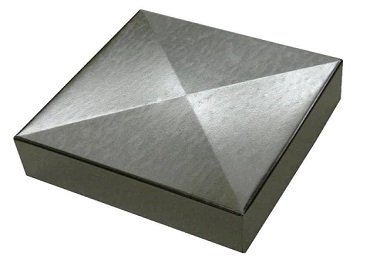

Custom Sheet Metal Beam Caps

Sheet metal beam caps provide excellent wooden roofing beams protection from sun and water damage. It is made from versatile metals such as stainless steel, copper, galvanized steel, etc.

- Durable metal materials

- Corrosion-resistance

- Custom design to fit your beam

- Easy to install, maintenance-free

- Various color options

- Provide structural support

- Product Details

- Gallery

- Classic and aesthetics architectural style

- Durable and scratch-resistant

- Temperature resistant

- Made from easy formability and fabrication materials

- Smooth and attractive appearance

- Environmentally friendly (recyclable)

- Available in silver, matte black, brown, white color, etc.

Materials for Your Metal Cap

KDM sheet metal beam caps are manufactured from durable materials such as steel, galvanized steel, stainless steel, copper, and other metal. We work with various metals based on your requirements.

Our team has excellent metal beam caps fabrication techniques and rich experience in this industry. We provide efficient sheet metal beam caps fabrication at low MOQ. Message us today!

Sheet Metal Beam Caps Applications

KDM sheet metal beam caps are the ideal choice for numerous construction projects and industrial and residential roofing applications. All of these beam caps are made from premium quality metal guaranteeing long-lasting beam protection from harmful weather and sun damage.

As your professional manufacturer, KDM supplies a wide range of metal beam caps in all sizes and shapes. These products follow strict quality control and inspection. At KDM, you can request custom-designed sheet metal beam caps according to your specifications.

Custom Sheet Metal Beam Caps

For your custom sheet metal beam caps fabrication, you can trust KDM. KDM has 10+ years of manufacturing experience in China. We offer different sheet metal beam caps service capabilities including cutting, slitting, bending, shearing, blanking, leveling, brushing to surface treatment, and assembling.

You can send your beam caps drawing or sample. Choose the size, materials, designs, features, and other specifications to meet your needs. Our skilled team can handle rapid prototyping and mass production.