What Is 6061 Aluminum Alloy?

The 6061- aluminum alloy is more common and can be found in every market today. It has good resistance to corrosion, weldability, above-average strength, and machinability. Besides, strengthening of aluminum 6061 alloys can be done using heat treatment. The common types of aluminum 6061 alloys are 6061-T4 and 6061–T6.

What Is 5052 Aluminum Alloy

The 5052-grade aluminum alloy is excellent due to its weldability, good product finish, and significant resistance to salt water corrosion. It is, however, not easy to machine. And cannot be heat-treated. Besides, you can strengthen it through the process of work-hardening.

Additionally, it is known to be the strongest alloy among those that are not heat-treated. Moreover, this alloy has a lower density than pure aluminum. Some of the alloying elements are 2.5% magnesium and 0.25% chromium. Moreover, its resistance to salt water corrosion makes it an excellent choice for maritime applications

Benefits Of Aluminum 6061

Some of the benefits of aluminum 6061 alloy include:

- It has a good overall strength

- It has excellent workability and machinability.

- High resistance to corrosion hence very durable

- The excellent forming ability allows for making different product shapes

- It has great weldability

- It is heat treatable

- Affordable price

- Excellent response to anodizing, color dying, and hard coating

Benefits Of Aluminum 5052

It’s key benefits include:

- 5052 alloys have good weldability and are more preferred in pressure vessels

- Good corrosion resistance.

- High fatigue strength

- Good drawing properties

- High rate of work hardening

- Good efficiency

- The weight depends on the sizes of metal

- Durable due to its toughness and strength

Comparing 5052 Aluminum And 6061 Aluminum

5052 and 6061 alloys are used for differing purposes.

5052 is excellent for making sheet metals and welding. On the other hand, 6061 is best for machining applications. Additionally, it is more difficult to deform 6061 alloys permanently than 5052 alloys. Besides, 6061 has a yield strength of 276 MPa compared to 193 MPa for 5052 alloys.

Chemical Properties Of 5052 vs. 6061 Aluminum

Chemical composition of 6061 Aluminum is;

- 90% Aluminum

- 15% magnesium,

- 70% iron,

- 2% manganese,

- 0,80% silicon,

- 4% copper,

- 25% zinc,

- 15% tin and

- 35% chromium.

Chemical composition of 5052 aluminum is;

- 85 – 97.70% Aluminum

- 80% magnesium,

- 40% iron,

- 10% manganese,

- 0,25% silicon,

- 00% copper,

- 10% zinc,

- 35% chromium.

Mechanical Properties Of 5052 and 6061 Aluminum

Yield strength –5052 has yield strength and ultimate strength of 193 MPa and 226 MPa respectively. 6061 has 276 MPa and 301 MPa values respectively. In this case, 6061 is stronger than 5052 aluminum.

Thermal conductivity – Both 5052 and 6061 have good thermal conductivity. 6061 alloy has a higher conductivity than 5052.

Shear strength – 5052 has a shear strength of about 138 MPa while 6061 has 207 MPa. This indicates how much 6061 alloy is stronger than 5052 alloy concerning shear strength.

Machinability – 6061 is more machinable than 5052 aluminum. It is brittle and fractures off easily and gives fewer chips during machining.

Modulus of elasticity – 5052 alloy has a higher modulus of elasticity of about 70.3 GPa. It is preferred in projects that need elasticity.

Material hardness – 6061 is more resistant to penetration. It is harder to deform than 5052 aluminum.

Electrical resistivity – 5052 alloy has about 7% less electrical conductivity than 6061 aluminum.

Corrosion Resistance Properties Of 5052 vs. 6061 Aluminum

Exposure of aluminum alloys to air results in the formation of an oxide layer. The layer makes the aluminum alloy to be non-reactive to corrosive substances. Remember, the absence of copper in 5052 alloys makes them cope well in moist environments.

It is more preferred in marine and chemical applications than 6061 alloys. When both 6061 and 5052 alloys are exposed to alkaline soil a pitting reaction occurs. 5052 and 6061 alloys have magnesium which resists corrosion. An aluminum coating is used on alloys to act as a protective layer and avoid corrosion.

Weldability Properties Of 5052 And 6061 Aluminum

Both 5052 and 6061 alloy aluminum are characterized by excellent properties of weldability. Of all aluminum alloys, 5052 alloys have the best welding properties. Its formidability feature makes it perfect for the fabrication of electrical enclosures. 6061 alloys require proper selection for filler metal during welding aluminum. For good finish products, you must apply post-weld aging and heat treatment.

Applications of 5052 Aluminum

5052 aluminum alloys are resistant to seawater corrosion.

This resistance allows it to be used in marine structures such as ships and boats.

5052-grade aluminum is used in kitchen cabinets, fans and blades, fencing, appliances, clock plates, and home freezers.

It is used in manufacturing sheet metal works, chemical drums, rivets and wire, heat exchangers, pressure vessels, flooring, and panels treadplate

It is used in various transportation sectors such as bus manufacturing, aircraft manufacturing, truck manufacturing, road signs, name signs, fuel lines, street lighting, and fuel tanks.

6061 Aluminum Application

6061 Aluminum grades are used in making sailboats, yachts, hardware, and marine fittings

It is used to make various parts of automobiles, such as brakes, hydraulic pistons, and wheels, and some transportation end uses trucks and bodies for buses.

You can use it to make aircraft fittings and structures.

6061 Aluminum grades are used to make railway car components

Some home furniture, moldings, awnings, and appliance fittings are made using 6061 Aluminum alloys

Some of the most common applications food storage cans, cooking appliances, and beverage cans are made using 6061 Aluminum alloys.

Some of the most common uses miscellaneous are pipe fittings, hinge pins, bridge components, valve and valve parts, bike frames, scuba tanks, fire ladders, camera lens mounts, couplings, fittings, and connectors, magneto parks, frames, base plants, and gussets.

People also ask:

Yes, you can bend aluminum 5052. It is the best aluminum alloy for bending applications. Besides, it’s high tensile strength and yield strength when compared to other alloys that are non-heat-treatable.

Aluminum 5052 cannot be heat-treated. It can only be strengthened through strain-hardening, cold working, and hot working processes. 5052 alloys have elements that are insoluble at all temperatures.

Both alloys have their advantages. The alloy chosen is dependent on the needs and requirements of the application it is used. It is difficult to determine definitively which alloy is stronger.

Some of the most common options are:

- Aluminum sheets

- Aluminum bars

- Aluminum angles

- Aluminum plate

You can get any of the following options:

Treadplate/patterned sheet,

Plate,

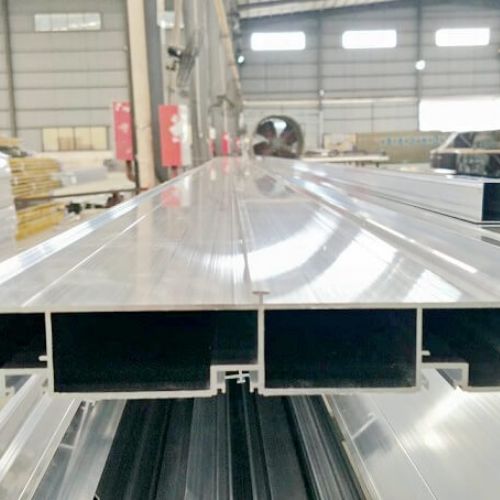

Extrusions,

Sheet

More Resources: