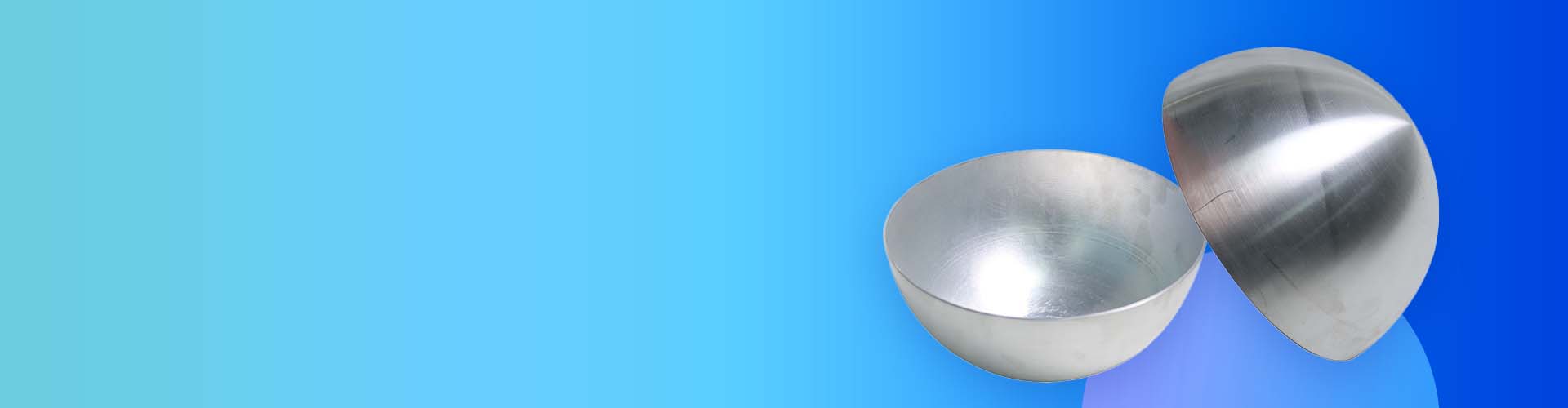

Your Sheet Metal Dome Fabrication Supplier

Otherwise called doming, sheet metal dome fabrication is a method of converting sheet metals into dome products. It is commonly made of stainless steel and aluminum sheets.

KDM Sheet metal domes are mainly used in connection with membranes, flex circuits, or PCBs. We can shape them in numerous forms such as triangle, four-legged, round, oblong, or custom. They are used mostly for electronic industries.

If you need a professional manufacturer for your sheet metal dome fabrication needs, you can trust KDM. We use different tools and equipment in the fabrication. We used a hand torch, flat file, dividers, sheet metal, and so on.

Please message us with your inquiries!

Sheet Metal Dome Series

Copper dome pendants are used as task lighting. With dynamic and bold designs, these domes are ideal for any commercial and residential furnishing. It has a polished finish.

Spinning dome covers are usually used as food covers. Known as cloche domes, they are used to keep food warm at fancy tables. It is made from copper, aluminum, or steel.

Brushed stainless steel dome is designed with excellent durability and ultimate strength. Used in architectural communities, these domes are aesthetically pleasing.

Aluminum dome is a self-reliant cover typically used in tank farms and refineries. It protects the storage item and the basic tank parts against atmospheric influences.

Decorative domes are commonly used as fire pit covers, vacuum chambers, vacuum domes, steel end caps, or domed garbage can tops. They have anti-corrosion properties.

Copper lampshade domes are attractive lighting equipment. It is perfect for commercial and home fit-outs. Plus, they also come in a polished and stylish finish.

Features of Sheet Metal Dome

Every dome design has excellent strength. Aside from that, they offer attractive appeal and durable properties.

Allow us to custom your sheet metal dome requirements. We can provide custom cut, thickness, and coating.

Even exposed outdoor, our sheet metal domes can resist any weather condition and remain corrosion-free.

We provide sheet metal domes with accurate structure and high precision. All types can benefit your business.

