Steel is one of the most versatile and reliable materials used in the construction process. And, in many ways, its functionality boils down to the fact that it is so flexible.

For that flexibility to be achieved, structural steel fabricators do a great deal of work to optimize its initial fabrication process. Let’s take a look at how this process works

Structural Steel Fabrication: A General Process Overview

Optimizing the use of steel requires several steps. And, one of those is structural steel fabrication.

When it comes to this process, you have a structural steel fabricator whose main objective is to use different intricate structural steel fabrication methods to create a steel material or component that can work for its intended purpose.

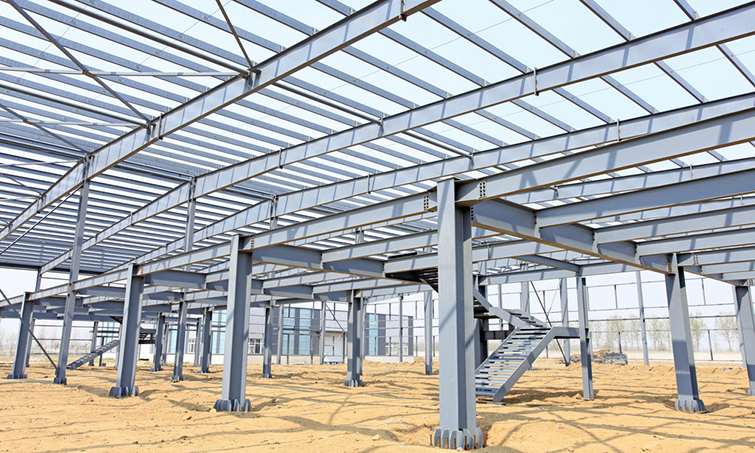

Generally, you have different facets of the structural steel fabrication process. From shaping to trimming and more, all of these ensure that you can use steel to form various elements and builds. As we know, some of the most prominent variants of steel include beams, columns, pipes, and more.

Overall, the goal remains the same – using creative and innovative processes to create steel parts that you can use for different tasks – as well as combine and mic to form more complex components. These fabricated parts are then used to make bridges, buildings, and other infrastructural developments.

What Are The Most Common Types Of Steel That Are Used In This Process?

One of the major reasons why steel is so popular is that is comes with impressive variance. And, just as you have different grades and types of the material, you also have to find out how best to work with them if you’re a fabricator.

Fortunately for you, structural steel fabrication works for several grades of the material. The most ASTM standards for structural steel fabrication prominent of these include;

- ASTM A36: The ASTM A36 grade is one of the most popular steel grades available. Known for its optimal mechanical properties, the grade offers a proper balance of weldability, strength, and ductility.

- ASTM A572: Known as a high-strength, low-alloy (HSLA) grade, this option is used in applications that require optimal strength and corrosion resistance. You can also find it in different grades, so being particular about your options is critical here.

- ASTM A992: Next, we have a high-strength steel grade that has been dubbed by many as the “W shapes” grade. It is also used in structural applications, with a top minimum yield strength of 345 MPa.

- ASTM A500: This steel standard generally covers seamless, cold-formed carbon steel tubing – which can be obtained in different shapes. In general, it is used in developing building support structures.

- ASTM A36/A36M-08 Structural A-36 Steel: A carbon structural steel, this variant offers impressive mechanical properties and can easily be modified or machined.

- ASTM A588: This steel grade is mostly known for one thing – atmospheric corrosion resistance. Used in building outdoor structures, its high strength makes it a viable long-term option.

- ASTM A514: ASTM A514 is a quenched and tempered steel alloy that works in applications that require optimal toughness across the board. It is also very weldable – a factor that expands its possible functionality.

- Stainless Steel: In some cases, you can also find stainless steel being fabricated and used for structural purposes. The material is also resistant to considerable corrosion, and you can easily machine it for use.

Like many other options on this list, you can find this specific material in different grades. So, having a perfect understanding of the different available options – as well as their different characteristics – is important if you’re to ensure efficiency.

Structural Steel Fabrication: Preparing Your Material Checklist

The process of structural steel fabrication relies on the use of different equipment and tools that help to deliver steel of the right specifications and requirements. As you can expect, the specific tools you use will differ based on your requirements.

