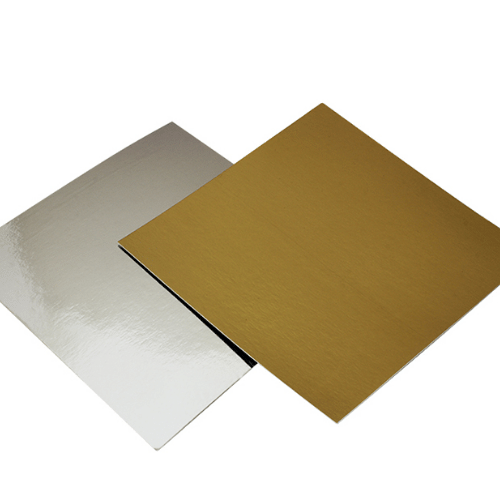

Sublimation Aluminum Sheet

Sublimation aluminum sheet is ideal for producing different aluminum products including occasional, thanking, awards, and more souvenirs. The aluminum sheet that has a printed design is attached to an MDF underlay. It improves the finished product’s visual quality so it can be hung on a surface. These are also used for making cookware, durable sidings, guttering, kitchen utensils, and more.

The transparent film of the sheet should be removed before undergoing a sublimation process. Through the dye sublimation printing process, the aluminum sheets can be printed with high-quality digital images through special sublimation inks, heat press, etc.

| Category | Sublimation |

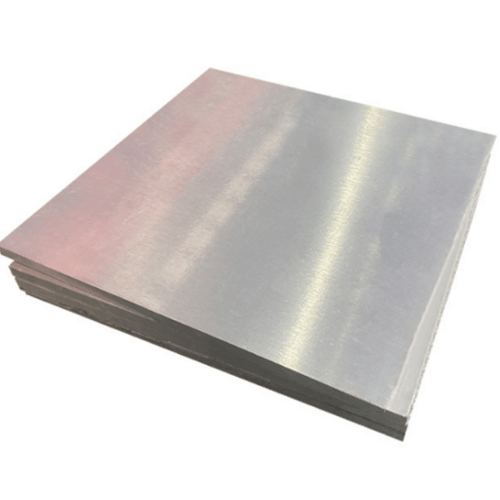

| Material | Aluminum |

| Product Type | Metal Sheet |

| Ply(Layers) | 1 |

| Technology Types | Sublimated |

| Thickness | .020”, 0.25”, 0.30”, 0.45”, etc. |

| Finish | Gloss, Brushed, Lacquered, Matte, Satin |

Sublimation Aluminum Sheet Technology

Sublimation Aluminum Sheet Fabrication

KDM has full capabilities in providing sublimation aluminum sheets. In sublimation printing, the inks are heated and then pressed into the aluminum sheet. Therefore, the printed designs we produced are guaranteed to have high resiliency. Our sublimation on aluminum sheet provides designs that are:

- Elegant

- Durable

- 3D appearance

- Design and Print. The first step on sublimation aluminum sheet is creating a design using Photoshop or other computer program. Once the design is created, it is transferred to RIP software and printed to the sublimation paper.

- Heat Press Preparation. Heat press should be prepared prior to the actual usage. The recommend temperature is 400⁰ However, it also depends on the type of aluminum used. Aside from that, substrate should also be prepared to make sure that the surface is clean. The aluminum sheet is placed to the heated press.

- A moderate pressure should be used when performing the pressing procedure. Depending on the aluminum sheet, the time to keep the substrate presses ranges from 90 to 120 seconds. Thus, giving time to ink to penetrate to the aluminum surface.

- Removing the Aluminum Sheet from the Heat Press Machine. When removing the aluminum sheet from the heat press machine, you should always wear a heat resistant gloves.

Special sublimation inks are recommended to be used for sublimation aluminum sheet since it can provide a protective coating layer on the aluminum. Some of the sublimation inks are aqueous inks for large format printers. Solvent type inks are also used for wide head printers.

Digital printing uses images that are directly printed to aluminum sheet surface. The design is printed on the top of the aluminum protective layer making the result much different from sublimation.

Sublimation on aluminum sheets heats the ink to be used so it can penetrate the aluminum protective layer. Therefore, the design are much durable and protected.

It takes 60-90 seconds to sublimate aluminum depending on the artwork and size of the substrate.

Sublimate aluminum at a temperature of 375-400°F

Some of the benefits include:

- Easy to clean

They can be wiped clean regularly without ink smearing.

- Lightweight

Their lightweight properties make them easy to mount on different surfaces.

- Scratch resistant

The dye becomes part of the product infused with the metal and thus won’t scratch off.

- Multiple finish options

They are available in many finishes giving you any look you want for your product, e.g. white, satin gold, satin bronze, satin silver, satin gold, satin, and bronze.

- Long-lasting and bright color

Special dyes are bonded permanently to the aluminum retaining their colors for years.

- Heat resistant

Industries with high temperatures use the products without melting or running.

- Great for small runs

It is great for photos, nameplates, business cards, seating, locker tags, and plaques.

- Fire retardant

Sublimated aluminum withstands extreme heat.