What is the Process of Sheet Metal Dome Fabrication?

In the first step, we cut the flat sheets –common cuts between 6 and 8mm. We used advanced cutting tools to fit required hemisphere shapes and sizes.

The second step is the shaping process. Once the flat sheets have been cut, their edges are formed for complete smoothness. After that, we refine the shape.

Lastly, the finishing process. We offer custom finishing services such as chrome coating, powder coating, anodization, bead blasting, and so on. We will base our finishing production according to your surface coating requirements.

Sheet Metals We Can Make

We provide a wide range of sheet metal options for custom domes fabrication. Whether the domes are supposed to use in the lighting industry, architecture, or decorations, we can determine the right materials to use for every purpose.

Our professionals make use of sheet metals like galvanized steel, copper, zinc, stainless steel, bronze, and more. These materials have high strength and durable properties, making the final domes possess an attractive appearance.

The sheet metals selections are also easily repairable when misfortune occurs. We also make sure our sheet metal domes offer excellent accents and features to blend well with your industrial applications.

Machining Capabilities

KDM fabricate different specialized dome and components in different dimensions and figures. We invested in the latest processing and machine technology –this is to ensure precision and quality. We also have cutting machines, bending, laser cutting, milling, and complete drilling tools.

We continue to improve our production capabilities and provide the newest innovations to guarantee better quality custom domes.

KDM is more than glad to help you with your sheet metal dome requirements. We can also determine which fabrication method would fit best for your application needs.

About KDM Capabilities

KDM, along with our fully attentive craftsmen has tirelessly worked to provide outstanding quality domes. We serve many different industries including lighting, electrical, industrial, commercials, architecture, and more.

Our team is capable to provide full sheet metal fabrication services. During product development, we give careful attention to details. We can provide customization services according to your required sizes, shapes, and details.

You are in good care with KDM. We are working with our skilled project managers, engineers, and designers to obtain an accurate final outcome. In fact, we are experienced in performing different fabrication techniques like welding, surface treatment, cutting, and more.

Let us assist your projects requiring our sheet metal dome fabrication.

KDM: Sheet Metal Dome Supplier in China

We used 3 major types of equipment in processing sheet metal domes. We work with:

- Sheet metal bending equipment –We bend sheet metals with high accuracy. One of included equipment for bending is benchtop budget brakes.

- Sheet metal forming equipment –Forming the sheet metal process requires force. This is to successfully deform the material by stressing the metal behind its elastic limit. One of the most required tools in the process is shrinker expanders.

- Sheet metal shearing tools –It is a process where metals are cut in a straight line –particularly making angled cuts. The tools used are throatless hand shears and throatless rotary shears.

Custom sheet metal domes are highly required in many applications and industries. Every type is designed for a different application, whether in the lighting industry, architectural industry, or roofing applications.

- Lighting industry: They are known as pleural dome lights when used in the lighting industry. It is often installed on the ceiling of a building, room, vehicle, or room. Provided with safety features.

- Architectural industry: Dome has hemispherical forms and is used as ceiling fixtures and decorations for architectural buildings. It is found usually in small buildings and further architectural structures.

- Roofing: Domed roof is a roof with dome-shaped designs. They are identified with onion and cone-like figures.

OEM/ODM Sheet Metal Dome Fabrication

The metal domed cover is widely used in vehicles, dryers, washers, kitchen equipment, bicycle, and engineering machinery. The domed cover is made from stainless steel, aluminum, copper, brass, and many more.

The dome lamp shade parts are available in many finishes such as porcelain enamel. It is also coated with many colors like red, green, blue, or customize.

The aluminum domed knurled knob ensures a unique finish and comfortable design. A variety of materials, sizes, and designs are available for your custom requirements.

Stainless steel metal dome is an elastic component used in the electronic and mechanical industries. It is designed to control mechanical movements such as the control and valve shrapnel. These kinds of the dome can absorb vibration and gives impact energy.

The copper dome roof is extremely light. It is widely used in most residential and commercial structures. The domed roof made from copper is known for its durability, beautiful appearance, and form complex shapes ability.