To aid your preparation, here are a few of the most important tools applied in this process:

Cutting Tools:

To achieve the right cut, you want to have the following:

- Circular Saw: The circular saw is mostly used to achieve sharp, straight cuts in steel profiles.

- Band Saw: If you’re looking to make beams, pipes, or other components with irregular shapes, a band saw is a much more ideal option than the circular saw.

- Plasma Cutter: The plasma cutter is known for its speed and precision, applying high temperature jets at impressive velocities to achieve the perfect cut.

- Oxy-fuel Torch: You could also go for the oxy-fuel torch,which cuts through steel plates with an intricate combination of fuel gas and oxygen.

Shaping and Forming Tools:

When the steel has been cut, you will need to shape it to the right specifications. For this to work, some tools that could be applied include:

- Press Brake: The press brake helios to bend steel profiles when you need to create complex details like curves and angles.

- Rollers: With a roller, steel sections and plates are properly rolled to form circular-based components like cones and cylinders

- Shears: You can use a shear to cut through steel plates, creating the proper size and shape specifications.

Welding and Joining Tools:

As part of structural steel and plate fabrication, you would also need to properly join steel components together. This helps in creating the desired shapes and structures themselves. And, some of the tools that assist with this include:

- Welding Machine: You can find different types of welding machines that aid this operation. Some of the most important include Metal Inert Gas (MIG) welders, Tungsten Inert Gas (TIG) welders, and more.

- Welding Torch: With a welding torch, you can easily control and direct the heat and filler material that will be used in welding joints.

- Welding Positioners: A welding positioner is a machine that helps to rotate and position your steel components to ensure precise welding outcomes.

Assembly and Handling Tools:

Assembly tools help put steel components together as well – especially those that need to be combined to form the desired shape. A few prominent assembly tools in steel structure fabrication include:

- Overhead Cranes: In your fabrication shop, you need an overhead crane to lift those objects that can’t be moved by human hand.

- Chain Blocks and Lever Hoists: Chain blocks assist in manual object lifting processes, while also helping you to position the steel elements properly.

- Clamps and Fixtures: Your clamps will be used to keep steel components in place as you weld.

Surface Treatment Tools:

To ensure optimal surface treatment, you want to make use of one or more of the following structural steel fabrication equipment:

- Grinding and Sanding Tools: Your fabricated steel structures are bound to have rough edges. With grinding and sanding tools, you can easily smoothen these out. Take out burrs, smoothen your edges, and prepare your steel surfaces for welding.

- Power Brushes: Right before coating or painting, you can apply a power brush to properly clean your steel surface.

- Spray Guns: A spray gun helps to apply the right paint and primer to your steel components.

Measuring and Layout Tools:

It is important for you to take out the time to also ensure that your steel materials meet your desired measurements. Traditional layout tools that are common in the steels structure fabrication process include:

- Tape Measures, Calipers, and Micrometers: There’s no doubt about these. They help ensure optimal measurements and dimensions, keeping your steel products in check.

- Levels and Squares: For perpendicular alignment, squares and levels are required.

- Marking Tools: You can also use markers, chalk, and scribes to mark cutting lines and reference points on any of your steel surfaces.

The Complete Roadmap: How Steel Is Fabricated

So, we get to the main point of discourse – how do structural steel fabrication companies achieve the perfect steel materials?

Generally, the process can vary based on the company handling the project and the required specifications of the steel. However, at KDM Fabricators, we follow this outline when it comes to creating a fabricated steel structure:

Design and Engineering:

The first step should be a design of the desired steel product. Here, the design team creates detailed drawings, plans, and specifications for the fabricated structural steel, putting its use and requirements into consideration. It is important to know how to read structural steel fabrication drawings here, as it will help to ensure a smooth workflow.

Engineers will also need to analyze factors such as load requirements, local regulations, and more to determine the right steel connections and sections.

Material Procurement:

Once everyone is on the same page as to what they would like their steel to be, you can move on to purchase the required materials. You can get steel material suppliers to deliver the raw materials, although it is important to ensure that the steel meets the required quality standards.

