermore, rapid prototype casting in research accelerates innovation since scientists can use rapid prototyping sand casting molds to produce prototypes for experiments.

The Future of Rapid Prototype Casting

Overall, the future of rapid prototype casting holds immense promise and potential across various sectors. Meanwhile, Rapid prototype casting encompasses techniques like investment casting and rapid prototype aluminum casting that evolve. Thus, the future presumes more comprehensive materials for rapid prototype casting.

In general, the ongoing refinement of casting rapid prototyping techniques will lead to greater precision and accuracy. In any case, rapid prototyping and digital sand casting services will integrate with digital design and simulation tools.

Generally, rapid prototyping investment casting drives breakthroughs in the medical field through custom implants and prosthetics. In the meantime, industries like robotics and automation will benefit from rapid prototype casting as they develop advanced features. Above all, the adoption of rapid prototype casting will grow globally.

Rapid Prototype Casting Legal and Ethical Considerations

Rapid prototype casting legal considerations encompass many practices, including investment casting rapid prototyping and rapid prototype aluminum casting. In any case, one critical area of concern is intellectual property protection.

Thus, protecting your intellectual property is crucial when engaging in rapid prototype casting. In addition, this safety consideration includes establishing robust trademarks, copyrights, and patents on your innovative concepts.

Overall, navigating international laws & regulations is vital since different countries have distinct legalities. Thus, addressing the considerations ensures that your rapid prototype casting endeavors are ethically responsible, legally sound, and innovative.

Rapid Prototype Casting Vs. Traditional Prototyping

In general, rapid prototype casting and traditional prototyping are product development and testing approaches that suit diverse needs. Thus, rapid prototype casting leverages advanced technologies and materials to create detailed and functional prototypes. Furthermore, rapid prototype casting offers fast turnaround processes.

On the other hand, traditional prototyping methods may require extensive tooling and labor, while rapid prototype casting minimizes tooling and reduces labor costs. In the meantime, rapid prototype casting offers various material choices. Overall, rapid prototype sand castings & investment casting rapid prototyping techs achieve accuracy.

Conclusion

Overall, rapid prototype casting has transformed various industries in designing, developing, and producing components. Above all, rapid prototype casting will reshape industries and drive innovation. Are you ready to harness rapid prototype casting?

Visit KDM Fabrication today and discover how their expertise can elevate your prototypes. The company offers expert advice on how to attain the best results in this niche. Contact KDM Fabrication today and bring your innovation or idea to life.

Frequently Asked Questions

- What are the key factors to consider when choosing materials for Rapid Prototype Casting?

Several crucial factors matter when selecting materials for rapid prototype casting. Overall, the intended use and the mechanical properties required are vital.

- Can you use Rapid Prototype Casting in large-scale production?

Rapid prototype casting suits small-scale and large-scale production since it is versatile. Therefore, it is suitable for producing a wide range of quantities.

- How does Rapid Prototype Casting ensure the accuracy and functionality of prototypes?

Overall, rapid prototype casting guarantees the accuracy and functionality of prototypes. In general, it uses 3D printing to create the master pattern with exact replication.