KDM - Sheet Metal Cone Fabrication

Sheet metal cone fabrication involves several machining techniques. Laser cutting, rolling, bending, welding, drilling, punching, and burning are a few. Cones are helpful in aerospace, architecture and construction, energy, medical, pharmaceutical, military, filtration, etc. It has a wide range of applications in various industries.

KDM is an expert variety of metal fabrication services; among them is sheet metal cone fabrication. Making sheet metal cones requires a great deal of skill and precision. That’s what KDM is honored for. We can make different types of cones for you.

Materials include stainless steel (304&316), steel, carbon steel, aluminum, alloys, and iron. KDM capabilities range from design, and engineering, to testing. We can customize sheet metal cone fabrication based on your industry requirements.

Please feel free to contact us for a quote.

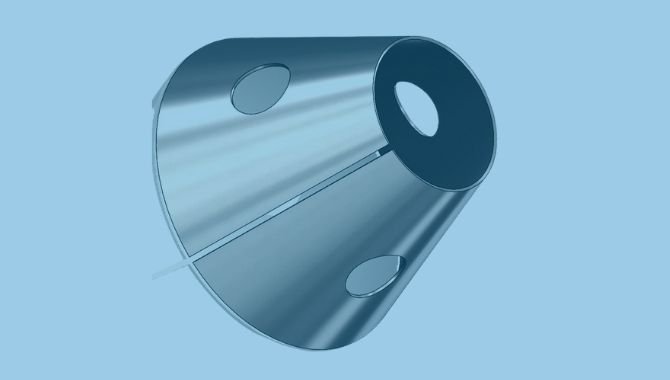

KDM Sheet Metal Cone Fabrication

The 304-grade stainless steel sheet metal cone is widely used in the chemical and pharmaceutical industry for collecting or conveying bulk solids, liquids, or gasses. It has a smooth finish, high strength, and resistance to corrosion.

The aluminum sheet metal cone is commonly used in the production of automotive parts, electronic parts, lampshades, containers, medical equipment, and many more. It is designed with high resistance to temperature and corrosion.

The iron hollow sheet cones can be applied with various surface treatments to enhance their strength and resistance to corrosion. They are commonly used for the production of loudspeaker boxes, electrical machines, and auto parts.

The copper sheet metal cone is made from high-strength and durable copper. It has a shiny polished surface. Additionally, it can be used in the electrical, machinery, and automotive industries. It is scratch-resistant, easy to clean, and rust-resistant.

The stainless steel sheet metal cone nozzles can be used for different types of spray systems such as water spray systems. They have a hollow design that provides an even distribution of spray patterns. Also, they are rust-resistant.

The hollow sheet metal cones are widely used in the automotive, construction, and agricultural industry. They are highly resistant to corrosion, rust, and chemicals. Also, they can be manufactured using aluminum, stainless steel, and more.

The lampshade sheet metal cones are commonly made from superior grade aluminum sheet metal that resists corrosion. They are widely used in the production of lampshades. Moreover, they have a shiny polished surface that reflects light.

The galvanized sheet metal cones have excellent durability and corrosion resistance due to the applied zinc coating. When they are exposed to humidity or moisture, they will not rust. They are commonly used as funnels, covers, reducers, etc.

Metal Cone Usage & Market Served

Cones are utilized as funnels, hoppers, transitions, chutes, pipe reducers, or increases in various industries. The usage varies on material qualities. As per, lightweight sheet metal cones, they are frequently used in metal ductwork – ventilation systems. Whereas, large plate cones are employed in the metal ductwork. It is mostly seen in steel mills and other big production applications.

Moreover, KDM serves the following industries:

- Construction

- Architecture

- Refining

- Petrochemical

- Manufacturing

- Food Processing

- Oil and Gas Production

- Automotive

- Electronics

- Aerospace, and among others.

Qualities & Features

Sheet metal cone fabrication qualities differ on various factors in specifications. It involves required metal cone strength, standard requirements, material characteristics, etc.

Nevertheless, the most common material qualities include heat resistance, corrosion resistance, impact resistance, and wear resistance.

The metal cones comprise multiple capabilities. It encompasses offset reducers, concentric reducers, segmented reducers, transitions, and more to go.

Why Choose KDM to Custom Metal Cone Fabrication

KDM is a professional manufacturer providing custom cone fabrication services. For more than 10 years, we are cooperating with many industries and sectors. We provide complete customization services for your metal cone. From choosing the right material, prototyping, full metal fabrication, quality testing, and so on.

Our innovative manufacturing plant has all tools and equipment to make structural grade cones. Whether lightweight or heavy applications, we can make the best component for you. Our team can work with extreme precision so we can exceed your final applications. You can guarantee the final prototype is just what you envisioned.

Regardless of your project demand, KDM can help you build an OEM metal cone. Before production, CAD and Solidworks drawings would be provided for your approval. Contact us to execute professional custom metal cone fabrication.

KDM Sheet Metal Cone Fabrication

Sheet metal cone fabrication is made up of several metalworking processes. KDM keeps our options open to construct unique mechanical assemblies. We’ve summarized the metal cone fabrication processes.

- Cutting – entails piercing the workpiece with a sharp instrument to remove a portion of the metal.

- Bending – by generating an angle or curve in the metal piece

- Forming – molding metal into a cone shape by molding or forging it.

- Machining – the process of turning, milling, drilling, shaping, or remodeling a workpiece

- Assembling – assembles the metal components while the production process is running.

As an expert manufacturer, KDM is capable of providing OEM cone fabrication services.

We’d consider multiple specifications such as required material characteristics, product reliability, cone volume request, and purposes/applications.

At KDM, we can make almost any type of custom sheet metal cone product. We can customize the size, shape, materials, complexity, and other aspects. In addition, the fabrication process can also be tailored.

Speak with us to learn more about custom metal cone fabrication.

Custom Sheet Metal Cone Fabrication

The stainless-steel cone can be polished, anodized, or chrome plated. Because of its unique coating, the cone can guarantee corrosion resistance and durability. They are also rust-resistant.

A custom copper cone cap is designed to produce an effective and pleasing protective barrier between the elements and wood pilings. These cone caps are beautiful and ensure an effective and snug fit.

The deep draw stainless steel cone is widely used for auto exhaust systems. They are available in many coatings such as galvanizing and chrome plating to ensure durability and high performance.

The aluminum metal spinning cones have numerous angles and styles options such as bolt circles, flanges, and holes. These cones are widely utilized in different industries like agriculture, marine, oil and gas, architectural components, and many more.