With our network of suppliers, we have been able to ensure that this process goes off without a hitch. And, if you need any help with procuring materials, you can also contact us at KDM Fabricators.

Material Preparation:

Next, you inspect the steel material once they arrive. Defects or damage in the materials could lead to fabrication errors in steel structures, so it is very important to ensure that all of your steel materials are in top shape.

Then, you can go on to cut your raw steel – whether in plates, sections, or whatever specification suits your application. Remember the required length specifications and your design requirements here.

Finally, you’d need to prepare your steel plate surfaces. This can be done by grinding or shot blasting; processes which will help to take out rust and other contaminants.

Layout and Marking:

Based on the fabrication drawings, you can lay out your steel components. Ensure accurate placement with your layout tools, then mark reference points and hole locations with scribes.

Cutting and Shaping:

With tools like shears and oxy-fuel torches, you can cut the steel sections and plates based on the marks you’d made. And, keep in mind that you might need to form and shape your steel sections with tools like rollers or press brakes. These help you to create custom profiles that will fit your requirements.

Material Assembly and Joining:

To ensure optimal assembly, start by positioning your steel components and aligning them based on your drawings. You can then begin welding and bolting to join the steel sections together.

While joining, it is important to keep the proper weld strength and penetration in mind. Then, you can use clamps, fixtures, and jigs to hold each component in place during the entire process.

Quality Control and Inspection:

All through the fabrication of steel structures, it is important that you maintain optimal quality across the board. So, always have an eye out for quality and implement a rigorous checking module for every step of the process.

Although you have different checks to avail yourself of, some of the most popular include dimensional assessments, weld inspections, and material tests. These ensure that you can maintain compliance with industry standards and specifications, and that the fabric covered steel structures will live up to the requirements.

You could also engage ultrasonic testing and other non-destructive inspections to detect any possible material defects.

Surface Treatment:

Once the welding and assembly operations are completed, you can apply surface treatment to protect your components from any form of corrosion. Some of the most prominent surface treatment options include galvanizing, painting, and coating applications.

Final Checks and Packaging:

You’re almost at the finish line! But, given that your steel material will be used in different capacities, ensuring its quality will be more than important.

Take the completed steel components and go through a final round of checks to ensure material quality and accuracy. Ensuring that they adhere to the minimal specifications will be important here.

Once you’re sure that your steel is up to code, package it and move them to the construction site. Packages should be properly labeled, so handling and identification can be done properly.

Steel Transportation and Installation:

The finished product is taken to the construction site – either by truck or any other transportation means. And, while on-site, cranes and other lifting equipment can be used to install them based on the construction sequence.

With effective project management and construction processes, you can ensure that the structural steel fabrication step is as reliable as possible. We at KDM Fabricators have been able to optimize our process as much as possible, and you can count on us to get you the best in quality fabricated steel.

Structural Steel Fabrication: Why This Process Matters

Over the years, more material developers have been able to take advantage of structural steel fabrication for its many benefits and potential for making their overall process easier. Some of these general advantages include:

Strength and Durability:

Thanks to the fabrication process, you can create structural steel – a material with a high strength-to-weight ratio, which can easily support heavy loads and resist different types of forces.

Heavy steel structure fabrication easily holds its own against earthquakes, wind, unfavorable gravity, and other forces. And, you can count on it to maintain this structural integrity in the long term. So, there will be a minimal need for extensive maintenance and repair.

Flexibility in Design:

Structural steel fabricators and erectors are free to be as creative as possible when it comes to their processes. They can create highly complex and intricate structures, with their components being easily fabricated and customized into different sizes and configurations.

Whatever your engineering requirements are, rest assured that we at KDM Fabricators will be able to handle them.

Speed And Efficiency:

One of the most underrated benefits of structural steel fabrication is the fact that the process is swift. Since the steel components themselves are pre-fabricated at an offsite location, the entire process is able to be completed much faster than traditional onsite operations.

All of this will result in reduced timelines and ensure that the project can be completed much earlier.

Relative Cost Efficiency:

To be fair, the initial structural steel fabrication cost can be higher than what you get with a few other construction materials. However, you should also keep in mind that the long-term benefits are much more significant.

Whether it’s the material’s process’s ability to optimize speed or cut down on labor expenses, developing steel means that you will be able to save a ton of long-term cost.Remember that steel can also be recycled; so it benefits the environment in the long run.

Fire Resistance:

A notable benefit of the proper fabrication process is that it enhances steel’s fire-resistant properties. This makes steel a preferred choice for structures where you need to maintain the highest levels of fire safety.

Besides not contributing to the spread of fire, properly fabricated steel will also hold its structural integrity at high temperatures.

Versatility and Adaptability:

Even after it is fabricated, steel can easily be expanded and modified to accommodate any changes in the building operation and layout. This flexibility allows you to easily process future additions and modifications to the building without necessarily posing any threats to its structural integrity.

Reduced Foundation Requirements:

With its high strength-to-weight ratio, steel is able to achieve lighter foundation requirements. Over time, this will cut down the need for any costly foundation work – especially in building projects that encounter challenging soil conditions.

Predictability and Consistency:

Ideally, the steel fabrication process should be conducted in controlled factory environments. This ensures that you can maintain material consistency and accurately predict the flow and parameters of the material. In general, you will find a reduced likelihood of errors this way, while also ensuring that the fabricated components meet the right structural steel fabrication tolerances and standards.

Material Safety:

When done right, the steel structures produced via this process will be of the highest safety standards. There are safety standards that have been set and which your fabricated steel materials will need to adhere to. With proper fabrication, you can achieve this easily.

As expected, the overall strength and durability of steel will also contribute to the general safety of the structure itself.

All of these benefits make structural steel fabrication jobs a very critical part of the overall construction industry as they help provide benefits across a broad range of applications.

The Industrial Applications of Structural Steel Fabrication

Merely talking about the applications of steel will probably require its own individual article. However, for a perfect illustration of this point, perhaps we should highlight some of the major areas where structural steel fabrication comes in handy:

Construction and Infrastructure:

If you say that the construction space is the one that uses structural steel fabrication steel the most, we don’t think there’d be anyone to argue with you. To prove that point, consider some of the field’s applications of this operation:

- Buildings: Developing buildings takes a lot of material work. And, over the years, steel has become a key component of this. With structural steel fabrication, we can fashion the material needed to mak buildings, warehouses, and more. The material’s strength and versatility are just some of the benefits here.

- Bridges: With the steel structure fabrication process, you can harness the material’s durability and load-bearing capacity to create bridges of different types. It is also worth noting that steel can be fabricated into different lengths and configurations, thus improving the extent of the material that is available for construction projects.

- Industrial Plants: Steel fabrication optimizes the material’s strength and resistance to harsh environments to make it more viable in the development of industrial plants and several components used there.

- Large-Scale Venues: Steel can also be fabricated into different sizes, making the material useful in developing several massive venues – arenas, sports stadiums, and more.

Oil and Gas Industry:

Moving on, we have the oil and gas industry, which uses structural steel fabrication in the following ways:

- Building Offshore Platforms: Structural steel fabrication is crucial in the construction of offshore platforms. From oil rigs to production platforms and several other subsea structures, the material’s corrosion resistance and high strength come in very handy in this application.

- Pipelines and Storage Tanks: Oil and gas will need to be stored in tanks. And, these tanks are made of fabricated steel, with the material’s durability and corrosion resistance also coming in handy.

Manufacturing and Industrial Equipment:

For manufacturing, several of steel’s most significant properties mean that the material helps in building some of the following:

- Industrial Machinery: With properly fabricated steel, we’ve been able to build several of the most impressive machines known to man.

- Conveyor Systems: With conveyor systems, steel is applied in material handling for industries such as agriculture, mining, and overall manufacturing.

Automotive and Transportation:

Everyone needs traditional transportation to get from one palace to the other. And, with the heavy use that transportation lines and vehicles get, steel has become especially popular in ensuring long-term functionality.

To that end, some of the critical functionalities of this step in the movement of people can include:

- Automotive Industry: Structural steel fabrication is a significant part of developing automobile frames and vehicle components. The material’s strength and impact resistance make it a preferred part in several automotive functionalities.

- Railways: As for railway tracks, we see steel being used in making tracks, bridges, train components, and other essentials – also a direct consequence of the material’s strength.

Energy and Utilities:

With structural steel fabrication, we can create components and steel materials that aid in the operation of power plants – regardless of the type. Renewable energy components can also be built, with steel structures providing optimal support for critical equipment and increasingly heavy machinery.

We should also point out the use of steel in developing transmission towers and electricity distribution networks. The material’s durability and strength enable it to easily hold its own against high wind loads, thus supporting transmission lines across the board.

Mining and Minerals:

Structural steel fabrication helps in the construction of traditional mining equipment, mine shafts, and even in developing equipment for processing plants. Once again, the process’s ability to optimize steel’s resistance to harsh conditions makes it especially advantageous for this operation.

Aerospace and Aviation:

In the aviation and aerospace industry, the primary function of structural steel fabrication is in aircraft manufacturing itself. The material is used to create wings, frames, and other structural components that help in moving people from one point to the other.

Before You Begin: Critical Considerations In Structural Steel Fabrication

Now, there’s absolutely no doubt that structural steel fabrication is a reliable and effective process. However, considering how important the process is, you would want to keep an eye out for a few things before you even begin:

Design Complexity & Accuracy:

We can’t stress this enough – you need to make sure that your structural design and engineering are as detailed and as accurate as possible. This ensures that your steel material can meet the ideal project requirements and specifications.

Material Selection:

Choosing the perfect steel grade and type will also play a role in ensuring that your steel meets the right requirements – from ductility to strength and overall factor resistance.

Fabrication Planning and Scheduling:

Be sure to plan and schedule the structural steel fabrication process properly to ensure an efficient workflow and a timely product delivery. Ensure clear communication among all stakeholders and see to it that the project schedule goes off without a hitch.

Skilled Labor & Expertise:

We also recommend ensuring that everyone who works on this process is skilled enough to handle it. They should be trained in working with structural steel fabrication equipment, and they should be aware of all safety and security considerations.

Environmental Considerations:

You also need to keep an eye out for environmental factors that might affect the overall quality of your steel fabrication process.

Here, you want to maintain control over factors such as moisture, chemicals, and temperatures. You also need to ensure proper measures to protect against corrosion. With galvanization, coatings, and more, you can optimize the longevity and durability of your steel components.

Operational Safety:

This leads us to the safety of the operation itself. Be sure to implement the right safety measures to protect your workers during the fabrication process. From proper handling of structural steel fabrication machinery to wearing personal protective equipment (PPE), don;t leave anything to chance.

Transportation and Logistics:

Planning the movement of equipment and raw materials to the fabrication site – as well as moving the fabricated structural steel to the construction site – is important. Determine factors like packaging, labeling, and component security to ensure that the process goes off smoothly.

Compliance with Codes and Standards:

Lastly, see to it that your entire operation is in compliance with building codes, regulatory requirements and more. Look up the relevant structural steel fabrication standards for each process and ensure that your structure is durable and of the highest quality.

Conclusion

The process of fabricating structural steel can’t be overemphasized in terms of importance across the board. And, befitting its importance, a lot goes into making sure that it is as hitch-free and as seamless as possible.

At KDM Fabricators, we are expert structural steel fabricators who understand your needs and will be able to deliver high-quality steel materials to you. And, if you need any counsel or insights, don’t hesitate to give us a call and we will be able to lend you a hand. Request steel structure fabrication procedure PDF for more information.

Frequently Asked Questions (FAQs)

How much does structural steel fabrication cost?

The cost of structural steel fabrication will depend on several factors – including the processes you choose to involve, the type of steel you choose to fabricate, and more. You want to get a structural steel fabrication cost estimation before you begin – and, in most cases, this cost will also factor into choosing the cost of fabricated steel at the end of the day.

Are there any weight limitations when using structural steel components?

In general, structural steel components can be built to support different load ranges. However, these limitations will depend on the grade of steel, engineering considerations, and perhaps even the steel design.

What is the difference between structural steel fabrication and welding?

It’s easy to confuse both processes since they use similar operating equipment and can work hand in hand. However, it is worth noting that welding is one of the many specific steps involved in structural steel fabrication. In this context, structural steel fabrication encompasses the entirety of the processes – of which welding is one of them.